Emerging Trends in FEP Heat Shrink Tubing for Medical Devices

FEP heat shrink tubing has revolutionized medical device technology by enhancing precision and safety. Its exceptional properties, such as chemical inertness and high-temperature resistance, make it indispensable in critical applications. This tubing plays a pivotal role in minimally invasive procedures, where its transparency and flexibility support intricate operations. Recent innovations have further elevated its performance, ensuring durability and biocompatibility. These advancements not only improve patient outcomes but also align with the growing demand for safer and more efficient medical solutions. FEP Heat Shrink Tubing for Endoscopic Devices exemplifies its transformative impact on modern healthcare.

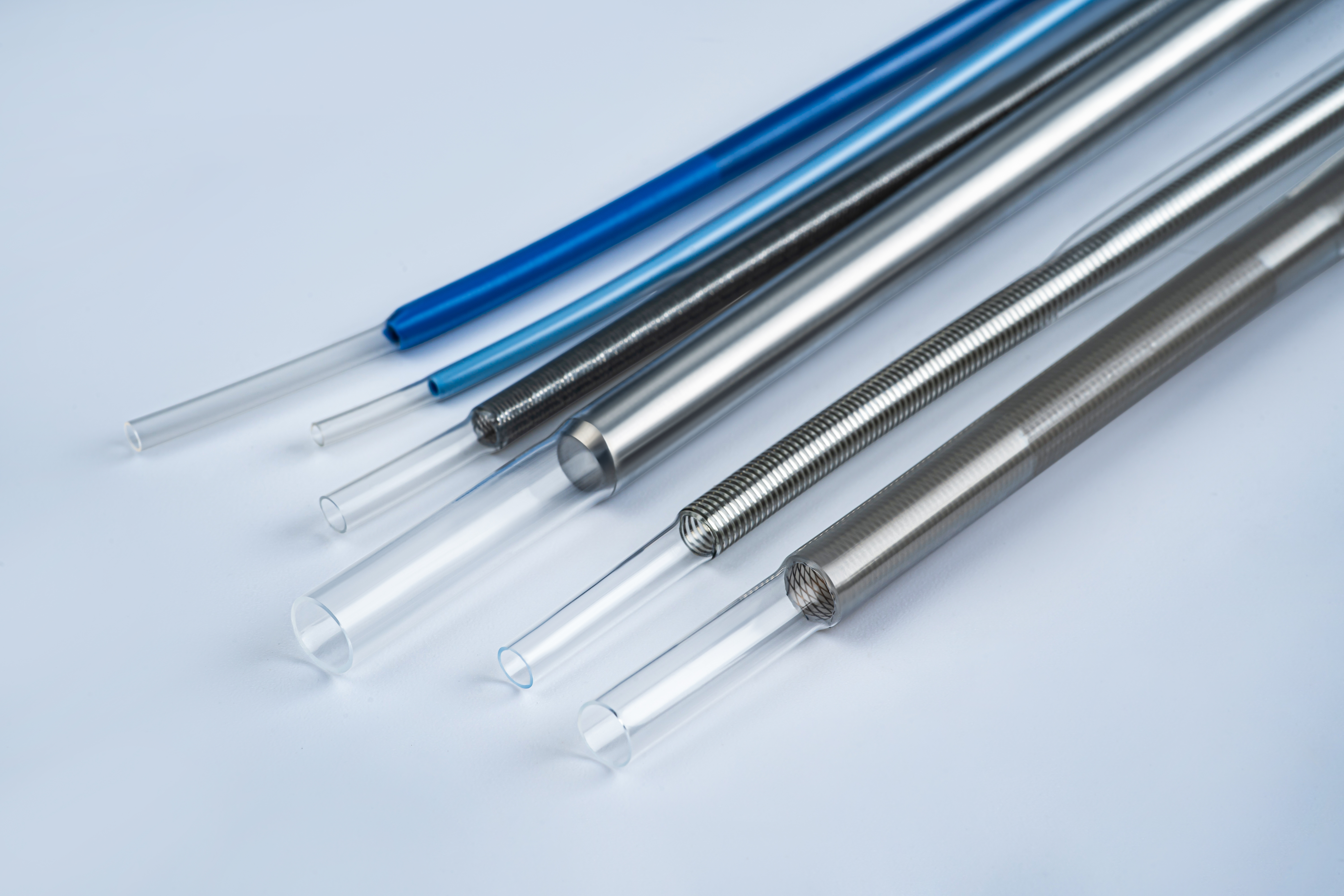

Overview of FEP Heat Shrink Tubing

Key Properties of FEP Heat Shrink Tubing

High-temperature resistance and chemical inertness

FEP heat shrink tubing exhibits exceptional resistance to high temperatures and chemical exposure. This property ensures its reliability in demanding medical environments, where devices often encounter sterilization processes and harsh chemicals. The tubing maintains its structural integrity and performance under extreme conditions, making it a preferred choice for medical device manufacturers. Its chemical inertness prevents reactions with sensitive components, ensuring the safety and longevity of medical instruments.

Transparency and flexibility for medical applications

The transparency of FEP heat shrink tubing allows medical professionals to visually monitor the underlying components during procedures. This feature proves invaluable in applications such as catheters and guide wires, where precision is critical. Additionally, its flexibility supports intricate designs and movements, enabling seamless integration into advanced medical devices. These attributes enhance the functionality and usability of medical tools, particularly in minimally invasive surgeries.

Biocompatibility and sterilization compatibility

Biocompatibility stands as a cornerstone of FEP heat shrink tubing's suitability for medical use. Its compatibility with human tissue minimizes the risk of adverse reactions, ensuring patient safety. Furthermore, the tubing withstands rigorous sterilization methods, including autoclaving and chemical treatments, without compromising its properties. This durability ensures that medical devices remain sterile and effective throughout their lifecycle.

Applications of FEP Heat Shrink Tubing for Endoscopic Devices

Catheters and guide wires

FEP heat shrink tubing plays a vital role in the construction of catheters and guide wires. It provides a smooth, protective outer layer that facilitates easy navigation through the vasculature. This reduces the risk of tissue damage during procedures. Its low coefficient of friction enhances maneuverability, improving the precision and efficiency of surgical interventions. These qualities make it indispensable in vascular and endoscopic applications.

