Understanding FEP Non-Toxic Heat Shrink Tubing for Industrial Use

FEP non-toxic heat shrink tubing is a specialized material designed to provide insulation, protection, and durability in demanding industrial environments. Made from fluorinated ethylene propylene, this tubing offers exceptional chemical resistance, thermal stability, and biocompatibility. Its unique properties make it indispensable for industries requiring safe and reliable solutions. You can rely on this heat shrink tubing to safeguard sensitive components, ensuring optimal performance and longevity. Its non-toxic nature further enhances its suitability for applications where safety and compliance are critical. By using heat-shrinkable tubing, you achieve both efficiency and reliability in your operations.

Key Properties and Benefits of FEP Non-Toxic Heat Shrink Tubing

Chemical Resistance and Stability

FEP non-toxic heat shrink tubing stands out for its exceptional chemical resistance. This high-performance fluoropolymer resists a wide range of chemicals, including acids, bases, and solvents. You can rely on it to maintain its integrity even in environments exposed to harsh substances. Its inert nature ensures that it does not react with other materials, making it ideal for applications requiring stability and reliability.

The tubing also offers advanced gas and vapor permeability properties. This feature enhances its performance in industries where exposure to volatile compounds is common. Whether you work in chemical processing or electronics, this tubing provides unmatched protection for sensitive components. Its ability to withstand chemical spillage ensures long-term durability and safety in demanding industrial settings.

Temperature Resistance and Thermal Stability

FEP heat shrink tubing excels in temperature resistance, making it suitable for extreme thermal conditions. It can endure both high and low temperatures without losing its structural integrity. This thermal stability ensures consistent performance, even in environments with fluctuating temperatures.

The tubing’s lower shrink temperature compared to other materials, such as thin-wall PTFE tubing, allows for easier application. You can safely use it on temperature-sensitive materials without causing damage. This versatility makes it a preferred choice for industries like aerospace, automotive, and medical devices, where precision and reliability are critical.

Non-Toxicity and Biocompatibility

The non-toxic nature of FEP heat shrink tubing makes it a safe option for applications requiring strict compliance with health and safety standards. Its biocompatibility ensures that it can be used in medical devices, such as catheters, without posing risks to human health. You can trust this tubing to meet the rigorous demands of the medical and pharmaceutical industries.

Its non-toxic properties also make it suitable for food and beverage applications. The tubing ensures that no harmful substances leach into consumables, maintaining product safety and quality. By choosing FEP heat shrink tubing, you prioritize safety and compliance in every application.

Durability and Longevity in Industrial Environments

FEP non-toxic heat shrink tubing delivers exceptional durability, making it a reliable choice for demanding industrial environments. Its robust construction resists wear and tear, ensuring that it maintains its performance over extended periods. You can depend on this tubing to withstand mechanical stress, abrasion, and environmental factors without compromising its integrity.

The material's high chemical resistance further enhances its longevity. It remains unaffected by exposure to corrosive substances, such as acids or solvents, which are common in industrial settings. This resistance ensures that the tubing retains its protective properties, even in harsh conditions. By choosing FEP tubing, you reduce the need for frequent replacements, saving both time and resources.

FEP tubing also performs well under fluctuating temperatures. It maintains its strength and flexibility in extreme heat or cold, ensuring consistent protection for your components. This resilience makes it suitable for industries like aerospace, automotive, and electronics, where reliability is critical. Its ability to endure challenging environments ensures long-term value and peace of mind.

