What Makes Extruded PTFE Liners Superior for Medical Devices

Extruded PTFE liners have become indispensable in the medical field due to their exceptional properties. These liners exhibit high yield strength, ensuring reliability in critical applications like cardiovascular surgeries. Their chemical resistance prevents degradation when exposed to bodily fluids, while their low friction coefficient enhances patient comfort during procedures. Medical grade PTFE liners also maintain structural integrity under extreme conditions, making them ideal for demanding environments. Additionally, their biocompatibility ensures safety, reducing the risk of adverse reactions. These qualities make extruded PTFE liners the preferred choice for advancing medical device performance and reliability.

Key Takeaways

Extruded PTFE liners are strong, making them reliable for surgeries.

They resist chemicals, so they don’t break down in the body.

PTFE liners are safe for the body and won’t cause bad reactions.

They can be customized for special uses, improving medical device designs.

Understanding PTFE and Its Role in Medical Applications

What Is PTFE?

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer known for its exceptional chemical resistance, low friction, and thermal stability. This material, often referred to as a "non-stick" polymer, is widely used in industries requiring high-performance materials. In medical applications, PTFE tubing and liners are particularly valued for their ability to maintain structural integrity under extreme conditions. Its unique molecular structure, composed of carbon and fluorine atoms, provides unparalleled durability and inertness, making it a cornerstone material in healthcare technology.

Why PTFE Is Essential for Medical Devices

PTFE plays a critical role in medical devices due to its unique properties. Its biocompatibility ensures safe interaction with human tissues and fluids, making it ideal for implantable devices. The material's smooth surface minimizes biological material buildup, reducing infection risks. Additionally, PTFE's low friction facilitates smoother insertion and navigation in devices like catheters and guidewires. Its chemical inertness prevents reactions with bodily fluids or medications, ensuring device integrity. Furthermore, PTFE withstands sterilization processes, maintaining its properties across a wide temperature range. These characteristics make PTFE indispensable in advancing medical device safety and performance.