Insulation for electrical components

In medical devices, electrical components require reliable insulation to ensure safety and functionality. FEP heat shrink tubing serves as an effective insulator, protecting sensitive circuits from external interference and environmental factors. Its thermal stability and chemical resistance further enhance its performance in electrosurgical instruments and diagnostic equipment. This insulation capability ensures consistent and accurate device operation.

Encapsulation of sensitive components

FEP heat shrink tubing provides robust encapsulation for delicate medical components. It shields these parts from mechanical stress, abrasion, and contamination, extending their operational lifespan. This encapsulation proves particularly beneficial in devices used for minimally invasive procedures, where precision and reliability are paramount. By safeguarding sensitive elements, the tubing contributes to the overall durability and effectiveness of medical instruments.

Key Advancements in FEP Heat Shrink Tubing

Improved Biocompatibility

Enhanced safety for patient-facing applications

FEP heat shrink tubing has achieved remarkable progress in ensuring high biocompatibility, making it safer for patient-facing applications. Its compatibility with human tissue minimizes the risk of adverse reactions during medical procedures. This advancement supports the growing demand for safer medical devices, particularly in applications involving direct contact with the human body. By meeting stringent safety standards, FEP tubing enhances patient trust and ensures reliable performance in critical healthcare settings.

Compliance with stricter medical regulations

The medical industry faces increasingly rigorous regulatory requirements, such as ISO 10993 for biocompatibility. FEP heat shrink tubing complies with these standards, ensuring its suitability for use in medical devices. Manufacturers benefit from this compliance by gaining a competitive edge in the market. Regulatory adherence not only guarantees patient safety but also fosters innovation in the development of advanced medical technologies. This alignment with global health regulations positions FEP tubing as a preferred material in the medical sector.

Thinner Wall Designs

Reduced bulk for minimally invasive procedures

Advances in medical technology have driven the need for thinner and more efficient materials. FEP heat shrink tubing now features thinner wall designs, reducing bulk in medical devices. This improvement is particularly beneficial for minimally invasive procedures, where compact and precise instruments are essential. The reduced thickness allows for smoother navigation through narrow pathways, enhancing the effectiveness of surgical interventions. These designs cater to the growing demand for less invasive and more patient-friendly medical solutions.