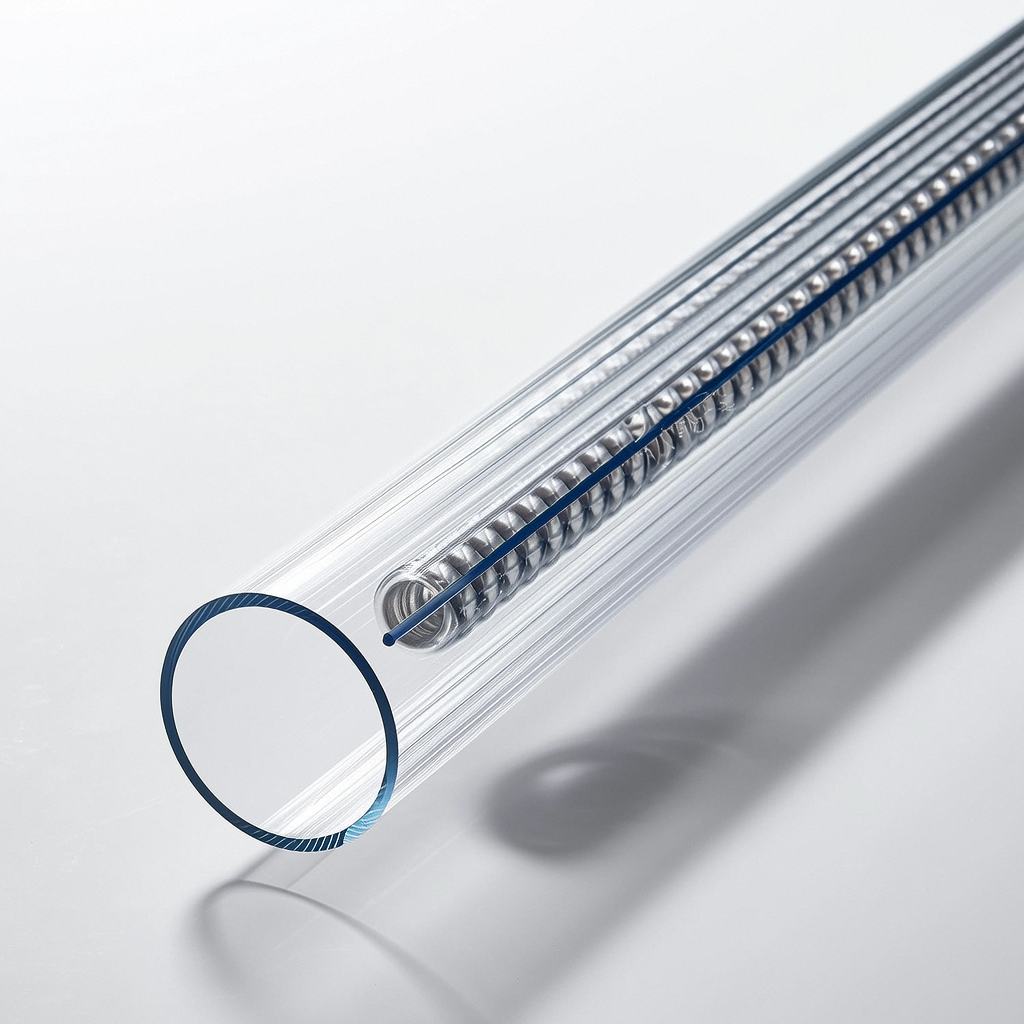

Transparency and Aesthetic Versatility

FEP heat shrink tubing stands out for its optical clarity. Its transparent nature allows you to visually inspect the components it covers, ensuring proper installation and functionality. This feature proves especially useful in applications requiring precision, such as medical devices and electronics. You can easily monitor the condition of your components without removing the tubing.

The aesthetic versatility of FEP tubing adds another layer of value. Its smooth, non-stick surface provides a clean and polished appearance, enhancing the overall presentation of your products. This quality makes it an excellent choice for industries where visual appeal matters, such as consumer electronics or high-end manufacturing.

Additionally, the transparency of FEP tubing does not compromise its performance. It retains all the essential properties, including chemical resistance, thermal stability, and durability. This combination of functionality and aesthetics ensures that you achieve both practical and visual benefits in your applications. By selecting FEP tubing, you prioritize both performance and design excellence.

