Why FEP Non-Toxic Heat Shrink Tubing is a Game-Changer for Industries

FEP Non-Toxic Heat Shrink Tubing has become a cornerstone in industrial innovation due to its exceptional properties. Industries value its chemical inertness, thermal stability, and non-toxic nature, which ensure safety and reliability in critical applications. Its ability to withstand extreme temperatures and resist harsh chemicals makes it indispensable for sectors like medical, aerospace, and chemical processing. The tubing’s durability and low shrink temperature allow it to protect sensitive components without causing damage, setting a new benchmark for performance and safety across diverse industries.

Unique Features of FEP Non-Toxic Heat Shrink Tubing

Non-Toxicity for Safe Applications

FEP Non-Toxic Heat Shrink Tubing ensures safety in environments where human contact is unavoidable. Its non-toxic nature makes it an ideal choice for industries like medical and food processing, where contamination prevention is critical. The tubing's chemical composition eliminates the risk of harmful substances leaching into sensitive applications. This feature supports its use in biopharmaceutical and laboratory settings, where maintaining purity is essential. By prioritizing safety, this tubing meets stringent industry standards and enhances reliability in critical operations.

Exceptional Heat and Chemical Resistance

The ability to withstand extreme temperatures and resist harsh chemicals sets FEP Non-Toxic Heat Shrink Tubing apart. It operates effectively across a broad temperature range, making it suitable for demanding industrial environments. Its chemical inertness ensures compatibility with corrosive substances, which is vital in chemical processing and manufacturing. Additionally, the tubing resists UV exposure, maintaining its integrity even in outdoor or high-radiation applications. These properties make it a dependable solution for industries requiring durability under challenging conditions.

High Durability and Tear Resistance

FEP Non-Toxic Heat Shrink Tubing offers exceptional durability, ensuring long-term performance in rigorous applications. Its high resistance to tearing and impact protects sensitive components from damage. This durability reduces the need for frequent replacements, leading to cost savings over time. Industries such as aerospace and automotive benefit from its robust construction, which enhances the lifespan of critical systems. The tubing's strength and reliability make it a trusted choice for protecting equipment in harsh and demanding environments.

Low Friction and Anti-Stick Properties

FEP Non-Toxic Heat Shrink Tubing exhibits low friction, which enhances its performance in various industrial applications. Its smooth surface minimizes resistance, allowing components to move freely without unnecessary wear or damage. This property proves essential in environments where precision and efficiency are critical, such as in automated machinery or medical devices. The tubing's anti-stick capabilities prevent substances from adhering to its surface, ensuring easy cleaning and maintenance.

Industries benefit significantly from these features. For example, in chemical processing, the anti-stick property prevents residue buildup, maintaining operational efficiency. Similarly, in the medical field, this characteristic supports hygiene by reducing the risk of contamination. The combination of low friction and anti-stick properties makes FEP tubing a practical choice for applications requiring seamless operation and cleanliness.

Superior Dielectric and Insulating Capabilities

FEP Non-Toxic Heat Shrink Tubing offers exceptional dielectric properties, making it an excellent insulator for electrical components. Its ability to withstand high voltages ensures reliable performance in critical systems. This feature is particularly valuable in industries like aerospace and electronics, where electrical insulation is vital for safety and functionality.

The tubing's insulating capabilities also contribute to energy efficiency. By minimizing energy loss, it supports sustainable practices in industrial operations. Furthermore, its resistance to environmental factors, such as moisture and UV radiation, enhances its longevity in outdoor applications.

According to studies, FEP tubing's electrical insulation and thermal stability make it indispensable in demanding environments, including medical and industrial settings.

These superior insulating properties not only protect sensitive components but also improve the overall efficiency and reliability of industrial systems.