Improved flexibility and precision

Thinner wall designs also contribute to improved flexibility and precision in medical devices. FEP tubing adapts seamlessly to intricate device structures, enabling enhanced maneuverability during procedures. This flexibility supports the development of advanced diagnostic tools and surgical instruments. By combining precision with adaptability, FEP tubing meets the evolving needs of healthcare professionals, ensuring optimal performance in complex medical environments.

Enhanced Durability and Performance

Resistance to wear and tear in demanding environments

FEP heat shrink tubing demonstrates exceptional durability, withstanding wear and tear in challenging medical environments. Its high tensile strength and chemical resistance ensure reliable performance under extreme conditions. This durability proves essential for devices subjected to repeated sterilization processes and mechanical stress. By maintaining structural integrity, FEP tubing extends the lifespan of medical instruments, reducing the need for frequent replacements.

Longer lifespan for medical devices

The enhanced durability of FEP tubing directly contributes to the longevity of medical devices. Its resistance to abrasion and environmental factors ensures consistent functionality over time. This reliability supports the increasing demand for high-performance medical components in the global healthcare market. As the industry continues to expand, FEP tubing remains a cornerstone material for durable and efficient medical solutions.

Innovations in FEP Heat Shrink Tube Technology

AccuPath's 1.8:1 shrink ratio Translucent PHST

AccuPath has introduced a groundbreaking innovation with its 1.8:1 shrink ratio Translucent PHST. This advanced tubing solution addresses the challenges of catheter-based technologies by offering a peelable design that simplifies removal without damaging delicate components. The translucent nature of the tubing enhances visibility during the manufacturing process, enabling precise alignment and reducing errors.

The unique shrink ratio of 1.8:1 provides greater flexibility in accommodating varying device diameters, making it suitable for a wide range of medical applications. This feature ensures a snug fit over components, improving the structural integrity of devices such as catheters and guide wires.

"Our heat shrink tubing is designed to meet the evolving needs of the medical industry, providing both functionality and efficiency," states AccuPath in its product announcement. This innovation reflects the company's commitment to advancing fluoroplastic technologies for medical applications.

Thin Wall FEP HST for interventional therapies

AccuPath's Thin Wall FEP Heat Shrink Tubing represents another significant advancement in medical device technology. Designed specifically for interventional therapies, this tubing leverages the low coefficient of friction inherent to FEP materials. This property enhances the performance of guide wires and catheters, ensuring smooth navigation through complex anatomical pathways. The thin wall design reduces the overall bulk of medical devices, supporting the trend toward minimally invasive procedures.

The durability of this tubing ensures resistance to wear and tear, even in demanding environments. Its chemical inertness and high-temperature resistance make it ideal for use in sterilization processes, maintaining the integrity of medical devices over extended periods. By combining these features, AccuPath's Thin Wall FEP HST enables the development of lightweight, flexible, and reliable tools for interventional therapies.

This innovation aligns with the growing demand for advanced materials in the healthcare sector. The tubing's ability to enhance precision and maneuverability in medical devices underscores its importance in improving patient outcomes. Junkosha's focus on developing cutting-edge solutions demonstrates its leadership in the field of fluoroplastic technologies.

Emerging Trends in Medical Applications

Use in Minimally Invasive Procedures

Support for smaller, more precise instruments

The demand for minimally invasive procedures has driven the development of smaller and more precise medical instruments. FEP heat shrink tubing for endoscopic devices plays a critical role in enabling these advancements. Its exceptional flexibility allows it to conform to intricate device designs, ensuring seamless integration with compact surgical tools. This adaptability supports the creation of instruments that navigate narrow anatomical pathways with ease, reducing trauma to surrounding tissues.

The tubing's transparency further enhances its utility in these applications. Medical professionals can monitor the underlying components during procedures, ensuring accurate placement and operation. By combining flexibility with visibility, FEP tubing has become indispensable in modern surgical practices. Its contribution to the development of smaller, more efficient instruments underscores its importance in advancing minimally invasive techniques.

Applications in endoscopy and laparoscopy

Endoscopic procedures and laparoscopic surgeries rely heavily on the precision and reliability of medical devices. FEP heat shrink tubing for endoscopic devices provides the necessary insulation and protection for these tools. Its chemical inertness ensures compatibility with sterilization processes, maintaining the integrity of devices used in these procedures.