Industrial Applications of FEP Heat Shrink Tubing

Electronics and Electrical Insulation

FEP heat shrink tubing plays a critical role in electronics and electrical systems. Its excellent insulating properties protect wires, cables, and sensitive components from electrical interference and environmental damage. You can use this tubing to ensure reliable performance in high-voltage applications, where safety and precision are essential.

The tubing’s chemical resistance and thermal stability make it ideal for environments exposed to harsh conditions. It withstands exposure to solvents, oils, and other corrosive substances commonly found in industrial settings. Its ability to maintain integrity under extreme temperatures ensures consistent protection for your electrical systems.

Additionally, the transparency of FEP tubing allows you to inspect connections and components without removing the tubing. This feature simplifies maintenance and ensures that your systems remain operational with minimal downtime. By choosing FEP heat shrink tubing, you enhance the durability and efficiency of your electrical insulation solutions.

Medical Devices and Pharmaceutical Applications

FEP heat shrink tubing is indispensable in the medical and pharmaceutical industries. Its non-toxic and biocompatible properties make it suitable for applications requiring the highest safety standards. You can rely on this tubing for use in catheters, surgical instruments, and other medical devices where patient safety is paramount.

The tubing’s high purity and chemical inertness ensure that it does not react with medications or biological materials. This makes it ideal for pharmaceutical manufacturing and biotechnology processes. Its flexibility and clarity further enhance its usability in these fields, allowing for precise applications and visual monitoring.

When processed under cleanroom conditions, FEP tubing meets the stringent requirements of in-vitro applications. For example, it is commonly used in cardiac catheters and other diagnostic tools. Its ability to maintain hygiene and product integrity ensures that you meet regulatory compliance while delivering reliable medical solutions.

Automotive and Aerospace Components

In automotive and aerospace industries, FEP heat shrink tubing provides unmatched performance and reliability. Its resistance to fuels, hydraulic fluids, and other chemicals makes it an excellent choice for fuel lines and fluid transfer systems. You can depend on this tubing to maintain its integrity even under the most demanding conditions.

The tubing’s thermal stability allows it to endure extreme temperature variations, which are common in aerospace operations. It performs consistently in both high-altitude environments and ground-level applications. This resilience ensures that your components remain protected and functional throughout their lifecycle.

FEP tubing also offers an effective environmental seal, safeguarding components from moisture, dust, and other contaminants. This feature enhances the longevity of automotive and aerospace systems, reducing the need for frequent maintenance. By incorporating FEP heat shrink tubing into your designs, you achieve superior performance and reliability in critical applications.

Food and Beverage Industry Compliance

FEP heat shrink tubing plays a vital role in the food and beverage industry, where maintaining hygiene and product integrity is essential. Its inert and non-reactive nature ensures that it does not impart any taste, odor, or contaminants to the products it comes into contact with. This makes it an ideal choice for applications such as beverage dispensing systems, food processing equipment, and dairy operations.

The tubing’s high chemical resistance and non-stick surface simplify cleaning processes, reducing the risk of contamination. You can rely on it to handle liquids and gases efficiently, even in environments requiring strict regulatory compliance. Its ability to withstand extreme temperatures further enhances its suitability for food-grade applications, ensuring consistent performance in both hot and cold conditions.

FEP heat shrink tubing also meets the rigorous standards of food safety regulations. Its transparency allows you to monitor the flow of liquids or gases, ensuring smooth operations and quick identification of any issues. By incorporating this tubing into your food and beverage systems, you prioritize safety, efficiency, and quality in every step of your process.

Specialized Industrial Use Cases

FEP heat shrink tubing offers unmatched versatility, making it indispensable in specialized industrial applications. Its superior chemical resistance and thermal stability make it a reliable choice for industries such as chemical processing, semiconductor manufacturing, and environmental monitoring. You can use it in processes involving highly corrosive substances or extreme temperatures without compromising performance.

In laboratories, FEP tubing proves invaluable for critical applications like chromatography and auto-sampling. Its high purity and inertness ensure accurate results by preventing contamination or interference. Additionally, its flexibility and compatibility with various fittings make installation straightforward, saving you time and effort.

