FEP Heat Shrink Tubing Manufacturer: A Game-Changer for Medical Devices

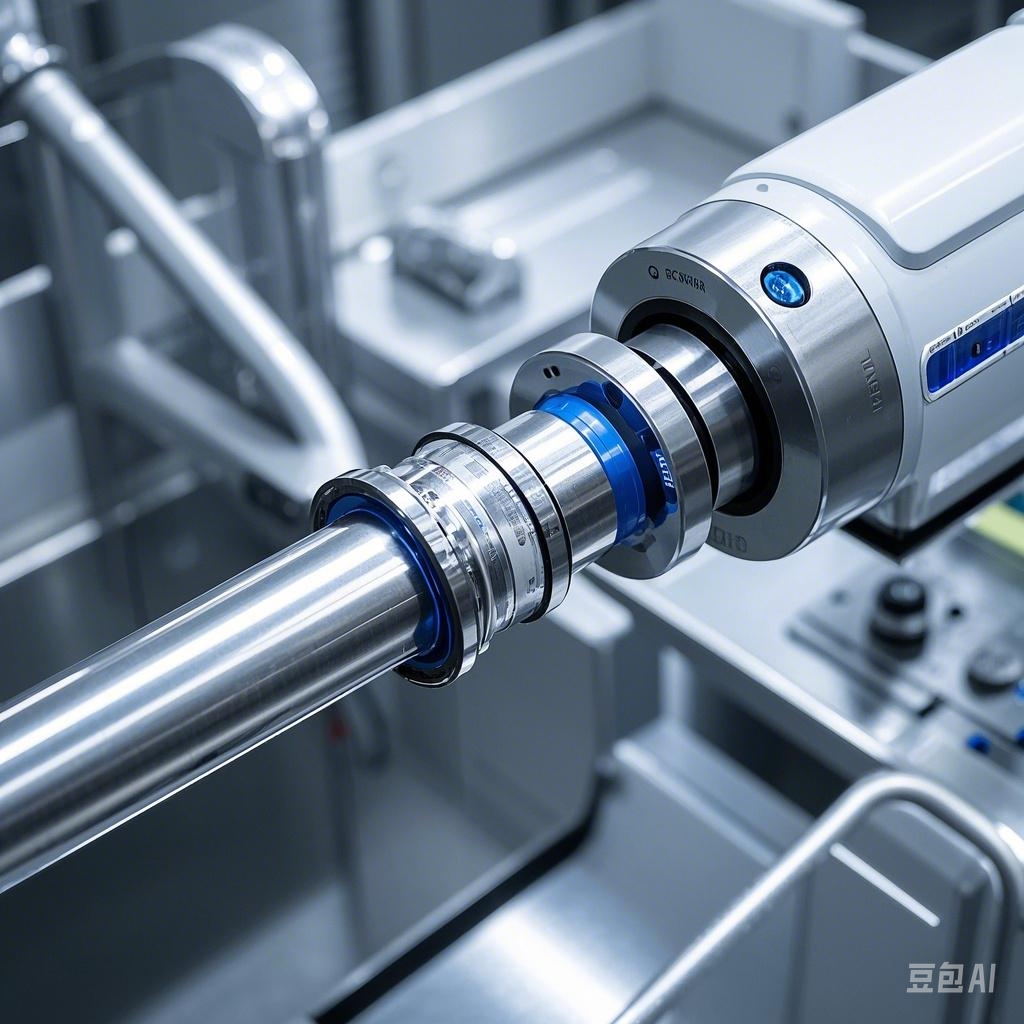

FEP heat shrink tubing plays a pivotal role in medical device manufacturing, offering unmatched biocompatibility and sterilization compatibility. As a leading FEP Heat Shrink Tubing Manufacturer, its ability to meet stringent quality standards ensures reliability in critical applications. The tubing's unique properties, including chemical resistance, thermal stability, and precision, make it indispensable for creating advanced medical devices.

The growing demand for minimally invasive procedures and catheter delivery systems has further fueled the adoption of FEP heat shrink tubing. The market, valued at USD 136.1 million in 2023, is projected to grow at a 7.6% CAGR, reaching USD 241.9 million by 2031. This growth reflects the tubing's versatility and its role in addressing space constraints and enhancing device performance.

AccuPath's FEP heat shrink tubing exemplifies these qualities. Manufactured under ISO 13485 standards, it ensures material consistency, uniform shrink ratios, and thermal stability. These attributes make it a cornerstone in the production of safe and innovative medical devices.

Key Takeaways

FEP heat shrink tubing is important for medical tools. It is safe for the body and can handle cleaning processes.

FEP tubing can be customized in size and color. This makes it easier to use and better for production.