In endoscopy, the tubing encapsulates sensitive components, shielding them from mechanical stress and contamination. This protection extends the lifespan of devices, reducing the need for frequent replacements. In laparoscopy, the tubing's flexibility supports the maneuverability of instruments, enabling surgeons to perform complex operations with greater accuracy. These attributes make FEP tubing a cornerstone material in the evolution of endoscopic and laparoscopic technologies.

Advancements in Catheters and Guide Wires

Improved maneuverability and patient comfort

Catheters and guide wires have seen significant improvements in maneuverability and patient comfort due to advancements in FEP heat shrink tubing. The tubing's low coefficient of friction facilitates smooth navigation through the vasculature, minimizing resistance and reducing the risk of tissue damage. This feature enhances the precision of medical procedures, ensuring better outcomes for patients.

The flexibility of FEP tubing also contributes to patient comfort. It allows devices to adapt to the natural contours of the body, reducing discomfort during insertion and use. These advancements align with the growing demand for patient-centric medical solutions, highlighting the tubing's role in improving healthcare experiences.

Integration with advanced imaging technologies

The integration of advanced imaging technologies with catheters and guide wires has transformed medical diagnostics and treatments. FEP heat shrink tubing supports this integration by providing a reliable protective layer for sensitive imaging components. Its transparency ensures that imaging signals remain unobstructed, enabling accurate visualization of internal structures.

This compatibility with imaging technologies enhances the functionality of medical devices, allowing healthcare professionals to diagnose and treat conditions with greater precision. The tubing's ability to support these advancements underscores its significance in the development of next-generation medical tools.

Expansion into Wearable Medical Devices

Role in flexible and lightweight designs

Wearable medical devices have gained popularity due to their potential to monitor and manage health conditions in real time. FEP heat shrink tubing plays a vital role in the design of these devices. Its flexibility allows it to conform to various shapes and sizes, enabling the creation of lightweight and ergonomic wearables.

The tubing's durability ensures that wearable devices can withstand daily use without compromising performance. Its chemical resistance protects internal components from environmental factors, extending the lifespan of these devices. By supporting the development of flexible and lightweight designs, FEP tubing contributes to the growing adoption of wearable medical technologies.

Applications in monitoring and diagnostic tools

FEP heat shrink tubing has expanded its applications to include monitoring and diagnostic tools. Its biocompatibility ensures safe contact with the skin, making it suitable for wearable sensors and diagnostic patches. These devices rely on the tubing's protective properties to maintain functionality in various conditions.

The tubing's transparency and flexibility enhance the usability of monitoring tools, allowing them to provide accurate and reliable data. This capability supports the growing demand for real-time health monitoring solutions, positioning FEP tubing as a key material in the advancement of wearable medical devices.

Challenges and Opportunities

Production Costs and Scalability

Balancing innovation with affordability

The production of FEP heat shrink tubing often involves high-purity raw materials, which significantly increases costs. Manufacturers face the challenge of balancing the need for innovation with affordability. Advanced production techniques, such as in-house tooling and processing, have proven effective in reducing costs. For instance, these methods have successfully lowered expenses for square tubing while meeting customer specifications. However, fluctuations in the supply chain and price volatility can disrupt profitability. Companies must adopt efficient sourcing strategies and explore cost-effective manufacturing solutions to remain competitive.

Challenges in scaling production for high demand

Scaling production to meet the growing demand for FEP tubing presents another challenge. Technological limitations in production processes can lead to inefficiencies, such as inconsistent shrinkage rates and difficulties in achieving precise specifications. These issues result in material waste and increased operational costs. Collaborative ventures between manufacturers and technology developers offer a potential solution. By working together, they can enhance production techniques, reduce inefficiencies, and meet the rising demand for FEP tubing in applications like fluid delivery systems and minimally invasive devices.

Regulatory and Compliance Hurdles

Meeting stringent medical device standards

The medical industry imposes strict regulatory requirements on materials used in device manufacturing. FEP heat shrink tubing must comply with standards such as ISO 10993 for biocompatibility. Meeting these regulations ensures patient safety but also adds complexity to the production process. Manufacturers must invest in rigorous testing and quality assurance to meet these standards. This commitment not only guarantees compliance but also builds trust among healthcare providers and patients.

Navigating global regulatory landscapes

Global markets introduce additional challenges due to varying regulatory frameworks. Manufacturers must navigate diverse compliance requirements across regions, which can delay product launches and increase costs. For example, achieving approval in one country does not guarantee acceptance in another. Companies must develop robust regulatory strategies to address these differences. Partnering with local experts and leveraging customization options can streamline the approval process and facilitate market entry.