The aerospace and automotive industries also benefit from FEP heat shrink tubing. Its ability to resist fuels, hydraulic fluids, and other harsh chemicals ensures the longevity of components in demanding environments. You can depend on it to provide reliable insulation and protection for wiring, fluid transfer systems, and other critical parts.

FEP tubing’s adaptability extends to emerging technologies and niche applications. From insulating high-temperature cables to serving as a protective layer in advanced manufacturing processes, it continues to meet the evolving needs of modern industries. By choosing FEP heat shrink tubing, you gain a versatile solution that delivers consistent performance across a wide range of specialized use cases.

Comparison of FEP Tubing with Other Heat Shrink Products

FEP vs. PTFE: Key Differences and Use Cases

When comparing FEP tubing to PTFE heat shrink tubes, you notice several key differences that influence their applications. FEP tubing offers greater flexibility and transparency, making it ideal for situations where visual inspection or adaptability is essential. Its optical clarity allows you to monitor components without removing the tubing, which proves valuable in industries like medical devices and electronics.

FEP tubing also has a lower shrink temperature than PTFE heat shrink tubes. This feature simplifies installation and reduces the risk of damaging temperature-sensitive materials. You can use FEP tubing in applications requiring precision and ease of use, such as aerospace and automotive systems.

On the other hand, PTFE heat shrink tubes excel in extreme temperature resistance. They can withstand higher operating temperatures compared to FEP tubing, making them suitable for environments exposed to intense heat. However, PTFE heat shrink tubes lack the flexibility and transparency that FEP tubing provides. If your application demands a balance of chemical resistance, flexibility, and optical clarity, FEP tubing becomes the superior choice.

FEP vs. PVC: Advantages and Limitations

FEP tubing and PVC heat shrink tubing serve different purposes due to their distinct properties. FEP tubing offers exceptional chemical resistance, making it suitable for harsh industrial environments. It resists acids, bases, and solvents, ensuring long-term durability. PVC tubing, while more affordable, lacks the same level of chemical resistance and may degrade when exposed to corrosive substances.

FEP tubing also outperforms PVC in temperature resistance. It can handle temperatures up to 200°C, whereas PVC tubing has a much lower thermal threshold. This makes FEP tubing a better option for high-temperature applications, such as in aerospace or automotive industries.

However, PVC tubing has its advantages. It is more cost-effective and easier to source for general-purpose applications. If your project involves less demanding conditions, PVC tubing might suffice. But for critical applications requiring reliability, chemical resistance, and thermal stability, FEP tubing remains the better investment.

Why Choose FEP for Industrial Applications?

FEP tubing stands out as a versatile and reliable solution for industrial use. Its unique combination of properties—chemical resistance, thermal stability, and flexibility—ensures consistent performance in demanding environments. You can rely on FEP tubing to protect sensitive components from harsh chemicals, extreme temperatures, and mechanical stress.

Unlike PTFE heat shrink tubes, FEP tubing offers a lower shrink temperature and greater transparency. These features simplify installation and allow for visual inspection, saving you time and effort during maintenance. Compared to PVC tubing, FEP tubing delivers superior durability and resistance to environmental factors, making it a long-term solution for critical applications.

Industries such as aerospace, medical devices, and food processing benefit significantly from FEP tubing. Its non-toxic nature ensures compliance with safety standards, while its adaptability meets the specific needs of various sectors. By choosing FEP tubing, you prioritize efficiency, reliability, and safety in your operations.