Benefits of FEP Non-Toxic Heat Shrink Tubing for Industrial Applications

Enhanced Safety in Sensitive Environments

FEP Non-Toxic Heat Shrink Tubing provides unmatched safety in environments where contamination or exposure to harmful substances poses significant risks. Its non-toxic composition ensures that no hazardous chemicals leach into sensitive areas, making it ideal for medical, food processing, and pharmaceutical industries. The tubing's translucent nature allows for easy monitoring of fluid flow, which enhances operational precision in critical applications. Additionally, industries can utilize colored FEP tubing to identify transfer lines or differentiate between systems, further reducing the risk of errors.

In medical settings, the tubing supports biocompatibility and sterilization processes, ensuring patient safety. Food processing facilities benefit from its ability to maintain hygiene standards by preventing contamination. By prioritizing safety, this tubing meets stringent regulatory requirements and fosters trust in high-stakes environments.

Reliable Performance in Extreme Conditions

FEP Non-Toxic Heat Shrink Tubing excels in extreme conditions, offering consistent performance across a wide temperature range. Its thermal stability ensures that it remains functional in both high-heat and sub-zero environments. This makes it indispensable for industries such as aerospace, automotive, and chemical processing, where equipment often faces harsh operating conditions.

The tubing's chemical resistance further enhances its reliability. It withstands exposure to corrosive substances, ensuring long-term integrity in chemical plants and manufacturing facilities. Its low gas permeability prevents leaks, making it suitable for applications requiring airtight seals. Furthermore, black FEP tubing offers protection in light-sensitive environments, maintaining the quality of materials or fluids being processed. These features make the tubing a dependable choice for demanding industrial applications.

Long-Term Cost Savings Through Durability

Durability is a defining characteristic of FEP Non-Toxic Heat Shrink Tubing. Its high resistance to tearing and impact reduces the frequency of replacements, leading to significant cost savings over time. Industries benefit from its ability to protect sensitive components, extending the lifespan of critical systems. For example, in the automotive sector, the tubing shields wiring and components from wear and tear, minimizing maintenance costs.

The tubing's robust construction also supports energy efficiency. Its superior insulating properties reduce energy loss in electrical systems, contributing to lower operational expenses. Additionally, its anti-stick surface simplifies cleaning and maintenance, saving time and resources. By investing in this durable solution, industries can achieve long-term financial benefits while maintaining high performance and reliability.

Energy Efficiency in Electrical Insulation

FEP Non-Toxic Heat Shrink Tubing significantly enhances energy efficiency in electrical systems. Its superior dielectric properties minimize energy loss, ensuring optimal performance in high-voltage applications. Industries rely on this tubing to reduce power dissipation, which directly contributes to lower operational costs and improved sustainability. By maintaining consistent insulation, FEP tubing supports the uninterrupted flow of electricity, even in demanding environments.

The tubing's thermal stability further bolsters its energy-efficient capabilities. It withstands extreme temperatures without compromising its insulating performance. This makes it an ideal choice for industries like aerospace and automotive, where electrical systems often operate under harsh conditions. Additionally, its low gas permeability prevents energy leaks, ensuring that systems remain efficient over extended periods.

According to industry experts, FEP tubing's ability to maintain electrical insulation under extreme conditions sets it apart from other materials. Its unique combination of properties ensures reliability and efficiency in critical applications.

FEP tubing also supports sustainable practices by reducing the need for frequent replacements. Its durability and resistance to wear extend the lifespan of electrical components, minimizing waste and resource consumption. This long-term reliability makes it a cost-effective and environmentally friendly solution for industrial applications.

Versatility Across Diverse Industrial Needs

FEP Non-Toxic Heat Shrink Tubing demonstrates remarkable versatility, making it indispensable across a wide range of industries. Its chemical resistance and thermal stability allow it to perform reliably in environments exposed to corrosive substances or extreme temperatures. This adaptability ensures that industries can use the tubing in various applications without compromising performance or safety.

In the medical field, FEP tubing plays a crucial role in enhancing the functionality of devices. Its biocompatibility and sterilizability make it suitable for applications requiring strict hygiene standards. Similarly, in chemical processing plants, the tubing's resistance to harsh chemicals ensures the integrity of systems handling reactive substances. These properties highlight its ability to meet the unique demands of specialized industries.

