What is FDA Compliant PET Heat Shrink Tubing for Medical Devices

You use FDA compliant PET heat shrink for medical devices. It helps keep patient care safe and works well. This tubing is made from PET material. It gives strong insulation and protects medical tools. You help keep patients safe by using this tubing. It stops electrical problems, keeps important parts clean, and protects devices from harm. These things help medical equipment work safely everywhere.

Stops electrical problems in devices

Lowers the chance of germs in medical places

Protects from hits and scratches, keeping patients safe

Key Takeaways

FDA compliant PET heat shrink tubing keeps medical devices safe. It stops electrical problems and lowers the risk of germs. PET material is tough, clear, and does not get damaged by chemicals. This makes it good for medical use that lasts a long time. To install PET tubing, you heat it so it shrinks around devices. This gives good insulation and keeps devices safe. PET tubing must meet FDA and USP Class VI rules. These rules help make sure medical devices are safe and work well. PET tubing can be made in special ways to fit different needs. This helps medical devices get what they need fast.

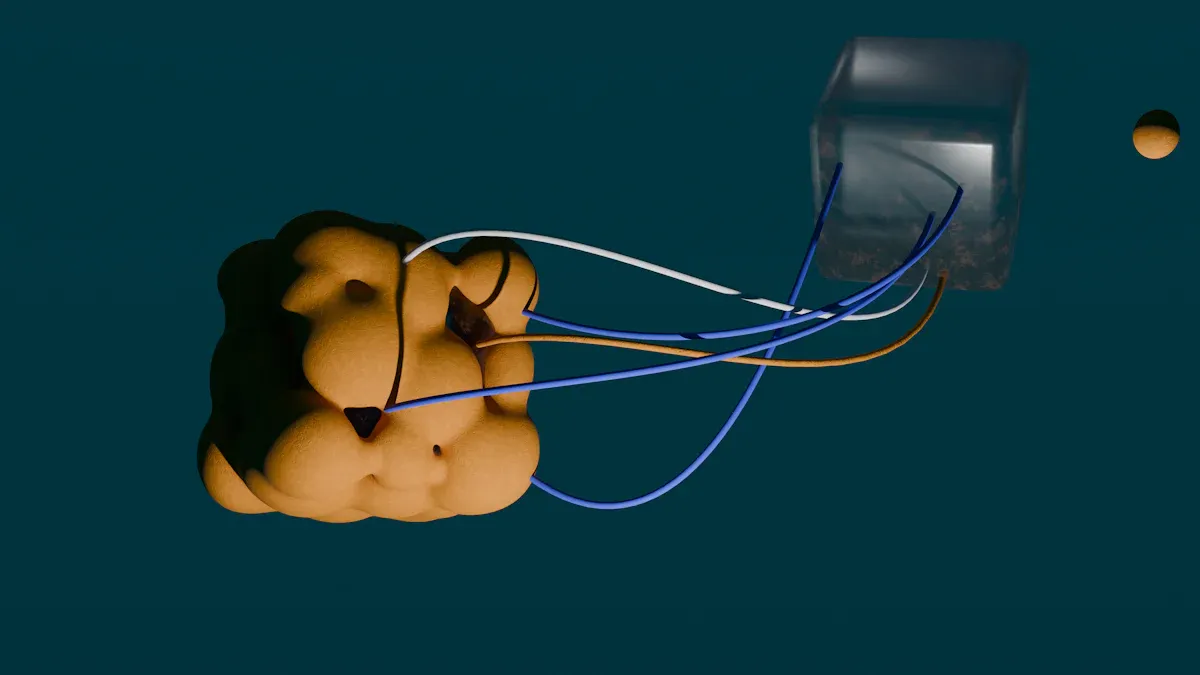

PET Heat Shrink Tubing in Medical Devices

Material Properties of PET

People pick PET heat shrink tubing for medical devices because it has special benefits. PET means polyethylene terephthalate. This material is very strong and keeps its shape well. PET tubing is clear, tough, and works well for medical tools. It does not get damaged by many chemicals, so your devices last longer.

