How Medical Grade FEP Heat Shrink Tubing Builds Multi-Layer Catheters

Medical grade FEP heat shrink tubing in multi-layer catheters plays a critical role in advancing healthcare technology. Its unique properties enhance the performance and safety of medical devices. This tubing withstands high temperatures, ensuring precise assembly during manufacturing. Its non-stick surface simplifies removal, maintaining a clean and efficient process. Additionally, it offers abrasion protection, extending the lifespan of catheters. In healthcare, it serves as a protective coating for surgical instruments and catheters, ensuring sterility and safety. Its biocompatibility makes it suitable for direct contact with human tissues, supporting patient safety and device reliability.

Key Takeaways

FEP heat shrink tubing makes catheters safer and work better. It is safe for the body and resists chemicals.

The tubing can handle high heat, helping with careful assembly. This keeps parts secure and protects them during making.

FEP tubing has a smooth surface that lowers friction. This makes it more comfortable for patients and reduces harm to tissues.

It bends easily, which helps in making complex designs. This makes it great for advanced medical tools and special catheter needs.

AccuPath's FEP heat shrink tubing follows strict rules, ensuring it is safe and reliable for medical use.

The Role of Medical Grade FEP Heat Shrink Tubing in Multi-Layer Catheters

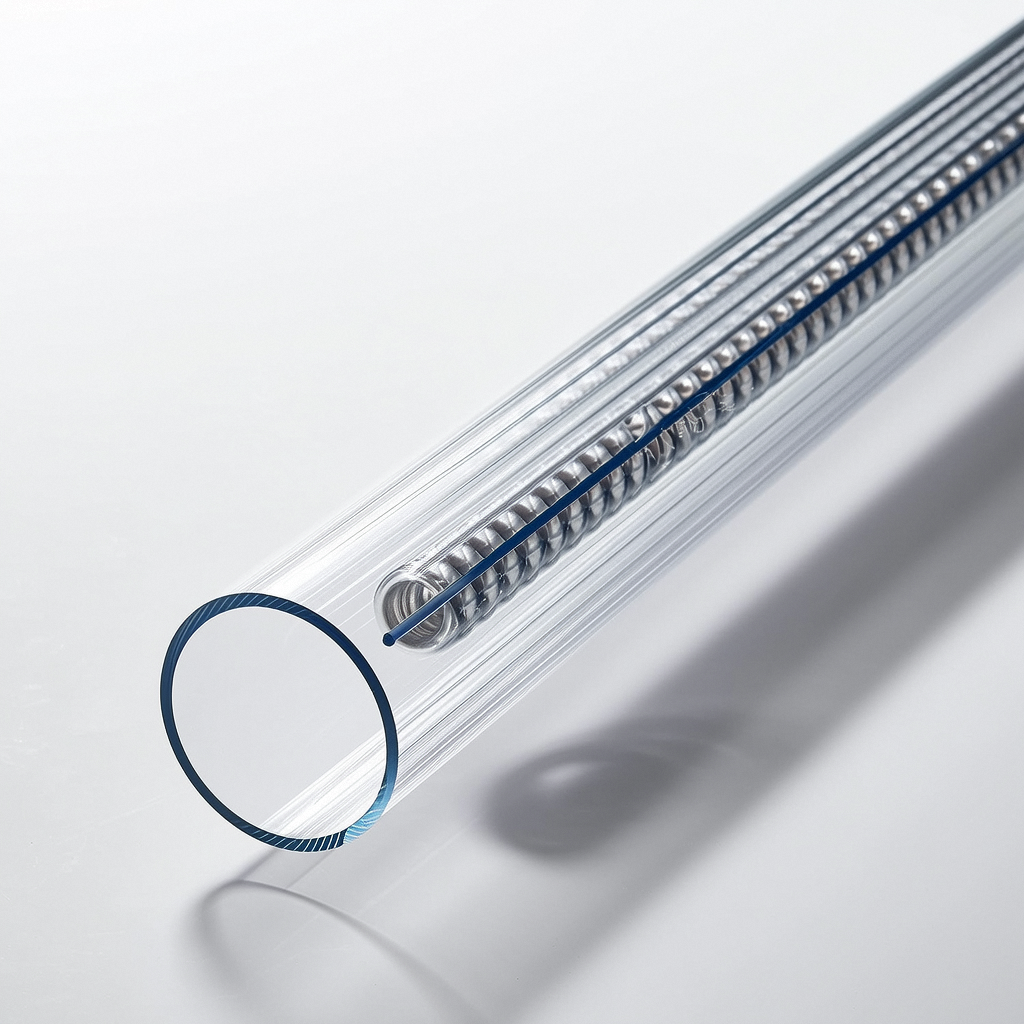

How FEP Tubing Enables Multi-Layer Catheter Assembly

Medical grade FEP heat shrink tubing in multi-layer catheters plays a pivotal role in ensuring precision and safety during assembly. Its biocompatibility allows for safe, prolonged contact with human tissues, making it ideal for medical applications. The tubing’s flexibility supports intricate designs, enabling the creation of complex multilayer shafts with high accuracy. Additionally, its non-stick surface minimizes friction, allowing catheters to glide smoothly during procedures, enhancing both patient comfort and procedural efficiency.