The tubing's transparency and anti-stick surface further expand its applications. In laboratory settings, its clarity allows for easy monitoring of fluid flow, while its non-stick properties simplify cleaning and maintenance. These features make it a practical choice for biopharmaceutical and research environments, where precision and cleanliness are paramount.

"FEP tubing is designed to withstand extreme temperatures, chemical exposure, and mechanical stress, ensuring reliability in demanding applications," as noted by industry professionals.

FEP tubing also excels in low-pressure applications, such as fluid transfer systems, where its flexibility and durability ensure consistent performance. Its ability to adapt to diverse industrial needs underscores its value as a reliable and cost-effective solution for modern industries.

Key Industrial Applications of FEP Non-Toxic Heat Shrink Tubing

Automotive Industry

Protecting Wiring and Components

The automotive industry relies heavily on FEP Non-Toxic Heat Shrink Tubing to safeguard electrical wiring and sensitive components. Its exceptional dielectric properties ensure reliable insulation, preventing short circuits and electrical failures. The tubing's chemical resistance protects wiring from exposure to oils, fuels, and other corrosive substances commonly encountered in automotive environments. Additionally, its ability to withstand high temperatures ensures that it performs consistently near engines and other heat-generating systems. By providing robust protection, this tubing enhances the longevity and reliability of automotive electrical systems.

Enhancing Durability in Harsh Environments

Automotive applications often involve exposure to extreme conditions, including temperature fluctuations, moisture, and mechanical stress. FEP Non-Toxic Heat Shrink Tubing excels in these environments due to its high durability and tear resistance. It shields components from physical damage caused by vibration and impact, ensuring uninterrupted performance. Furthermore, its UV resistance makes it suitable for outdoor applications, such as protecting wiring in vehicles exposed to sunlight. This durability reduces maintenance needs, offering long-term cost savings for manufacturers and vehicle owners alike.

Aerospace Industry

Insulating Critical Systems

In the aerospace sector, safety and reliability are paramount. FEP Non-Toxic Heat Shrink Tubing plays a vital role in insulating critical systems, such as avionics and communication equipment. Its superior dielectric properties ensure stable electrical performance, even under high-voltage conditions. The tubing's lightweight nature minimizes the overall weight of aircraft systems, contributing to fuel efficiency. Additionally, its resistance to extreme temperatures and radiation ensures that it maintains integrity during high-altitude flights. These features make it an indispensable component in modern aerospace engineering.

Meeting Stringent Safety Standards

Aerospace applications demand materials that meet rigorous safety and performance standards. FEP Non-Toxic Heat Shrink Tubing complies with these requirements due to its non-toxic composition and exceptional thermal stability. It resists degradation when exposed to harsh chemicals, ensuring long-term reliability in fuel systems and hydraulic lines. The tubing's ability to maintain performance in extreme conditions aligns with the stringent regulations governing aerospace operations. By incorporating this tubing, manufacturers enhance the safety and efficiency of their systems, fostering trust in high-stakes environments.