Practical Guidance for Selecting and Using FEP Heat Shrink Tubing

Choosing the Right Size, Thickness, and Shrink Ratio

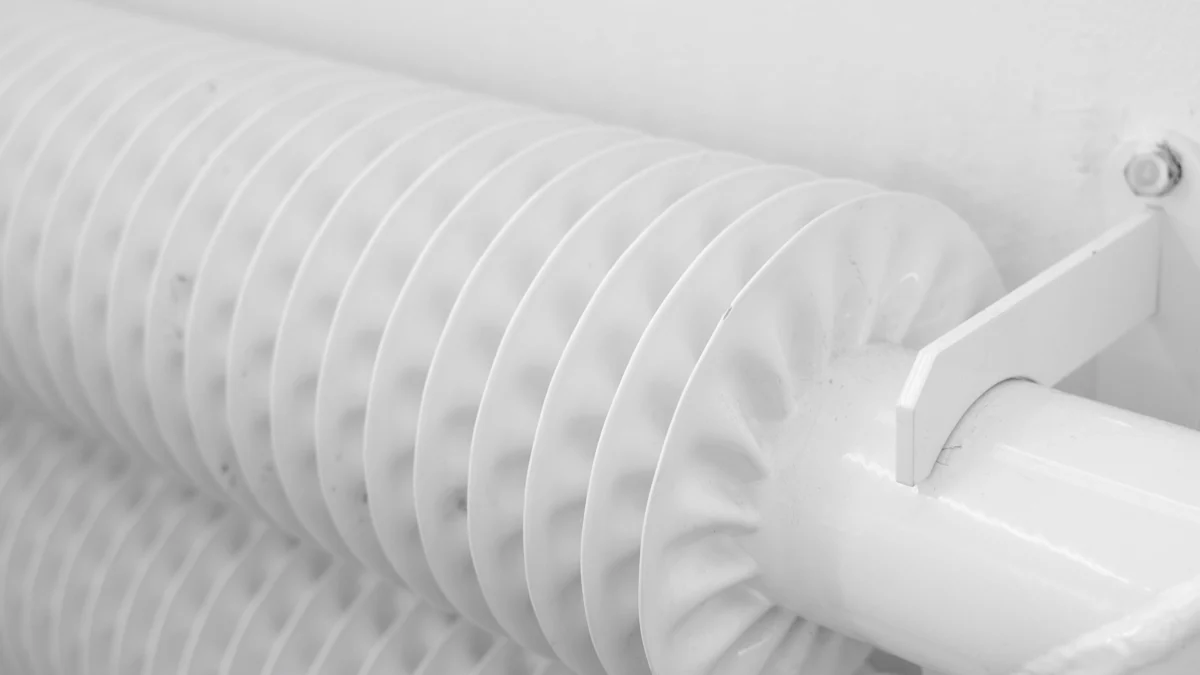

Selecting the correct size, thickness, and shrink ratio is essential to ensure optimal performance of FEP heat shrink tubing. Begin by measuring the diameter of the component you want to cover. The tubing should have an initial diameter slightly larger than the component but shrink tightly around it when heated. This ensures a secure fit without gaps or loose ends.

Thickness plays a critical role in determining the level of protection. Thicker tubing provides enhanced durability and resistance to mechanical stress, making it suitable for demanding industrial environments. However, thinner tubing offers greater flexibility and is ideal for applications requiring precision, such as medical devices or electronics.

The shrink ratio indicates how much the tubing will reduce in size when heated. Common ratios include 2:1 and 3:1. A higher shrink ratio accommodates components with irregular shapes or varying diameters. For example, if you are working with connectors or joints, a 3:1 ratio ensures a snug fit across all sections. By carefully evaluating these factors, you can make informed decisions when choosing the right heat shrink product for your specific needs.

Installation Techniques and Best Practices

Proper installation ensures the effectiveness and longevity of FEP heat shrink tubing. Start by cleaning the component to remove any dirt, grease, or contaminants. This step prevents interference with the tubing’s adhesion and ensures a smooth application. Cut the tubing to the desired length, leaving a small margin to account for shrinkage during heating.

When applying the tubing, use a heat gun or other controlled heat source. Avoid open flames, as they can damage the tubing or the underlying component. Hold the heat source at a consistent distance and move it evenly around the tubing. This ensures uniform shrinkage and prevents overheating in specific areas. Monitor the process closely to achieve a tight and secure fit.

