FEP Heat Shrink Tubing Brands Compared for Temperature Resistance

FEP heat shrink tubing for temperature resistance plays a critical role in applications requiring exceptional performance. Its ability to withstand extreme conditions, ranging from -200°C to 200°C, makes it indispensable in industries like aerospace, automotive, and medical. Selecting the right brand ensures reliable performance under high-temperature stress. Beyond temperature resistance, factors such as durability, flexibility, and chemical resistance significantly influence the choice of a heat shrink product. These attributes ensure the tubing remains effective in harsh environments, providing long-term protection and functionality for sensitive components.

What Is FEP Heat Shrink Tubing and Why Is Temperature Resistance Important?

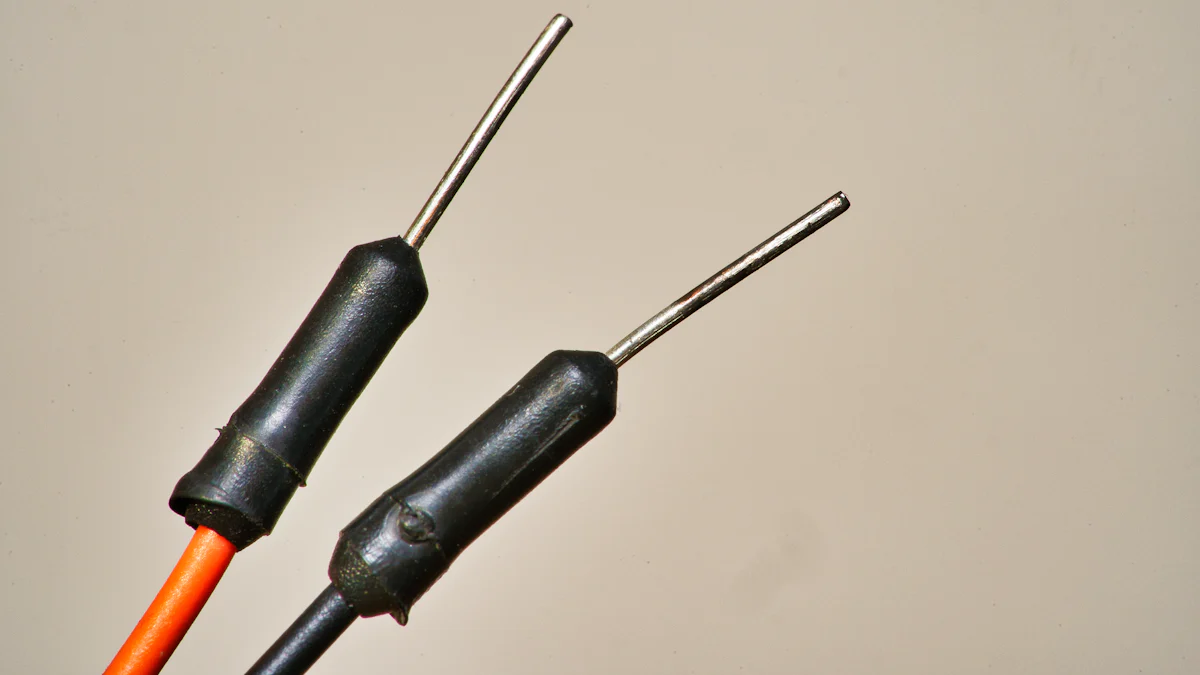

FEP heat shrink tubing is a specialized product designed to provide insulation, protection, and encapsulation for sensitive components. Made from fluorinated ethylene propylene (FEP), this tubing exhibits unique properties that make it indispensable in demanding environments. Its ability to withstand extreme temperatures, ranging from -200°C to 200°C, ensures reliable performance in both high-heat and sub-zero conditions. This exceptional temperature resistance makes it a preferred choice for industries requiring robust solutions for critical applications.