Medical Industry

Ensuring Biocompatibility

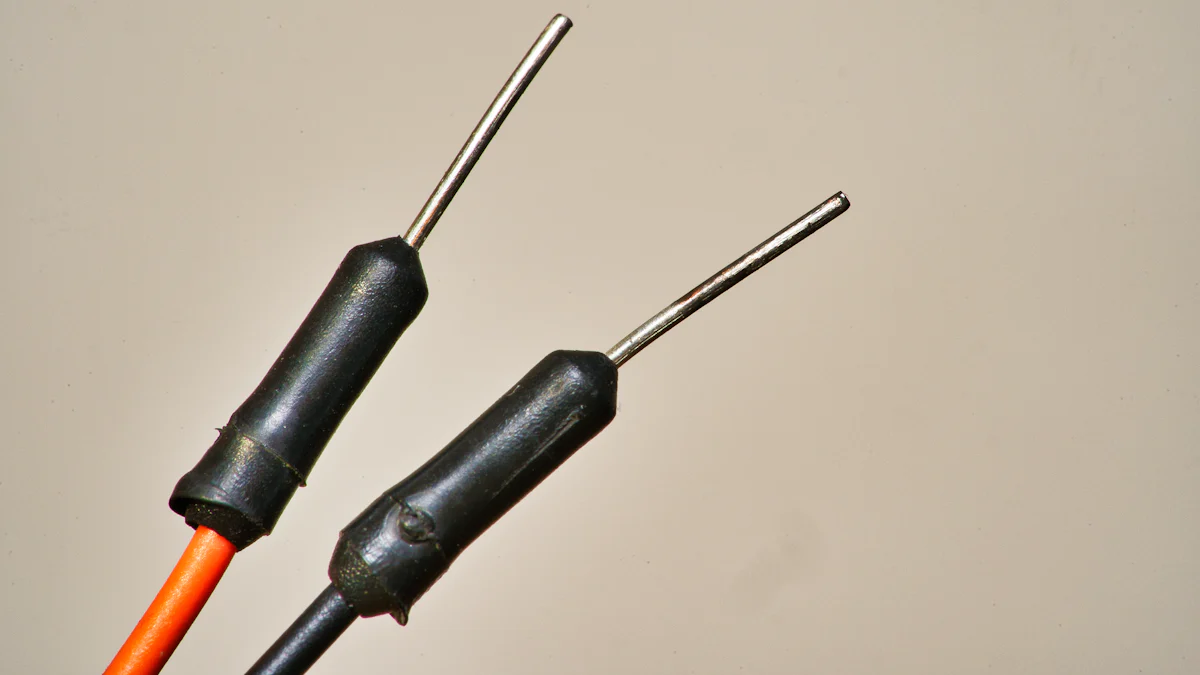

The medical industry prioritizes patient safety and product reliability, making FEP Non-Toxic Heat Shrink Tubing an ideal choice for various applications. Its biocompatibility ensures that it does not cause adverse reactions when used in medical devices, such as catheters and surgical instruments. The tubing's chemical inertness prevents contamination, maintaining the purity of fluids and medications. Its clarity allows for easy monitoring of fluid flow, enhancing precision in critical procedures. These properties make it a trusted material in healthcare settings where safety and accuracy are essential.

Sterilization and Hygiene Benefits

Medical environments require materials that can withstand rigorous sterilization processes. FEP Non-Toxic Heat Shrink Tubing meets this need with its resistance to high temperatures and harsh cleaning agents. It maintains its structural integrity during autoclaving and other sterilization methods, ensuring consistent performance. The tubing's non-stick surface simplifies cleaning, reducing the risk of residue buildup and contamination. These hygiene benefits make it suitable for use in surgical tools, diagnostic equipment, and fluid transfer systems. By supporting stringent cleanliness standards, this tubing contributes to improved patient outcomes and operational efficiency.

Chemical Processing Industry

Resistance to Corrosive Chemicals

FEP Non-Toxic Heat Shrink Tubing demonstrates exceptional resistance to corrosive chemicals, making it a reliable choice for chemical processing environments. Its chemical inertness ensures compatibility with a wide range of reactive substances, including acids, bases, and solvents. This property prevents degradation, even when exposed to aggressive chemicals over extended periods. Industries handling hazardous materials rely on this tubing to maintain the integrity of their systems and protect sensitive components from damage.

The tubing's ability to resist chemical reactions enhances safety in facilities where leaks or contamination could lead to catastrophic outcomes. For example, in fluid transfer systems, FEP tubing ensures that corrosive chemicals do not compromise the equipment. This reliability reduces downtime caused by maintenance or replacements, improving operational efficiency. By offering robust protection against chemical exposure, FEP tubing supports the seamless functioning of critical processes in chemical plants.

Maintaining Integrity in High-Temperature Environments

FEP Non-Toxic Heat Shrink Tubing excels in high-temperature environments, maintaining its structural integrity under extreme heat. Its thermal stability allows it to perform consistently in processes involving elevated temperatures, such as distillation, refining, and polymer production. Unlike conventional materials, FEP tubing resists melting or deformation, ensuring uninterrupted operation in demanding conditions.