For temperature-sensitive materials, FEP tubing offers a significant advantage due to its lower shrink temperature. You can safely apply it without risking damage to delicate components. After installation, inspect the tubing for any gaps or uneven sections. Addressing these issues immediately ensures reliable performance and protection.

Customization Options for Industry-Specific Needs

FEP heat shrink tubing offers extensive customization options to meet the unique requirements of various industries. Manufacturers provide tubing in different sizes, colors, and wall thicknesses, allowing you to tailor the product to your application. For instance, transparent tubing is ideal for medical devices, where visual inspection is crucial. Colored tubing can help with identification and organization in complex wiring systems.

Specialized coatings or additives enhance the tubing’s properties for specific uses. For example, UV-resistant coatings improve performance in outdoor applications, while anti-static additives reduce the risk of electrical interference in sensitive electronics. Custom lengths and pre-cut pieces simplify installation and reduce waste, especially in high-volume operations.

You can also request tubing with specific shrink ratios or tolerances to accommodate unique components. These options ensure that the tubing fits perfectly and performs reliably, even in challenging conditions. By exploring customization possibilities, you can optimize the use of FEP heat shrink tubing for your industry’s demands.

Maintenance and Storage Tips for Longevity

Proper maintenance and storage of FEP heat shrink tubing ensure its long-term performance and reliability. By following a few straightforward practices, you can maximize the lifespan of your tubing and maintain its essential properties.

1. Keep Tubing Clean and Free from Contaminants

Dirt, grease, and other contaminants can compromise the performance of FEP tubing. Before use, inspect the tubing for any visible debris. Wipe it with a clean, lint-free cloth if necessary. Avoid exposing the tubing to harsh cleaning agents that may degrade its surface over time. Maintaining cleanliness ensures that the tubing retains its chemical resistance and durability.

2. Store in a Controlled Environment

Temperature and humidity play a significant role in preserving the quality of FEP tubing. Store it in a cool, dry place away from direct sunlight or heat sources. Excessive heat can cause premature shrinkage, while prolonged exposure to UV light may weaken its structural integrity. A controlled environment helps the tubing maintain its flexibility and thermal stability.

3. Avoid Prolonged Chemical Exposure

Although FEP tubing resists many chemicals, consistent exposure to aggressive substances can lead to gradual degradation. If your application involves contact with corrosive materials, inspect the tubing regularly for signs of wear or damage. Replace it promptly if you notice any cracks or discoloration. This proactive approach prevents potential failures and ensures safety.

“High purity FEP tubing is resistant to many chemicals, but consistent exposure can lead to degradation over time, posing challenges in durability for customers.”

4. Organize and Label Tubing Properly

Organized storage simplifies access and reduces the risk of damage. Use labeled containers or spools to separate different sizes, thicknesses, or shrink ratios. This practice prevents tangling and ensures that you select the correct tubing for each application. Proper organization also minimizes waste and saves time during installation.

5. Inspect Before Each Use

Before applying FEP tubing, examine it for any signs of damage, such as cuts, abrasions, or uneven surfaces. Damaged tubing may not provide adequate protection or insulation. Regular inspections help you identify issues early and maintain the reliability of your components.

6. Rotate Stock to Prevent Aging

Over time, even high-quality materials like FEP tubing can experience slight changes in properties. To avoid using older stock that may have degraded, implement a first-in, first-out (FIFO) system. This ensures that you always use the freshest tubing available, maintaining consistent performance across applications.

By adopting these maintenance and storage practices, you protect your investment in FEP heat shrink tubing. These steps not only extend its lifespan but also ensure that it continues to deliver reliable performance in demanding industrial environments.

FEP non-toxic heat shrink tubing offers unmatched benefits, including chemical resistance, thermal stability, and non-toxicity. These properties make it indispensable for industries like aerospace, medical devices, and food processing. By using FEP tubing, you enhance safety, efficiency, and reliability in your operations.