Key Features of FEP Heat Shrink Tubing

High-temperature performance and operating range (-200°C to 200°C)

FEP heat shrink tubing offers unparalleled high-temperature performance. It maintains structural integrity and functionality across a wide operating range, from -200°C to 200°C. This capability ensures that the tubing performs effectively in extreme environments, such as aerospace and automotive sectors. Unlike PTFE, FEP tubing requires a lower shrink temperature, approximately 420°F, which reduces the risk of damaging temperature-sensitive materials during installation. This feature enhances its versatility and usability in various applications.

Chemical and electrical resistance for demanding environments

The chemical resistance of FEP heat shrink tubing protects components from corrosive substances, including acids, bases, and solvents. This property ensures durability and longevity, even in harsh industrial settings. Additionally, its high dielectric strength provides excellent electrical insulation, safeguarding sensitive wiring and components from electrical hazards. These attributes make FEP tubing a reliable choice for applications requiring both chemical and electrical protection.

Common Applications of FEP Heat Shrink Tubing

Aerospace and automotive industries for wiring protection

In aerospace and automotive industries, FEP heat shrink tubing plays a crucial role in protecting wiring systems. It shields cables from high temperatures, UV exposure, and environmental stress. Its resistance to hydraulic fluids and fuel ensures long-term reliability in these demanding sectors. The tubing also provides insulation for electrical systems, enhancing safety and performance in vehicles and aircraft.

Medical and electronics sectors for sterilization and insulation

FEP heat shrink tubing is widely used in medical applications due to its biocompatibility and ability to withstand sterilization processes. It serves as a protective layer for catheters, endoscopes, and surgical instruments, ensuring safety and durability. In the electronics sector, the tubing provides insulation for sensitive components, protecting them from heat, moisture, and electrical interference. Its optical clarity and low friction further enhance its suitability for precision applications.

Comparing Temperature Resistance Across Top FEP Heat Shrink Tubing Brands

When selecting the best heat shrink tubing for demanding applications, understanding how top brands perform under extreme temperatures is essential. This section evaluates the temperature resistance and performance of three leading manufacturers: Zeus, 3M, and TE Connectivity. Each brand offers unique advantages, ensuring suitability for specific industries and applications.

Brand A: Zeus

Temperature resistance specifications (up to 200°C)

Zeus stands out for its advanced engineering in heat shrink tubing. Its products are designed to withstand temperatures up to 200°C, making them ideal for high-heat environments. The tubing maintains structural integrity and functionality even when exposed to prolonged thermal stress. This capability ensures reliable performance in critical applications.

Performance in high-temperature environments and UV resistance

Zeus heat shrink tubing excels in environments where heat, corrosion, and UV exposure pose significant challenges. The tubing provides a tight, protective covering that resists degradation from ultraviolet light. This feature makes it a preferred choice for outdoor applications, such as aerospace wiring systems and automotive harnesses. Additionally, Zeus products offer superior chemical resistance, ensuring durability in harsh industrial conditions.

Brand B: AccuPath

Temperature resistance specifications (up to 200°C)

AccuPath heat shrink tubing also supports a maximum operating temperature of 200°C. The brand’s focus on innovation ensures consistent performance across a wide range of applications. Its tubing is engineered to meet stringent industry standards, providing reliable insulation and protection under extreme conditions.

Performance in industrial and medical applications

AccuPath products are widely used in industrial and medical sectors due to their versatility and reliability. In industrial settings, the tubing protects sensitive components from heat, moisture, and electrical interference. For medical applications, AccuPath heat shrink tubing offers biocompatibility and sterilization compatibility, making it suitable for use in surgical instruments and medical devices. Its optical clarity and flexibility further enhance its usability in precision applications.

Brand C: TE Connectivity

Temperature resistance specifications (up to 200°C)

TE Connectivity heat shrink tubing matches the temperature resistance of Zeus and 3M, with a maximum operating range of 200°C. The brand’s products are designed to endure extreme thermal conditions without compromising performance. This makes them a dependable choice for industries requiring robust solutions.

Performance in aerospace and automotive sectors

TE Connectivity specializes in providing heat shrink tubing for aerospace and automotive applications. Its products protect wiring systems from high temperatures, hydraulic fluids, and environmental stress. The tubing also resists wear and tear caused by vibration and mechanical strain, ensuring long-term reliability. TE Connectivity’s focus on durability and precision makes it a trusted name in these demanding industries.