Chemical processing industries benefit from the tubing's ability to withstand temperature fluctuations without compromising performance. For instance, during autoclaving or cleaning procedures, FEP tubing retains its durability and functionality. Its resistance to thermal stress minimizes the risk of system failures, enhancing the safety and reliability of industrial operations. This capability makes it an indispensable component in applications requiring both heat resistance and chemical compatibility.

Electronics and Electrical Applications

Insulating and Protecting Sensitive Components

FEP Non-Toxic Heat Shrink Tubing provides superior insulation for sensitive electronic components, ensuring reliable performance in critical systems. Its dielectric properties prevent electrical interference, safeguarding circuits from short circuits and voltage fluctuations. This feature is particularly valuable in industries like telecommunications, aerospace, and consumer electronics, where precision and stability are essential.

The tubing also protects components from environmental factors, such as moisture, dust, and UV radiation. Its non-stick surface simplifies installation, allowing technicians to apply it seamlessly over delicate parts. In laboratory settings, FEP tubing supports accurate and reliable results by insulating equipment used for chromatography, gas analysis, and fluid handling. These qualities make it a trusted solution for protecting sensitive electronics in diverse applications.

Preventing Short Circuits and Failures

FEP Non-Toxic Heat Shrink Tubing plays a crucial role in preventing short circuits and electrical failures. Its high resistance to voltage breakdown ensures that electrical systems remain operational, even under high-stress conditions. This reliability reduces the risk of costly downtime and equipment damage, making it a preferred choice for industries requiring consistent performance.

The tubing's low gas permeability further enhances its protective capabilities by preventing moisture ingress, which can lead to corrosion or electrical malfunctions. Additionally, its ability to withstand extreme temperatures ensures that it performs effectively in both high-heat and sub-zero environments. By minimizing the likelihood of electrical failures, FEP tubing supports the longevity and efficiency of electronic systems across various industries.

"FEP tubing's dielectric strength and thermal stability make it indispensable for insulating and protecting sensitive components in demanding environments," as noted by industry experts.

How FEP Non-Toxic Heat Shrink Tubing Addresses Industry Challenges

Overcoming Safety Concerns in Sensitive Applications

FEP Non-Toxic Heat Shrink Tubing effectively addresses safety concerns in industries where contamination or exposure to harmful substances poses significant risks. Its non-toxic composition ensures that no hazardous chemicals leach into sensitive environments, making it a reliable choice for medical, food processing, and pharmaceutical applications. For instance, in healthcare, the tubing supports patient safety by maintaining biocompatibility and preventing contamination during critical procedures.

The tubing's chemical inertness further enhances its safety profile. It remains unaffected by aggressive substances, ensuring that corrosive chemicals do not compromise the integrity of systems. This feature proves invaluable in chemical processing plants, where the safe transfer of reactive substances is essential. Additionally, its non-stick surface simplifies cleaning, reducing the risk of residue buildup and contamination in food and beverage handling. These properties make FEP tubing a trusted solution for industries prioritizing safety and hygiene.

"The increasing emphasis on patient safety and efficacy in healthcare is boosting the demand for high-quality medical components like FEP heat shrink tubing," as noted by industry experts.

Ensuring Reliability in Harsh and Demanding Environments

FEP Non-Toxic Heat Shrink Tubing demonstrates exceptional reliability in challenging industrial conditions. Its ability to withstand extreme temperatures ensures consistent performance in both high-heat and sub-zero environments. This makes it indispensable for sectors such as aerospace, automotive, and chemical processing, where equipment often operates under harsh conditions.

The tubing's chemical resistance enhances its durability in environments exposed to corrosive substances. For example, in chemical processing plants, it prevents leaks and contamination during the transportation of aggressive chemicals. Its low gas permeability ensures airtight seals, further improving system reliability. Additionally, the tubing resists UV radiation and moisture, maintaining its structural integrity in outdoor applications. These features enable industries to rely on FEP tubing for long-term performance in demanding settings.