Picking a trusted supplier like AccuPath gives top-quality tubing. It follows strict rules, making it safer for medical use.

FEP tubing is flexible and works in many ways. It is used in making catheters and protecting delicate electronics.

It lasts a long time, cutting down on waste. Installing it uses less energy, which helps the environment.

Key Properties of FEP Heat Shrink Tubing

Biocompatibility and Sterilization Compatibility

FEP heat shrink tubing stands out in medical applications due to its exceptional biocompatibility and sterilization compatibility. Its non-porous surface prevents contamination, ensuring the sterility of medical devices during storage and transportation. This property is critical in healthcare environments where hygiene standards are non-negotiable. Additionally, FEP tubing can endure repeated sterilization cycles, including autoclaving and gamma radiation, without compromising its structural integrity. This durability and resistance to high-pressure steam and elevated temperatures make it a reliable choice for maintaining device performance.

The chemical resistance of FEP tubing further enhances its biocompatibility. It protects medical devices from exposure to harsh substances, ensuring safe interaction with human tissues. These qualities make FEP heat shrink tubing indispensable for applications requiring both biocompatibility and chemical resistance. AccuPath's FEP Heat Shrink Tubing, manufactured under ISO 13485 standards, exemplifies these attributes, offering material consistency and performance that meet the rigorous demands of the medical industry.

Precision, Customization, and Versatility

FEP heat shrink tubing delivers unmatched precision, making it a cornerstone in advanced medical device manufacturing. Its ability to conform tightly to intricate and irregular shapes ensures a secure fit, which is crucial for the performance of devices like catheters and electrosurgical tools. The tubing also minimizes friction, allowing smooth movement through tissues and reducing the risk of damage during procedures. Its high dielectric properties provide insulation for sensitive components, enhancing both safety and functionality.

Customization options further elevate the versatility of FEP tubing. Manufacturers can tailor diameters, wall thicknesses, and lengths to meet specific design requirements, minimizing material waste. Custom colors enable easy identification, while specialized packaging ensures sterility. These features make FEP tubing adaptable to a wide range of medical applications, from encapsulating delicate electronics to insulating wiring in compact devices.

AccuPath's FEP Heat Shrink Tubing combines precision, durability, and customization, making it a trusted solution for medical device manufacturers. Its ability to withstand harsh conditions while maintaining material consistency and performance underscores its value in creating innovative and reliable healthcare technologies.

Applications in Medical Device Manufacturing

Catheter Lamination and Tip Forming

FEP heat shrink tubing plays a vital role in catheter manufacturing, particularly in lamination and tip forming processes. Its ability to conform tightly to intricate shapes ensures a secure and precise fit, which is essential for maintaining the structural integrity of catheters. During assembly, the tubing acts as a protective layer, safeguarding components like braided shafts and spring coils. This protection enhances durability and prevents fluid leakage, ensuring safety in devices such as rotary spring cutters.

The tubing's chemical resistance and high-temperature tolerance make it ideal for catheter tip forming. It withstands sterilization processes, including autoclaving, without compromising its performance. Additionally, its flexibility allows it to adapt to various shapes and sizes, ensuring a seamless fit around components. These attributes make FEP heat shrink tubing indispensable in catheter manufacturing, where precision and reliability are paramount.

Encapsulation of Sensitive Components

Protecting sensitive components is a critical requirement in medical device manufacturing. FEP heat shrink tubing excels in this area by providing robust encapsulation for delicate parts such as catheters, stents, and surgical instruments. Its biocompatibility ensures safe interaction with human tissues, while its non-stick surface simplifies installation over intricate components.

In electronics, the tubing offers reliable insulation and protection for wires, cables, and other components. It shields these parts from environmental factors like moisture, UV radiation, and dust, ensuring their functionality and longevity. By serving as a protective covering for medical devices, FEP heat shrink tubing enhances both safety and performance in demanding environments.

Insulation and Protection of Wires and Electronics

FEP heat shrink tubing provides reliable electrical insulation for wires and electronics in medical devices. Its high dielectric properties and ultra-thin walls ensure effective insulation without adding bulk to compact devices. This makes it an ideal choice for encapsulating components like catheters and stents, where space constraints are a concern.

The tubing's transparency allows for visual inspection of underlying components, which is crucial for quality control. Its resistance to moisture, chemicals, and extreme temperatures ensures consistent performance in diverse environments. By protecting sensitive components from electrical irritation and environmental factors, FEP heat shrink tubing supports the development of innovative and reliable medical technologies.

AccuPath's FEP Heat Shrink Tubing exemplifies these qualities, offering unmatched precision, durability, and customization. Its ability to serve as a protective covering for medical devices underscores its value in advancing medical device manufacturing.