Here is a simple table to compare PET heat shrink tubing with other materials:

Advantage | PET Heat Shrink Tubing | Other Materials (e.g., FEP) |

|---|---|---|

Mechanical Strength | High | Moderate |

Dimensional Stability | Excellent | Variable |

Cost-Effectiveness | Economical | Higher |

Chemical Resistance | Good | Limited |

Optical Clarity | Excellent | Limited |

PET heat shrink tubing is strong, clear, and saves money. You can see through PET tubing, so it is easy to check your devices. This helps keep things safe and working well.

How Heat Shrink Tubing Works

PET heat shrink tubing starts bigger than the part you want to cover. You put the tubing over your device. When you heat it, the tubing gets smaller and fits tightly. Most PET heat shrink tubing shrinks to half or a quarter of its size. You usually heat it to about 150°C (302°F), but it can shrink between 275°F and 350°F. This makes a tight, safe cover for your medical devices.

PET heat shrink tubing keeps printed circuit boards safe in medical monitors.

It fits tightly around important parts, which helps with electrical safety.

The tubing does not get ruined by cleaning chemicals, so it lasts a long time.

Insulation and Protection for Devices

Medical devices need strong insulation and protection. PET heat shrink tubing gives both. It has high dielectric strength, so it stops electrical problems. PET tubing keeps your devices safe in many places.

Property | Description |

|---|---|

Dielectric Strength | High dielectric strength stops electrical dangers and keeps things safe. |

Durability | Strong material lasts a long time and keeps insulation working. |

Biocompatibility | Safe for medical use and protects important parts. |

PET heat shrink tubing is used for medical wire insulation in things like defibrillators and imaging machines. The tubing blocks electrical currents and keeps devices safe from scratches and bumps. FDA registered PET shrink tubing follows strict rules, so your medical devices stay safe. You can trust PET tubing for medical heat shrink and heat shrinkable tubing jobs. When you pick FDA registered PET shrink tubing, you help keep your devices safe and working well.

FDA Compliance and Medical Standards

What FDA Compliance Means

You have to follow strict rules when picking fda compliant pet heat shrink for medical devices. FDA compliance means the tubing meets safety and health rules. These rules help protect patients, customers, and workers. You can trust fda compliant tubing because it lowers the chance of recalls and problems. You also get clear records to help with U.S. and world regulations. Medical device makers use these rules to keep devices safe and working.

Tip: Always make sure your tubing follows fda regulations before using it in medical devices.

FDA compliance gives you:

Trust in the safety of your devices

Less risk of recalls and problems

Good records for rules

Safety for patients and workers

Achieving FDA and USP Class VI Standards

You need to meet special rules to use tubing in medical devices. USP Class VI certification is very important. You must test the tubing with three main checks: Intracutaneous Injection, Systemic Toxicity, and Implant tests. These tests use animals like mice or rabbits. You watch for reactions to make sure the tubing is safe. You cannot just use the material’s certification for the final product. You must test each kind of tubing by itself.

Test Name | Purpose | How It Works |

|---|---|---|

Intracutaneous Injection | Checks for skin problems | Injects tubing extract into animals |

Systemic Toxicity | Checks for bad effects in the body | Watches animals for reactions |

Implant Test | Checks for safety inside the body | Puts tubing in animals |

You need these tests to show your tubing is safe for medical devices. Meeting USP Class VI and FDA rules helps you follow the law and keep your devices safe.

Additional Regulatory Approvals

You also need to look at other rules when picking tubing for medical devices. RoHS limits bad substances in electrical and electronic things. This keeps devices safe for people and the planet. FDA CFR 177.2600 sets rules for what materials can be used, how much can be taken out, and how to test. USP rules make sure your tubing is pure, strong, and always the same. REACH and NSF rules add more safety checks for medical devices.