Future Potential and Innovations

Integration with smart medical devices

The integration of FEP heat shrink tubing with smart medical devices represents a significant opportunity. These devices, equipped with sensors and advanced technologies, rely on durable and flexible materials for optimal performance. FEP tubing provides the necessary insulation and protection for sensitive components, ensuring reliability in applications such as fluid delivery systems. Its transparency and biocompatibility further enhance its suitability for smart medical technologies. This integration supports the development of innovative solutions that improve patient care and operational efficiency.

Opportunities in personalized medicine

Personalized medicine is reshaping healthcare by tailoring treatments to individual patients. FEP heat shrink tubing plays a crucial role in this transformation by enabling the creation of customized medical devices. Its adaptability allows manufacturers to design tools that meet specific patient needs, such as catheters for unique anatomical structures. The tubing's compatibility with advanced imaging technologies also supports precise diagnostics and targeted therapies. By embracing customization, manufacturers can unlock new opportunities in the growing field of personalized medicine.

Market Outlook

Growth Trends in the Medical Device Industry

Increasing demand for minimally invasive solutions

The medical device industry continues to experience robust growth, driven by the rising preference for minimally invasive procedures. These techniques reduce recovery times and improve patient outcomes, making them a cornerstone of modern healthcare. FEP heat shrink tubing plays a pivotal role in this trend by enabling the development of compact and precise instruments. Its flexibility and biocompatibility make it an essential material for catheters, guide wires, and other tools used in these procedures.

The global market for FEP heat shrink medical tubing reflects this demand. In 2023, the market size reached $131.8 million and is projected to grow to $210.3 million by 2030, with a compound annual growth rate (CAGR) of 6%. This steady expansion underscores the increasing reliance on advanced materials to support minimally invasive solutions. As healthcare providers continue to adopt these techniques, the demand for FEP tubing is expected to rise significantly.

Rising adoption of advanced materials

The adoption of advanced materials like FEP has transformed the medical device landscape. Its unique properties, including chemical inertness, high-temperature resistance, and transparency, make it ideal for a wide range of applications. These attributes have positioned FEP tubing as a preferred choice for manufacturers aiming to enhance the performance and reliability of their products.

The broader FEP tubing market also demonstrates strong growth potential. Valued at $1.2 billion in 2022, it is projected to reach $2.1 billion by 2030, growing at a CAGR of 7.9%. This growth highlights the increasing investment in innovative materials that meet the stringent requirements of the medical industry. As the sector evolves, the adoption of FEP tubing will likely expand into new applications, further driving market growth.

Investment Opportunities in FEP Heat Shrink Tubing

Potential for innovation-driven growth

The FEP heat shrink tubing market offers significant opportunities for innovation-driven growth. Manufacturers are continually developing thinner, more durable, and biocompatible tubing to meet the evolving needs of the medical industry. Innovations such as Junkosha's 1.8:1 shrink ratio Translucent PHST and Thin Wall FEP HST exemplify the potential for groundbreaking advancements in this field.

The market's projected growth supports this innovation. By 2029, the FEP heat shrink medical tubing market is expected to reach $208 million, growing at a CAGR of 7.4%. This trajectory highlights the potential for companies to capitalize on emerging technologies and expand their product portfolios. Investments in research and development will likely yield high returns as the demand for advanced medical devices continues to rise.

Expanding applications in emerging markets

Emerging markets present a lucrative opportunity for the FEP heat shrink tubing industry. Regions with growing healthcare infrastructure and increasing access to medical technologies are driving demand for advanced materials. The versatility of FEP tubing makes it suitable for a wide range of applications, from minimally invasive procedures to wearable medical devices.

The global market's expansion reflects this trend. With a CAGR of 6.9% from 2022 to 2030, the FEP heat shrink tubing sector is poised for substantial growth in both developed and developing regions. Companies that focus on tailoring their products to meet the specific needs of these markets can unlock new revenue streams. By addressing regional healthcare challenges, manufacturers can establish a strong foothold in these high-growth areas.

FEP heat shrink tubing continues to redefine the medical industry with its remarkable advancements. Improved biocompatibility ensures safer patient-facing applications, while thinner wall designs enhance flexibility and precision in minimally invasive procedures. Enhanced durability extends the lifespan of medical devices, reducing costs and improving reliability. These innovations position FEP tubing as a cornerstone material in modern healthcare.