The automotive sector benefits significantly from the tubing's robust construction. It protects wiring and components from mechanical stress, vibration, and impact, ensuring uninterrupted operation. Similarly, in aerospace, the tubing insulates critical systems, safeguarding them from voltage fluctuations and environmental factors. By delivering consistent performance, FEP tubing supports the seamless functioning of industrial systems across diverse applications.

Supporting Sustainable and Eco-Friendly Practices

FEP Non-Toxic Heat Shrink Tubing contributes to sustainability by promoting energy efficiency and reducing waste. Its superior insulating properties minimize energy loss in electrical systems, lowering operational costs and supporting eco-friendly practices. Industries can rely on this tubing to enhance the efficiency of high-voltage applications while maintaining consistent performance.

The tubing's durability further aligns with sustainability goals. Its high resistance to tearing and impact reduces the frequency of replacements, minimizing waste and resource consumption. For example, in the automotive industry, the tubing extends the lifespan of wiring and components, reducing maintenance needs and associated costs. Additionally, its non-stick surface simplifies cleaning, saving water and cleaning agents in food processing and medical applications.

FEP tubing also supports hygienic practices in industries requiring strict cleanliness standards. Its easy-to-clean surface ensures that food and beverage products remain uncontaminated during transportation. This feature enhances food safety while reducing the environmental impact of cleaning processes. By integrating FEP tubing into their operations, industries can achieve sustainability without compromising performance or safety.

"FEP tubing is vital in ensuring food safety by providing an ideal transportation medium for beverages, dairy products, sauces, and other food items requiring hygienic handling," according to industry insights.

Why FEP Non-Toxic Heat Shrink Tubing is a Game-Changer

Transforming Industrial Processes with Advanced Features

FEP Non-Toxic Heat Shrink Tubing has redefined industrial processes by offering advanced features that surpass traditional materials. Its chemical resistance ensures compatibility with harsh substances, making it indispensable in environments like chemical processing plants. Unlike conventional materials, FEP tubing maintains its integrity under extreme conditions, including high temperatures and exposure to corrosive chemicals. This reliability reduces downtime and enhances operational efficiency.

The tubing's transparency allows for fluid flow observation, a feature that traditional materials often lack. Industries benefit from this clarity, especially in medical and laboratory applications where precision is critical. Additionally, its low gas permeability ensures airtight seals, preventing leaks in sensitive systems. These properties make FEP tubing a superior alternative to PTFE and other fluoropolymer tubing, particularly in applications requiring tighter tolerances and higher working pressures.

"FEP tubing's ability to withstand extreme conditions while maintaining transparency and chemical resistance has revolutionized its use in industrial settings," according to industry experts.

Setting New Standards for Safety and Performance

FEP Non-Toxic Heat Shrink Tubing has set a new benchmark for safety and performance across industries. Its non-toxic composition ensures that no harmful substances leach into sensitive environments, making it ideal for medical, food processing, and pharmaceutical applications. This safety feature aligns with stringent regulatory standards, fostering trust in high-stakes environments.

The tubing's exceptional dielectric properties enhance electrical insulation, ensuring reliable performance in high-voltage applications. Its thermal stability allows it to function effectively in both high-heat and sub-zero conditions, outperforming traditional materials. Furthermore, its resistance to UV radiation and moisture ensures long-term durability in outdoor applications. These qualities have established FEP tubing as a trusted solution for industries prioritizing safety and reliability.

Driving Innovation Across Multiple Sectors

FEP Non-Toxic Heat Shrink Tubing has driven innovation across diverse sectors by addressing unique industrial challenges. In the automotive industry, it protects wiring and components from mechanical stress and chemical exposure, enhancing vehicle reliability. Aerospace manufacturers rely on its lightweight and durable properties to insulate critical systems, improving fuel efficiency and safety.