Summary Table of Temperature Resistance by Brand

The following table provides a concise comparison of the temperature resistance capabilities of the top FEP heat shrink tubing brands. This summary highlights their maximum operating temperatures and key performance attributes, offering a clear perspective for users seeking optimal solutions for high-temperature applications.

Brand | Maximum Operating Temperature | Key Performance Attributes |

|---|---|---|

Zeus | 200°C (392°F) | Exceptional UV resistance, reliable in prolonged thermal stress, and superior chemical durability. |

AccuPath | 200°C (392°F) | Versatile for industrial and medical applications, with biocompatibility and sterilization compatibility. |

TE Connectivity | 200°C (392°F) | Designed for aerospace and automotive sectors, with resistance to hydraulic fluids and mechanical strain. |

Note: All three brands maintain a consistent maximum operating temperature of 200°C (392°F), ensuring suitability for demanding environments. However, their unique attributes cater to specific industry needs.

Additional Insights on Temperature Resistance

FEP vs. PTFE: While FEP tubing operates effectively up to 200°C (392°F), PTFE offers a higher temperature resistance, reaching up to 340°C (644°F). This makes PTFE more suitable for extreme heat applications.

Comparison with PFA and PEEKshrink™: PFA and PEEKshrink™ surpass FEP in thermal resistance, with maximum operating temperatures of 260°C (500°F). These materials are ideal for applications requiring higher thermal stability.

Silicone Tubing: Although not directly comparable to FEP, silicone tubing provides excellent flexibility and chemical resistance, withstanding both high and low temperatures effectively.

This table and additional insights aim to guide users in selecting the most appropriate FEP heat shrink tubing brand based on their specific temperature resistance requirements and application needs.

Other Factors to Consider When Choosing FEP Heat Shrink Tubing

When selecting the right heat shrink tubing, evaluating additional factors beyond temperature resistance ensures optimal performance. These considerations, including durability, flexibility, and chemical resistance, play a critical role in determining the suitability of a product for specific applications.

Durability and Longevity

Resistance to wear and tear in harsh conditions

Durability remains a key attribute of any heat shrink product. In demanding environments, such as aerospace or industrial settings, tubing must withstand mechanical stress, abrasion, and exposure to corrosive substances. FEP heat shrink tubing, crafted from a robust fluoropolymer, excels in these conditions. Its advanced chemical resistance protects against acids, bases, and solvents, ensuring long-term reliability. Unlike some alternatives, this material resists cracking and degradation, even under continuous use.

Lifespan in high-temperature and corrosive environments

The lifespan of heat shrink tubing depends on its ability to endure extreme temperatures and corrosive environments. FEP heat shrink tubing maintains structural integrity across a wide thermal range, from -200°C to 200°C. This makes it ideal for industries requiring prolonged exposure to high heat or aggressive chemicals. Its longevity surpasses many other available heat shrink tubing materials, reducing the need for frequent replacements and ensuring cost-effectiveness over time.

Flexibility and Ease of Installation

Tubing shrink ratios (1.3:1 to 2:1) for various cable sizes

Flexibility during installation is another critical factor. FEP heat shrink tubing offers shrink ratios ranging from 1.3:1 to 2:1, allowing it to conform to cables and components of varying sizes. This adaptability simplifies the installation process, especially in applications with irregularly shaped or tightly packed wiring systems. Compared to PTFE, which often requires higher processing temperatures, FEP provides a more user-friendly solution due to its lower shrink temperature.

Compatibility with different wire and component dimensions

The compatibility of heat shrink products with diverse wire and component dimensions enhances their versatility. Adhesive-lined heat shrink tubing, for instance, provides a secure seal for wires of varying diameters, ensuring protection against moisture and contaminants. FEP heat shrink tubing also offers excellent optical clarity, making it suitable for applications requiring visibility, such as medical devices or precision electronics.