The tubing’s high-temperature resistance is another critical feature. It enables the reflow of thermoplastic materials, ensuring a secure fit and protecting delicate components during the manufacturing process. This property also allows the tubing to adapt to various catheter designs, providing versatility unmatched by alternative materials like silicone. These characteristics make FEP heat shrink tubing an indispensable tool in the assembly of multi-layer catheters.

The Sandwich Structure Design in Catheters

The sandwich structure design in catheters relies on multiple layers of materials to achieve optimal performance. FEP heat shrink tubing acts as a key component in this design, facilitating the bonding of different layers. The tubing’s chemical resistance prevents reactions with biofluids, maintaining the purity of substances during medical procedures. Its transparency allows for visual inspection of the layers, ensuring consistency and quality throughout the manufacturing process.

This design approach enhances the catheter’s structural integrity and functionality. By incorporating FEP tubing, manufacturers can create durable, high-performing devices that meet the rigorous demands of medical applications. The tubing’s ability to withstand harsh conditions further ensures the reliability of the final product.

FEP Tubing as a Manufacturing Aid in Catheter Lamination

FEP heat shrink tubing serves as a vital manufacturing aid in catheter lamination. It is often used as an inner layer or a processing tool to reflow other thermoplastic materials. Its high-temperature resistance ensures that materials bond securely, creating a seamless and durable multilayer shaft. The tubing’s flexibility also supports the integration of complex designs, making it suitable for advanced medical devices.

In addition to its functional benefits, FEP tubing enhances safety and performance. Its chemical resistance protects devices from harsh substances, while its biocompatibility ensures safe interaction with human tissues. These properties make it a preferred choice for manufacturers aiming to produce high-quality, reliable catheters. AccuPath’s FEP heat shrink tubing exemplifies these qualities, offering unmatched performance in medical device manufacturing.

Properties of Medical Grade FEP Heat Shrink Tubing

Heat Shrinkability and Precision in Assembly

Medical grade FEP heat shrink tubing offers exceptional heat shrinkability, which ensures precision during catheter assembly. When heated, the tubing conforms tightly to the underlying components, creating a secure fit. This property protects delicate parts during the manufacturing process, maintaining their integrity. The non-stick surface of FEP tubing allows for easy removal after heating, leaving a clean and smooth assembly. This precision is essential for meeting the high-quality standards required in medical device production.

AccuPath’s FEP heat shrink tubing exemplifies these qualities, providing manufacturers with a reliable solution for creating intricate catheter designs. Its ability to adapt to various shapes and sizes makes it indispensable in the production of advanced medical devices.

Biocompatibility and Safety for Medical Applications

Biocompatibility is a critical property of FEP heat shrink tubing, ensuring its safe use in medical applications. The tubing interacts safely with human tissues, minimizing the risk of adverse reactions. Its inert nature prevents reactions with bodily fluids, reducing contamination and infection risks. Additionally, the non-stick surface of FEP tubing prevents the accumulation of biological substances, further enhancing patient safety.

These features make FEP tubing an ideal choice for medical devices that require prolonged contact with the human body. AccuPath’s medical-grade FEP tubing meets stringent biocompatibility standards, ensuring both safety and reliability in healthcare environments.

Chemical Resistance and Durability in Harsh Conditions

FEP heat shrink tubing demonstrates remarkable chemical resistance, which ensures durability in challenging medical environments. Its chemically inert surface prevents reactions with drugs, sterilizing agents, and bodily fluids. This resistance protects medical devices from degradation caused by corrosive chemicals, extending their lifespan. The tubing’s ability to withstand harsh conditions makes it suitable for use in environments where exposure to aggressive substances is common.

AccuPath’s FEP heat shrink tubing stands out for its durability and reliability. Its robust properties make it a preferred choice for manufacturers aiming to produce long-lasting, high-performing medical devices.

Benefits of Using FEP Tubing in Multi-Layer Catheter Manufacturing

Enhancing Layer Bonding and Structural Integrity

FEP tubing significantly improves the bonding of layers in multi-layer catheters. Its high-temperature resistance ensures that materials fuse securely during the manufacturing process, preserving the structural integrity of the device. The tubing’s flexibility allows it to conform to intricate designs, enhancing the adhesion between layers. This adaptability ensures that catheters maintain their durability even under mechanical stress.