The medical sector benefits from its biocompatibility and sterilizability, which support the development of advanced medical devices. Chemical processing plants utilize its chemical inertness to handle reactive substances safely, reducing the risk of contamination or system failure. Its versatility extends to electronics, where it insulates sensitive components and prevents short circuits.

"FEP tubing's adaptability and advanced features have made it a cornerstone in industries ranging from aerospace to healthcare," as noted by professionals.

By integrating FEP Non-Toxic Heat Shrink Tubing into their operations, industries can achieve greater efficiency, safety, and sustainability. Its transformative impact underscores its role as a game-changer in modern industrial applications.

Choosing the Right FEP Non-Toxic Heat Shrink Tubing

Key Factors to Consider (Size, Temperature Range, Application)

Selecting the appropriate FEP Non-Toxic Heat Shrink Tubing requires careful evaluation of key factors to ensure optimal performance. The tubing's size must align with the dimensions of the components it will cover. A snug fit ensures proper insulation and protection, while an incorrect size may compromise functionality. Measuring the diameter of the target component and accounting for the tubing's shrink ratio is essential.

Temperature range is another critical consideration. FEP tubing offers exceptional thermal stability, making it suitable for applications involving extreme heat or sub-zero conditions. Industries should assess the operating environment to confirm that the tubing can withstand the required temperature range without degradation. For instance, chemical processing plants often rely on FEP tubing for its ability to endure high-temperature processes.

Application-specific requirements also play a significant role. Industries such as medical, aerospace, and electronics demand tubing with unique properties like chemical resistance, dielectric strength, or biocompatibility. For example, laboratories benefit from FEP tubing's transparency, which allows for fluid flow observation in chromatography systems and analytical instruments. Identifying the specific needs of the application ensures that the chosen tubing meets performance expectations.

Best Practices for Installation and Maintenance

Proper installation and maintenance maximize the lifespan and efficiency of FEP Non-Toxic Heat Shrink Tubing. During installation, technicians should ensure that the tubing is clean and free from contaminants. Dirt or debris can interfere with the tubing's adhesion and insulation properties. Using heat evenly during the shrinking process prevents uneven coverage or damage to the tubing.

Maintenance involves regular inspections to identify signs of wear, such as tears or discoloration. Although FEP tubing is highly durable, harsh environments may cause gradual degradation. Replacing damaged tubing promptly prevents potential system failures. Cleaning the tubing with appropriate solutions maintains its non-stick surface and ensures hygiene in sensitive applications like food processing or medical devices.

For industries requiring sterilization, such as healthcare, FEP tubing withstands autoclaving and other rigorous cleaning methods. Its resistance to high temperatures and chemicals ensures consistent performance even after repeated sterilization cycles. Following these best practices enhances the reliability and longevity of the tubing in demanding environments.

Partnering with Trusted Suppliers for Quality Assurance

Collaborating with reputable suppliers guarantees access to high-quality FEP Non-Toxic Heat Shrink Tubing. Trusted suppliers provide detailed product specifications, ensuring that the tubing meets industry standards and application requirements. They also offer a variety of options, including different sizes, colors, and shrink ratios, to accommodate diverse industrial needs.

Suppliers with expertise in fluoropolymer materials, such as FEP, often maintain strict quality control measures. This ensures that the tubing delivers consistent performance, even in critical applications. For example, black FEP tubing, designed for light-sensitive environments, undergoes rigorous testing to confirm its suitability for enzymatic and chemiluminescent reactions.

Additionally, reliable suppliers offer technical support and guidance during the selection and installation process. Their expertise helps industries make informed decisions, reducing the risk of errors or inefficiencies. Partnering with a trusted supplier not only ensures product quality but also fosters long-term success in industrial operations.

"Choosing the right supplier is as important as selecting the right material. A dependable supplier ensures that industries receive tubing tailored to their specific needs, enhancing both safety and performance," according to industry professionals.