Emerging innovations, such as advanced coatings and tailored shrink ratios, continue to expand its applications. As industries evolve, FEP tubing remains a versatile and forward-thinking solution. By choosing this material, you stay ahead in meeting both current demands and future challenges with confidence.

FAQ

What is FEP Tubing?

FEP tubing is a specialized product made from fluorinated ethylene propylene (FEP). This material provides high purity and exceptional chemical resistance, making it ideal for demanding industrial applications. You can rely on FEP tubing for its durability and ability to withstand harsh environments.

How Does FEP Heat Shrink Tubing Work?

FEP heat shrink tubing works by shrinking tightly around components when exposed to heat. You apply the tubing over the desired part and use a heat source, such as a heat gun, to activate the shrinking process. The tubing conforms to the shape of the component, providing insulation, protection, and a secure fit.

What Are the Key Benefits of Using FEP Heat Shrink Tubing?

FEP heat shrink tubing offers several benefits, including:

Chemical Resistance: Protects against acids, bases, and solvents.

Thermal Stability: Performs well in extreme temperatures.

Non-Toxicity: Safe for medical and food-grade applications.

Durability: Resists wear, tear, and environmental stress.

Transparency: Allows visual inspection of covered components.

These features make it a versatile solution for various industries.

Can FEP Tubing Be Used in High-Temperature Applications?

Yes, FEP tubing performs exceptionally well in high-temperature environments. It can withstand temperatures up to 200°C without losing its structural integrity. This makes it suitable for industries like aerospace, automotive, and electronics, where thermal stability is critical.

Is FEP Tubing Safe for Medical and Food Applications?

FEP tubing is non-toxic and biocompatible, ensuring safety for medical and food-related uses. You can use it in medical devices, such as catheters, or in food processing equipment without worrying about harmful substances leaching into products. Its compliance with health and safety standards makes it a trusted choice in these industries.

How Do I Choose the Right Size and Shrink Ratio for My Application?

To select the correct size and shrink ratio, measure the diameter of the component you want to cover. Choose tubing with an initial diameter slightly larger than the component. For irregular shapes, opt for a higher shrink ratio, such as 3:1, to ensure a snug fit. Proper sizing ensures optimal performance and protection.

What Makes FEP Tubing Different from PTFE or PVC Tubing?

FEP tubing differs from PTFE and PVC tubing in several ways:

FEP vs. PTFE: FEP tubing offers greater flexibility and transparency, while PTFE tubing withstands higher temperatures.

FEP vs. PVC: FEP tubing provides superior chemical resistance and thermal stability, whereas PVC tubing is more cost-effective but less durable.

You should choose FEP tubing for applications requiring a balance of flexibility, durability, and chemical resistance.

How Should I Store FEP Heat Shrink Tubing?

Store FEP heat shrink tubing in a cool, dry place away from direct sunlight or heat sources. Keep it clean and free from contaminants to maintain its properties. Organize and label different sizes and shrink ratios to simplify access and prevent damage during storage.

Can FEP Tubing Be Customized for Specific Applications?

Yes, FEP tubing offers extensive customization options. You can select different sizes, colors, wall thicknesses, and shrink ratios to meet your specific needs. Manufacturers also provide specialized coatings, such as UV resistance or anti-static properties, to enhance performance in unique environments.

What Are Common Mistakes to Avoid During Installation?

Avoid these common mistakes when installing FEP heat shrink tubing:

Using an open flame as a heat source, which can damage the tubing.

Skipping the cleaning step, leading to poor adhesion.

Overheating the tubing, causing uneven shrinkage or damage.

Choosing the wrong size or shrink ratio, resulting in a loose or improper fit.

By following proper installation techniques, you ensure reliable performance and longevity.

See Also

The Importance of Ultra-Thin PET Tubing in Healthcare

New Developments in PTFE Liners for Medical Applications

Global Comparison of Etched PTFE Liner Manufacturers