The non-stick surface of FEP tubing minimizes friction, which reduces the risk of tissue damage during medical procedures. This property also enhances the performance of catheters, making them more efficient and reliable. AccuPath’s FEP heat shrink tubing exemplifies these qualities, offering manufacturers a dependable solution for creating structurally sound medical devices.

Supporting Complex Designs and Customization

FEP tubing supports the creation of complex catheter designs by offering exceptional flexibility and customization options. Manufacturers can tailor the tubing’s dimensions, including diameter and wall thickness, to meet specific requirements. Thinner walls are ideal for microcatheters, while thicker walls provide added durability for high-pressure applications.

The tubing’s ability to bend without kinking simplifies routing in intricate setups, ensuring smooth operation in advanced medical devices. Its chemical resistance prevents reactions with biofluids, maintaining the purity of substances during procedures. These features make FEP tubing an indispensable tool for producing customized, high-performing catheters. AccuPath’s heat shrink tubing stands out for its ability to adapt to diverse design needs, supporting innovation in medical device manufacturing.

Improving Patient Safety and Device Performance

FEP tubing enhances patient safety by offering biocompatibility and chemical resistance. Its inert nature prevents reactions with bodily fluids and medications, reducing the risk of adverse effects. The non-stick surface minimizes residue buildup, lowering contamination risks and ensuring a sterile environment. Additionally, the tubing’s thermal stability allows it to withstand high-temperature sterilization processes without compromising its integrity.

The durability of FEP tubing contributes to consistent device performance during critical procedures. Its transparency enables easy monitoring of fluids, improving usability for healthcare professionals. By incorporating AccuPath’s FEP heat shrink tubing, manufacturers can produce medical devices that prioritize patient safety and deliver reliable performance.

Medical Grade Quality Assurance with FEP Tubing

Meeting Regulatory and Industry Standards

Medical-grade FEP heat shrink tubing must meet stringent regulatory and industry standards to ensure its safety and reliability in healthcare applications. Compliance with ISO certifications, such as ISO 13485, demonstrates adherence to international medical device standards. This certification ensures that the tubing is manufactured under strict quality control processes, minimizing risks and enhancing product consistency. Additionally, FDA approval is essential for confirming that the tubing meets rigorous biocompatibility and performance criteria. These certifications validate that FEP tubing is safe for prolonged contact with human tissues and resistant to chemical interactions with bodily fluids or medications.

FEP tubing also complies with USP Class VI standards, which confirm its suitability for medical and pharmaceutical use. These certifications guarantee that the tubing is free from harmful substances and does not compromise patient safety. By meeting these regulatory requirements, manufacturers can confidently use FEP tubing in critical medical devices, including multi-layer catheters. AccuPath’s FEP heat shrink tubing exemplifies this commitment to quality, offering products that meet or exceed these stringent standards.

Note: Regulatory compliance not only ensures patient safety but also builds trust in the medical device manufacturing industry, fostering innovation and reliability.

Ensuring Consistency and Reliability in Manufacturing

Consistency and reliability are vital in the production of FEP heat shrink tubing. Leading manufacturers implement robust measures to maintain high-quality standards throughout the manufacturing process. Suppliers play a crucial role by delivering tubing within predictable timeframes, ensuring uninterrupted production schedules. Many suppliers invest in advanced inventory management systems and strategic distribution networks to guarantee timely deliveries. On-time delivery performance strengthens trust and fosters long-term partnerships between manufacturers and suppliers.

Effective customer support further enhances reliability. Prompt responses to technical inquiries help manufacturers address challenges during the design phase, reducing errors and accelerating development timelines. Suppliers offering technical assistance enable manufacturers to achieve better outcomes, particularly when creating complex medical devices. Multiple communication channels also improve accessibility, reflecting a supplier’s dedication to customer satisfaction.

AccuPath stands out as a trusted supplier of FEP heat shrink tubing. Its commitment to timely delivery, technical support, and product quality ensures that manufacturers can rely on its tubing for consistent performance in medical device manufacturing.

Why FEP Tubing is Essential in Medical Device Manufacturing

Unique Advantages Over Alternative Materials

FEP tubing offers unique advantages that set it apart from alternative materials in medical device manufacturing. Its exceptional chemical resistance ensures durability, even when exposed to harsh substances like sterilizing agents or biofluids. This property makes it a reliable choice for critical applications, such as braided catheter designs, where material integrity is paramount. The tubing’s thermal stability allows it to endure high-temperature sterilization processes without compromising its structure, ensuring consistent performance over time.