Here is a quick guide to important standards:

Standard | What It Covers | Why It Matters for Medical Devices |

|---|---|---|

FDA | Safety, health, and records | Protects patients and follows rules |

USP Class VI | Purity, toxicity, and biocompatibility | Makes sure tubing is safe for medical use |

RoHS | Limits bad substances | Keeps devices safe and green |

REACH | Chemical safety and planet protection | Adds safety for workers and patients |

NSF | Public health and safety | Makes sure products meet tough rules |

You must follow these strict rules to keep your devices safe and trusted. These standards help you avoid problems and keep your products reliable in the medical field.

Note: Following all rules is important for safety and compliance.

Key Features and Benefits of PET Heat Shrink Tubing

Biocompatibility and Safety

You want medical devices to be safe for everyone. PET heat shrink tubing meets tough safety rules. You can trust this tubing because it passes many tests. These tests check for skin problems, allergies, and if it is toxic. PET tubing follows ISO 10993 and USP Class VI rules. You can see how these tests work in the table below:

Test Type | Description |

|---|---|

ISO 10993 Compliance | Makes sure materials are safe for the body. It checks for skin problems and allergies. |

USP Class VI Certification | Looks at safety with injections, toxicity checks, and implant tests. |

PET heat shrink tubing helps keep patients safe. It lowers the chance of germs and electrical problems. You protect important parts and meet FDA rules for your devices.

Durability and Performance

You need tubing that lasts a long time. PET heat shrink tubing is very strong. It can last over 20 years in medical devices. This tubing helps your devices stay strong and work well. You get good quality every time you use FDA registered pet shrink tubing. The table below shows how PET tubing helps with safety and quality:

Benefit | Contribution to Safety and Compliance |

|---|---|

Structural reinforcement | Makes devices less likely to break, keeping patients safe. |

Reliable insulation | Lowers the chance of germs and electrical problems. |

Long-lasting durability | Makes sure devices work well and help patients. |

The tubing’s dielectric strength is great for high-voltage parts. It stops electrical problems and keeps the device safe.

Sterilization Compatibility

You need to clean medical devices many times. PET heat shrink tubing stays strong after cleaning. You can use heat, radiation, or chemicals to clean it. PET tubing does not break and keeps its quality. The table below shows which cleaning methods work with PET tubing:

Sterilization Method | Compatibility with PET Tubing |

|---|---|

Heat-Based Sterilization | PET tubing works with autoclaving and stays strong after cleaning. |

Radiation Sterilization | PET tubing works well with gamma and e-beam cleaning. It keeps its properties. |

Chemical Sterilization | PET tubing does not get ruined by hydrogen peroxide or ethylene oxide. |

PET heat shrink tubing helps you follow safety and quality rules in the medical field.

Customization and Short Lead Times

You can change PET heat shrink tubing for your devices. You pick shrink ratios, thickness, and adhesive linings. PET tubing can shrink up to 70% and still stay strong. You can add printing or marks for easy labels. FDA registered pet shrink tubing ships fast. Medeologix sends custom orders in only 3 weeks. You get clear PET shrink tubing quickly, so you meet your deadlines and keep devices safe.

PET heat shrink tubing gives you choices, good quality, and follows rules. You keep patients safe and meet regulations with every order. You help devices work well and stay safe in the medical field.

Applications of FDA Compliant PET Heat Shrink for Medical Devices

Use in Wearable and Implantable Devices

You find pet heat shrink tubing in many wearable devices. It helps keep devices safe and working well. You see it in fitness trackers, glucose monitors, and pacemakers. These devices need strong insulation and protection. Pet heat shrink tubing gives both. It helps stop electrical leaks and blocks germs to keep patients safe.