Chemical Resistance and Electrical Insulation

Protection against corrosive substances and UV exposure

Chemical resistance is a hallmark of specialty heat shrink products like FEP heat shrink tubing. Its ability to resist corrosive substances, including hydraulic fluids and cleaning agents, makes it indispensable in industries like automotive and chemical processing. Additionally, its UV resistance ensures durability in outdoor applications, where prolonged exposure to sunlight could degrade lesser materials.

Electrical safety in high-voltage and sensitive applications

In applications with stringent electrical property requirements, FEP heat shrink tubing provides exceptional electrical insulation. Its high dielectric strength safeguards sensitive wiring and components from electrical interference and breakdown. This makes it a preferred choice for high-voltage systems and precision electronics. Furthermore, adhesive-lined heat shrink tubing enhances protection by creating a watertight seal, ensuring safety and reliability in critical environments.

By considering these factors, users can select the most suitable heat shrink product for their specific needs. Whether prioritizing durability, ease of installation, or chemical resistance, FEP heat shrink tubing offers a versatile and reliable solution for a wide range of applications.

Industry-Specific Use Cases for FEP Heat Shrink Tubing Brands

Aerospace and Automotive Applications

High-temperature wiring protection and fuel resistance

In aerospace and automotive industries, heat shrink tubing plays a pivotal role in safeguarding wiring systems. The extreme conditions encountered in these sectors demand materials that can endure high temperatures and resist chemical exposure. FEP heat shrink tubing excels in this regard, offering reliable protection for electrical components. Its ability to withstand temperatures up to 200°C ensures consistent performance during prolonged exposure to heat.

FEP tubing also demonstrates exceptional resistance to aviation fuels and automotive fluids. This makes it an ideal choice for fuel line applications in aerospace engineering. The material’s thermal stability allows it to maintain its structural integrity even during rapid temperature fluctuations experienced in flight operations or engine environments. Additionally, its semi-clear nature provides visibility, enabling technicians to inspect wiring systems without removing the protective layer.

Resistance to hydraulic fluids and environmental stress

Hydraulic systems in aerospace and automotive applications often operate under high pressure and involve exposure to corrosive fluids. FEP heat shrink tubing offers robust resistance to hydraulic fluids, ensuring long-term reliability in these demanding environments. Its chemical resistance protects wiring and components from degradation caused by exposure to oils, solvents, and other harsh substances.

Environmental stress, such as UV radiation and mechanical vibrations, poses another challenge in these industries. FEP tubing’s durability and flexibility make it well-suited for outdoor applications and areas prone to mechanical strain. By providing a secure and protective covering, this heat shrink product enhances the lifespan of wiring systems and reduces maintenance requirements.

Medical and Electronics Applications

Sterilization compatibility and biocompatibility

The medical industry relies heavily on FEP heat shrink tubing for its unique properties. Its biocompatibility ensures safety when used in critical medical devices, such as catheters, endoscopes, and surgical instruments. The tubing’s ability to withstand sterilization processes, including autoclaving and chemical cleaning, makes it indispensable in maintaining hygiene standards.

FEP tubing also serves as a processing aid in catheter manufacturing. It facilitates reflowing catheter shafts and joint bonding, ensuring precision and consistency in production. Its chemically inert nature further enhances its suitability for medical applications, as it does not react with bodily fluids or cleaning agents.

Insulation for sensitive components and optical clarity

In the electronics sector, FEP heat shrink tubing provides essential insulation for sensitive components. Its high dielectric strength ensures electrical insulation, safeguarding circuits and wiring from interference and breakdown. This makes it a preferred choice for high-voltage systems and precision electronics.

The tubing’s optical clarity adds another layer of functionality. It allows technicians to visually inspect components without removing the protective layer, streamlining maintenance and quality control processes. Additionally, its low friction and flexibility make it easy to install, even in tightly packed electronic assemblies. These attributes highlight the versatility of this heat shrink product in addressing the unique challenges of medical and electronics applications.