The growing role of FEP tubing in minimally invasive techniques, wearable devices, and advanced imaging technologies highlights its versatility. Continued innovation, driven by regulatory compliance and emerging technologies, will unlock new opportunities, creating solutions that meet evolving medical demands and improve patient outcomes.

FAQ

What are the popular types of FEP tubing products available in the market?

FEP tubing products cater to diverse industries due to their exceptional properties. In the medical field, fep heat shrink tube is widely used for applications like catheters, guide wires, and insulation for high-temperature cables. Laboratories rely on FEP tubing for critical processes such as chromatography and auto-sampling. Its chemical resistance and transparency make it ideal for drug delivery systems and other advanced medical devices. The medical tubing market also benefits from FEP's versatility, offering solutions for minimally invasive procedures and diagnostic tools.

How does FEP heat shrink tubing enhance medical device performance?

FEP heat shrink tubing improves medical device performance by providing insulation, protection, and flexibility. Its chemical inertness ensures compatibility with sterilization processes, while its transparency allows for precise monitoring of internal components. The tubing's biocompatibility minimizes risks during patient-facing applications. These features make it indispensable in the medical tubing market, especially for devices requiring durability and precision.

Why is FEP heat shrink tubing preferred for minimally invasive procedures?

Minimally invasive procedures demand compact and precise instruments. FEP heat shrink tubing supports these requirements with its thin wall designs and flexibility. It conforms to intricate device structures, enabling smooth navigation through narrow anatomical pathways. Its low coefficient of friction enhances maneuverability, making it a preferred choice in the medical tubing market for applications like endoscopy and laparoscopy.

What advancements have been made in FEP heat shrink tubing technology?

Recent advancements in FEP heat shrink tubing technology include innovations like Junkosha's 1.8:1 shrink ratio Translucent PHST and Thin Wall FEP HST. These developments address the need for thinner, more durable, and customizable tubing. The medical tubing market has embraced these innovations, which enhance device performance and support a wide range of customization for medical applications.

How does FEP tubing contribute to patient safety?

FEP tubing ensures patient safety through its biocompatibility and resistance to harsh sterilization methods. It minimizes the risk of adverse reactions during medical procedures. Additionally, its durability and reliability reduce the likelihood of device failure, aligning with the stringent safety standards of the medical tubing market.

Can FEP heat shrink tubing be used in wearable medical devices?

Yes, FEP heat shrink tubing is increasingly used in wearable medical devices. Its flexibility and lightweight design make it suitable for applications like monitoring and diagnostic tools. The tubing's chemical resistance protects internal components, ensuring long-term functionality. This adaptability has expanded its role in the medical tubing market, particularly in real-time health monitoring solutions.

What role does FEP tubing play in drug delivery systems?

FEP tubing plays a crucial role in drug delivery systems by providing a chemically inert and transparent conduit for precise medication administration. Its compatibility with sensitive drugs ensures accurate delivery without contamination. The medical tubing market relies on FEP tubing for its reliability and efficiency in these critical applications.

How does the medical tubing market benefit from FEP heat shrink tubing?

The medical tubing market benefits from FEP heat shrink tubing's unique properties, including high-temperature resistance, chemical inertness, and biocompatibility. These attributes support the development of advanced medical devices, such as catheters, guide wires, and wearable technologies. The tubing's versatility and durability drive innovation and growth within the industry.

What challenges exist in scaling FEP heat shrink tubing production?

Scaling FEP heat shrink tubing production poses challenges like maintaining consistent quality and meeting high demand. Advanced manufacturing techniques and collaborative efforts between manufacturers and technology developers help address these issues. The medical tubing market continues to seek efficient solutions to balance innovation with affordability.

How does FEP tubing support the future of personalized medicine?

FEP tubing supports personalized medicine by enabling the creation of customized medical devices tailored to individual patient needs. Its adaptability allows manufacturers to design tools for unique anatomical structures. The tubing's compatibility with advanced imaging technologies further enhances its role in targeted therapies, solidifying its importance in the evolving medical tubing market.

See Also

The Importance of Ultra-Thin PET Tubing in Healthcare

New Developments in PTFE Liners for Medical Applications

Future Innovations Transforming PTFE Liners in Medicine