Fitness trackers

Glucose monitors

Pacemakers

Pet heat shrink tubing fits tightly around small parts. It keeps out water, sweat, and dirt. You can trust this tubing to last a long time. The table below shows how pet heat shrink tubing helps your devices:

Property | Benefit |

|---|---|

Exceptional electrical insulation | Stops electrical leaks and keeps devices working safely. |

Resistance to environmental stressors | Handles moisture, chemicals, and heat, so devices keep working. |

Biocompatibility | Makes sure the tubing does not hurt human tissue. |

Compact design | Fits tightly to parts and helps devices last longer. |

Examples in Vascular and Electrophysiology Devices

You use pet heat shrink tubing in devices for blood vessels and heart problems. It is also used in devices for treating tumors and checking heart signals. These devices need strong insulation and protection. Pet heat shrink tubing gives great electrical insulation. It stops short circuits and lowers shock risks. This helps keep patients safe during every procedure.

Pet heat shrink tubing keeps working under heat and stress.

It helps meet medical standards and makes devices more reliable.

Fda compliant pet heat shrink for medical devices helps you follow strict rules.

You also use pet heat shrink tubing in devices for treating tumors. You need tubing with high dielectric strength, thermal stability, and chemical resistance. The table below shows what you should look for:

Property | Description |

|---|---|

High Dielectric Strength | Gives strong electrical insulation with a dielectric strength over 4,000 V/mil. |

Thermal Stability | Works at high temperatures up to 150°C (302°F) and can handle short bursts up to 200°C (392°F). |

Chemical Resistance | Resists oils, solvents, and harsh chemicals for long-lasting use. |

Mechanical Strength | Has high strength and resists scratches for tough jobs. |

Precision Shrinkage | Shrinks evenly when heated and fits tightly around parts. |

Selecting the Right Tubing for Medical Applications

You need to pick the right pet heat shrink tubing for your medical devices. Look for tubing that meets fda and medical standards. Fda registered pet shrink tubing gives the best safety and quality. You want tubing that fits tightly, lasts long, and keeps patients safe. Always check for high dielectric strength, thermal stability, and chemical resistance. Fda compliant pet heat shrink for medical devices helps you meet all these needs.

Tip: Pick fda registered pet shrink tubing for fast shipping and great quality.

You keep your devices safe and working well by using the right pet heat shrink tubing. You protect patients and help your medical devices work better every time.

You help keep patients safe when you pick FDA compliant PET heat shrink tubing for medical devices. This tubing makes devices work well and helps doctors do their jobs better. There are many good things about it:

PET tubing is safe for people to touch.

It stays strong and keeps its shape after lots of cleaning.

The tubing helps new surgical tools work exactly right.

You should always look at important standards before you choose tubing:

Standard | Purpose |

|---|---|

ASTM D2671 | Checks that PET tubing is strong and safe. |

SAE AS23053 | Gives rules for how tubing works in different situations. |

Tests if tubing is safe for medical use. | |

FDA rules | Makes sure tubing follows safety laws for medical devices. |

ISO 13485 | Keeps quality high when making medical devices. |

USP Class VI | Shows materials are safe for people and do not hurt anyone. |

You make the best choice for safety, good performance, and patient care when you think about all the standards and what your device needs.

FAQ

What is PET heat shrink tubing used for in medical devices?

You use PET heat shrink tubing to insulate wires and protect sensitive parts. It helps keep medical devices safe from electrical problems, germs, and damage during use.

How do you install PET heat shrink tubing?

You slide the tubing over the part you want to cover. You heat it with a special tool. The tubing shrinks and fits tightly, giving strong protection.

Can PET heat shrink tubing handle sterilization?

You clean PET heat shrink tubing with heat, chemicals, or radiation. It stays strong and keeps its shape after many cleaning cycles. You can trust it for repeated sterilization.

Is PET heat shrink tubing safe for patients?

You get safety with PET heat shrink tubing. It passes strict tests for skin contact and toxicity. You can use it in medical devices without worrying about patient safety.

How do you choose the right PET heat shrink tubing?

You look for tubing that fits your device size and meets safety standards. You check for high dielectric strength, durability, and compatibility with cleaning methods.

See Also

The Importance of Ultra-Thin PET Tubing in Healthcare

New Developments in FEP Heat Shrink Tubing for Healthcare

FEP Heat Shrink Tubing Producers Revolutionizing Medical Equipment