FEP heat shrink tubing for temperature resistance remains a critical solution for industries requiring reliable performance in extreme conditions. The comparison of Zeus, AccuPath, and TE Connectivity highlights their shared ability to withstand up to 200°C while offering unique strengths tailored to specific applications. Zeus excels in UV resistance and chemical durability, AccuPath stands out in medical and industrial versatility, and TE Connectivity specializes in aerospace and automotive reliability. Selecting the best brand depends on evaluating application needs, such as temperature range, material durability, and industry-specific requirements. Informed decisions ensure optimal performance and long-term value.

FAQ

What are the applications of FEP heat shrink tubing in the medical field?

FEP heat shrink tubing serves multiple purposes in the medical industry. It provides insulation, encapsulation, and protective covering for various components. Common applications include medical instruments, temperature probes, roll covers, lighting systems, hoses, wires, and cables. Its biocompatibility and ability to withstand sterilization processes make it indispensable in healthcare settings.

Why is FEP heat shrink tubing widely adopted in medical applications?

The adoption of FEP heat shrink tubing in medical applications stems from its ability to meet the demands of advanced healthcare technologies. The growing need for minimally invasive procedures and sophisticated medical devices has increased its usage. Additionally, stringent regulatory requirements in the medical field further drive its adoption, ensuring safety and reliability in critical applications.

What is the significance of the 1.3:1 shrink ratio in FEP heat shrink tubing?

The 1.3:1 shrink ratio holds significant importance due to its versatility. This ratio is widely used for encapsulating medical devices and insulating electrical components. Its ability to conform to various shapes and sizes makes it a preferred choice in the medical sector. Market projections indicate that this segment will register the second-highest market share in the coming years.

How does FEP heat shrink tubing compare to PTFE in terms of shrink temperature?

FEP heat shrink tubing requires a lower shrink temperature compared to PTFE. This characteristic reduces the risk of damaging temperature-sensitive materials during installation. While PTFE offers higher temperature resistance, FEP’s lower processing temperature enhances its usability in applications requiring precision and care.

Can FEP heat shrink tubing withstand sterilization processes?

Yes, FEP heat shrink tubing can endure various sterilization methods, including autoclaving and chemical cleaning. Its chemical inertness and thermal stability ensure that it remains effective after repeated sterilization cycles. These properties make it an ideal choice for medical devices and instruments that require stringent hygiene standards.

What industries benefit most from FEP heat shrink tubing?

Industries such as aerospace, automotive, medical, and electronics benefit significantly from FEP heat shrink tubing. In aerospace and automotive sectors, it protects wiring systems from high temperatures and corrosive substances. In the medical field, it ensures biocompatibility and sterilization compatibility. The electronics industry values its electrical insulation and optical clarity for sensitive components.

How does FEP heat shrink tubing perform in high-temperature environments?

FEP heat shrink tubing performs exceptionally well in high-temperature environments. It maintains structural integrity and functionality across a wide operating range, from -200°C to 200°C. This capability ensures reliable performance in demanding applications, such as aerospace, automotive, and industrial settings.

What makes FEP heat shrink tubing suitable for outdoor applications?

FEP heat shrink tubing’s UV resistance makes it highly suitable for outdoor applications. It resists degradation caused by prolonged exposure to sunlight, ensuring durability and longevity. This feature is particularly valuable in industries like aerospace and automotive, where components often face harsh environmental conditions.

Is FEP heat shrink tubing chemically resistant?

Yes, FEP heat shrink tubing exhibits excellent chemical resistance. It protects components from corrosive substances, including acids, bases, solvents, and hydraulic fluids. This property ensures durability and reliability in harsh industrial and chemical processing environments.

How does FEP heat shrink tubing enhance electrical safety?

FEP heat shrink tubing provides exceptional electrical insulation due to its high dielectric strength. It safeguards sensitive wiring and components from electrical interference and breakdown. This makes it a preferred choice for high-voltage systems and precision electronics, ensuring safety and reliability in critical applications.

See Also

The Importance of Ultra-Thin PET Tubing in Healthcare

A Global Comparison of Etched PTFE Liner Producers

Selecting the Ideal PTFE Etched Liner for Your Needs