The non-stick surface of FEP tubing enhances usability by reducing friction, which is particularly beneficial in applications like intravenous lines. Its transparency enables healthcare professionals to monitor fluid flow easily, improving procedural efficiency. Compared to materials like PVC, FEP tubing demonstrates superior flexibility and durability, making it ideal for intricate designs and long-term use. AccuPath’s FEP heat shrink tubing exemplifies these qualities, providing manufacturers with a dependable solution for creating advanced medical devices.

Long-Term Reliability in Medical Applications

FEP tubing significantly contributes to the longevity and reliability of medical devices. Its strong molecular structure resists wear and tear, making it suitable for demanding applications such as braid-reinforced catheters. This durability reduces the need for frequent replacements, leading to cost savings for healthcare providers. The tubing’s chemical resistance further enhances its lifespan by preventing degradation caused by exposure to medications or bodily fluids.

The non-stick surface simplifies cleaning and sterilization, ensuring that devices remain safe and functional over time. Additionally, FEP tubing maintains its integrity during repeated sterilization cycles, a critical factor for surgical tools and implantable devices. AccuPath’s FEP heat shrink tubing stands out for its ability to deliver consistent performance, making it a preferred choice for manufacturers aiming to produce reliable medical devices.

Contribution to the Evolution of Catheter Technology

FEP tubing has played a pivotal role in advancing catheter technology. Its chemical resistance prevents reactions with biofluids, ensuring the safety and effectiveness of medical procedures. The tubing’s non-stick surface minimizes friction, enhancing patient comfort and procedural efficiency. Its flexibility allows it to adapt to complex designs, supporting innovations like braid-reinforced catheters.

Recent advancements in FEP tubing technology have further revolutionized catheter manufacturing. Custom dimensions and surface modifications enable the creation of highly specialized devices, such as braided catheters for vascular procedures. The integration of advanced manufacturing techniques, including 3D printing, has improved the precision and performance of these devices. AccuPath’s FEP heat shrink tubing continues to drive innovation in this field, offering solutions that meet the evolving demands of medical device manufacturing.

Medical grade FEP heat shrink tubing in multi-layer catheters has revolutionized the manufacturing of advanced medical devices. Its biocompatibility and chemical resistance ensure safe interaction with human tissues while protecting against harsh substances. The tubing’s high-temperature tolerance and flexibility allow for precise assembly and integration into complex designs, making it indispensable in catheter production.

Key properties like thermal stability and durability contribute to the reliability of medical devices, even under demanding conditions. These features not only enhance device performance but also improve patient outcomes by reducing risks and ensuring consistent functionality during critical procedures. As medical technology evolves, FEP tubing continues to play a pivotal role in driving innovation and supporting the development of safer, more effective healthcare solutions.

Tip: AccuPath’s FEP heat shrink tubing exemplifies these qualities, offering manufacturers a trusted solution for producing high-quality, multi-layer catheters.

FAQ

What makes FEP heat shrink tubing suitable for medical applications?

FEP heat shrink tubing offers biocompatibility, chemical resistance, and thermal stability. These properties ensure safe interaction with human tissues and durability in harsh environments. Its non-stick surface and flexibility make it ideal for creating complex medical devices like multi-layer catheters. AccuPath’s tubing exemplifies these qualities.

How does FEP tubing improve catheter performance?

FEP tubing enhances catheter performance by reducing friction with its non-stick surface. This minimizes tissue damage during procedures. Its transparency allows for easy monitoring, while its flexibility supports intricate designs. AccuPath’s FEP tubing ensures reliable performance in advanced medical devices.

Can FEP tubing withstand sterilization processes?

Yes, FEP tubing resists high-temperature sterilization without compromising its structure. Its chemical resistance protects it from degradation caused by sterilizing agents. These features make it a dependable choice for reusable medical devices. AccuPath’s FEP heat shrink tubing maintains integrity through repeated sterilization cycles.

Why is chemical resistance important in FEP tubing?

Chemical resistance prevents reactions with biofluids, medications, and sterilizing agents. This ensures the tubing remains durable and safe for medical use. It also protects devices from contamination and degradation. AccuPath’s FEP tubing offers exceptional chemical resistance for reliable performance.

How does AccuPath support medical device manufacturers?

AccuPath provides high-quality FEP heat shrink tubing that meets stringent medical standards. Its products offer precision, durability, and customization options. AccuPath also ensures timely delivery and technical support, helping manufacturers create innovative and reliable medical devices.

Tip: AccuPath’s FEP heat shrink tubing combines advanced properties with consistent quality, making it a trusted choice for medical device manufacturing.

See Also

Advantages of FEP Heat Shrink Tubing for Healthcare

New Developments in FEP Heat Shrink Tubing for Medicine

Understanding FEP Autoclavable Heat Shrink Tubing Easily

FEP Heat Shrink Tubing Producers Revolutionizing Medical Equipment