FEP Non-Toxic Heat Shrink Tubing has redefined industrial standards by delivering unmatched safety, durability, and adaptability. Its ability to withstand extreme temperatures and resist harsh chemicals ensures reliable performance in critical sectors such as automotive, aerospace, medical, and chemical processing. By integrating this tubing, industries can enhance operational safety, streamline processes, and reduce environmental impact. Its transparency, chemical resistance, and thermal stability make it a cornerstone for sustainable and efficient practices. Adopting this innovative solution empowers industries to achieve long-term cost savings while maintaining superior performance.

FAQ

What is FEP tubing made of?

FEP tubing consists of fluorinated ethylene-propylene, a type of fluoropolymer. This material was developed as a melt-processable alternative to PTFE (polytetrafluoroethylene). Its unique composition provides excellent chemical resistance, thermal stability, and non-toxic properties, making it suitable for various industrial applications.

How does FEP tubing compare to PTFE tubing?

FEP tubing shares many properties with PTFE tubing, such as chemical inertness and high-temperature resistance. However, FEP tubing has a lower maximum operating temperature of +200°C compared to PTFE. The primary advantage of FEP tubing lies in its ease of processing. It can be cut and formed more easily, making it a practical choice for applications requiring precision and flexibility.

What are the common applications of FEP tubing?

FEP tubing serves a wide range of industries due to its versatility. It is commonly used in biopharmaceutical and laboratory settings for fluid transfer and chemical handling. Its chemical resistance and ability to withstand large temperature variations make it ideal for low-pressure applications. Additionally, industries like medical, aerospace, and electronics rely on FEP tubing for its insulating and protective properties.

Is FEP tubing safe for medical and food applications?

Yes, FEP tubing is non-toxic and chemically inert, ensuring safety in sensitive environments. Its biocompatibility makes it suitable for medical devices, such as catheters and surgical instruments. In food processing, it prevents contamination by resisting chemical reactions and maintaining hygiene standards. These features align with stringent regulatory requirements for safety and cleanliness.

Can FEP tubing withstand extreme temperatures?

FEP tubing performs reliably across a broad temperature range, from sub-zero conditions to a maximum of +200°C. Its thermal stability ensures consistent performance in high-heat environments, such as chemical processing plants and automotive systems. This capability makes it a dependable choice for industries requiring materials that endure extreme conditions.

How does FEP tubing contribute to energy efficiency?

FEP tubing enhances energy efficiency through its superior dielectric properties. It minimizes energy loss in electrical systems, ensuring optimal performance in high-voltage applications. Its insulating capabilities reduce power dissipation, which lowers operational costs and supports sustainable practices. Industries benefit from its ability to maintain consistent insulation even under demanding conditions.

What makes FEP tubing durable?

FEP tubing exhibits high resistance to tearing, impact, and chemical degradation. Its robust construction protects sensitive components from damage, extending the lifespan of critical systems. This durability reduces the need for frequent replacements, offering long-term cost savings for industries like aerospace, automotive, and electronics.

Can FEP tubing be sterilized?

Yes, FEP tubing withstands rigorous sterilization processes, including autoclaving and exposure to harsh cleaning agents. Its resistance to high temperatures and chemicals ensures that it maintains structural integrity during repeated sterilization cycles. This feature makes it ideal for medical and laboratory applications requiring strict hygiene standards.

How does FEP tubing ensure safety in industrial applications?

FEP tubing ensures safety through its non-toxic composition and chemical inertness. It prevents harmful substances from leaching into sensitive environments, making it suitable for medical, pharmaceutical, and food processing industries. Its resistance to corrosive chemicals and UV radiation further enhances safety in demanding industrial settings.

What factors should industries consider when selecting FEP tubing?

Industries should evaluate several factors when choosing FEP tubing. These include the size and shrink ratio to ensure a proper fit, the operating temperature range, and the specific application requirements. For example, laboratories may prioritize transparency for fluid monitoring, while chemical plants may focus on chemical resistance. Partnering with trusted suppliers ensures access to high-quality tubing tailored to unique industrial needs.

See Also

The Importance of Ultra-Thin PET Tubing in Healthcare

Etched PTFE: Revolutionizing Catheter Production Techniques

The Impact of Medical Grade PTFE Liners on Healthcare