Choosing the Right FEP Heat Shrink Tubing Manufacturer

Importance of Quality Standards and Certifications

Selecting a reliable FEP heat shrink tubing manufacturer is critical for ensuring product quality and safety in medical device manufacturing. Certifications, such as ISO certifications, play a pivotal role in demonstrating a supplier's commitment to quality and regulatory compliance. ISO 13485, for instance, reflects adherence to international standards for medical device production. Manufacturers with these certifications ensure that their FEP heat shrink tubing meets the rigorous demands of the healthcare industry. Additionally, FDA and medical-grade compliance is non-negotiable for tubing used in medical applications, as it guarantees biocompatibility and safety.

High-quality tubing must withstand wear, chemicals, and extreme temperatures to maintain performance in demanding environments. Compliance with certifications ensures that the tubing resists these challenges, enhancing its reliability. Suppliers like AccuPath, which operate under ISO 13485 standards, provide consistent material quality and meet stringent regulatory requirements. This level of compliance safeguards the integrity of medical devices, reducing the risk of failures that could compromise patient safety.

Tip: Partnering with a certified supplier not only ensures product quality and range but also minimizes risks associated with non-compliance, such as device malfunctions or regulatory penalties.

Customization Options and Scalability for Medical Applications

Customization and scalability are essential factors when choosing a supplier for FEP heat shrink tubing. Medical device manufacturing often requires tubing tailored to specific dimensions, wall thicknesses, and performance characteristics. Suppliers offering extensive customization options can address these needs effectively. For example, AccuPath provides tubing with a wide range of diameters and shrink ratios, ensuring compatibility with various medical applications. Custom colors and packaging further enhance usability and identification during production.

Scalability is equally important for large-scale medical projects. Manufacturers must select suppliers with robust capabilities to handle high-volume orders without compromising quality. The following table highlights key criteria for evaluating scalability:

Criteria | Description |

|---|---|

Supplier Capabilities | Manufacturers select suppliers with robust manufacturing capabilities and efficient processes. |

Production Volume | High-volume projects necessitate suppliers that can handle large-scale orders without quality loss. |

Customization and Support | Prioritizing suppliers that offer customization ensures tailored solutions for specific needs. |

AccuPath excels in both customization and scalability, making it a trusted partner for medical device manufacturers. Its ability to deliver high-quality FEP heat shrink tubing at scale ensures that manufacturers can meet growing market demands while maintaining compliance with industry standards.

FEP heat shrink tubing has revolutionized medical device manufacturing by enhancing safety, reliability, and innovation. Its unique properties, such as chemical resistance, thermal stability, and biocompatibility, make it indispensable for creating advanced healthcare technologies. Manufacturers benefit from its versatility, which allows for precise customization to meet specific application needs.

Partnering with a trusted supplier like AccuPath ensures access to high-quality FEP heat shrink tubing. Their commitment to ISO 13485 standards and customizable solutions empowers manufacturers to meet the stringent demands of the medical industry while advancing innovation.

FAQ

What makes AccuPath's FEP Heat Shrink Tubing unique?

AccuPath's FEP Heat Shrink Tubing offers a 2:1 shrink ratio, high transparency, and excellent dielectric properties. It is manufactured under ISO 13485 standards in a cleanroom environment, ensuring superior quality and biocompatibility. Its customizable options make it ideal for diverse medical applications.

Can FEP heat shrink tubing withstand sterilization processes?

Yes, FEP heat shrink tubing resists high temperatures and harsh sterilization methods, including autoclaving and gamma radiation. Its structural integrity remains intact, ensuring reliable performance in medical environments where repeated sterilization is essential.

How does FEP heat shrink tubing enhance medical device safety?

FEP tubing provides robust insulation, chemical resistance, and biocompatibility. It protects sensitive components from environmental factors like moisture and corrosion. These properties ensure medical devices remain safe and functional during use, reducing risks to patients.

Is AccuPath's FEP Heat Shrink Tubing customizable?

AccuPath offers extensive customization options, including tailored diameters, wall thicknesses, and lengths. Custom colors and specialized packaging are also available, enabling manufacturers to meet specific design and production requirements efficiently.

Why is ISO 13485 certification important for FEP heat shrink tubing?

ISO 13485 certification ensures that the tubing meets stringent quality and regulatory standards for medical devices. It guarantees material consistency, safety, and reliability, making it a trusted choice for healthcare applications.

See Also

FEP Non-Toxic Heat Shrink Tubing Revolutionizes Industrial Applications

Latest Developments in FEP Heat Shrink Tubing for Healthcare

Leading Suppliers of FEP Heat Shrink Tubing for Medical Needs

Advantages of Using FEP Heat Shrink Tubing in Healthcare

Selecting Ideal FEP Biocompatible Heat Shrink Tubing for Applications