Common Applications of PTFE in Healthcare

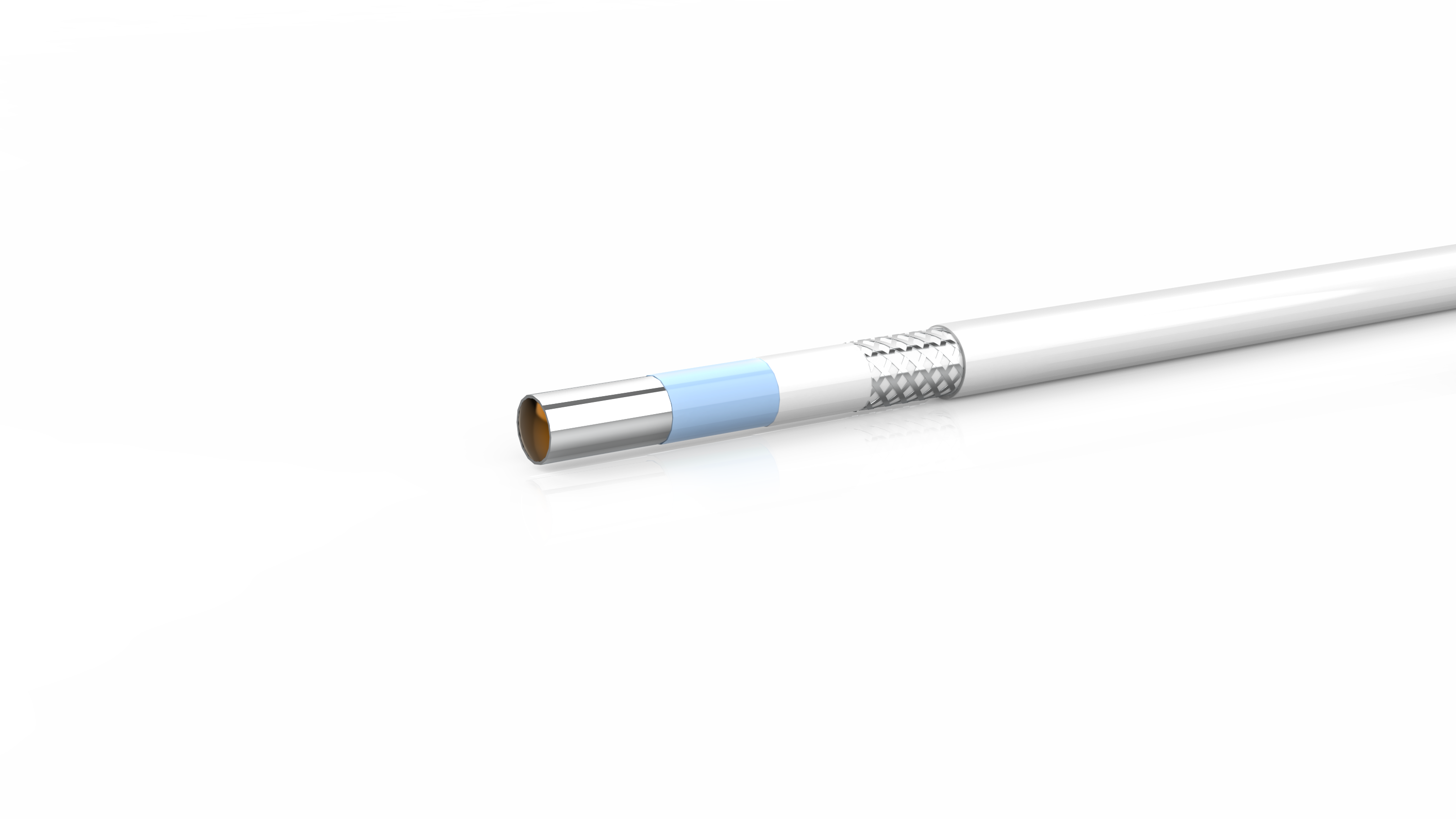

PTFE is widely used in various medical devices. Common applications of PTFE include catheters, where its low friction improves patient comfort.

PTFE tubing also plays a vital role in fluid transfer systems, ensuring precision and reliability in critical procedures. These diverse applications of PTFE highlight its versatility and importance in modern healthcare.

Unique Properties of Extruded Medical Grade PTFE Liners

Biocompatibility and Safety

Medical-grade PTFE liners excel in biocompatibility, making them a safe choice for healthcare applications. Their chemically inert nature prevents adverse reactions with bodily tissues or fluids, ensuring compatibility with human physiology. Unlike other materials, they do not cause allergic responses or complications, even during prolonged use. The smooth surface of these liners minimizes bacterial adhesion, reducing the risk of infections in sterile environments. Furthermore, their inertness prevents interactions with medications, preserving therapeutic efficacy. These qualities make extruded PTFE liners indispensable in medical devices requiring high safety standards.

Precision and Dimensional Stability

Extruded PTFE liners offer unmatched precision and dimensional stability, critical for advanced medical devices. They maintain structural integrity over extended periods, outperforming materials like silicone, which may degrade under certain conditions. Their chemical resistance ensures reliability when exposed to bodily fluids or medications. The low-friction surface of PTFE liners facilitates smoother catheter navigation, enhancing patient comfort during procedures. Additionally, their ability to withstand extreme temperatures makes them suitable for a wide range of medical applications. Compared to polyurethane or silicone, PTFE liners provide superior durability and performance, ensuring consistent results in dynamic sealing applications.

Durability and Resistance to Wear

The durability of extruded PTFE liners ensures long-lasting performance in demanding medical environments. These liners resist wear and tear, even under continuous use, maintaining their functionality over time. Their chemical resistance protects them from degradation when exposed to harsh substances, such as bodily fluids or sterilization chemicals. The smooth surface of PTFE liners resists bacterial and fungal growth, making them ideal for sterile applications. Their ability to endure extreme temperatures and mechanical stress further enhances their reliability. These properties make extruded PTFE liners a preferred choice for innovative catheter designs and other high-performance medical devices.

Chemical and Thermal Resistance

Extruded PTFE liners exhibit exceptional chemical and thermal resistance, making them indispensable in medical applications. Their ability to withstand exposure to harsh chemicals ensures long-term reliability in environments where bodily fluids, medications, and sterilization agents are present. Unlike other materials, PTFE liners do not degrade or react chemically, preserving their structural integrity and functionality over time.

Thermal resistance is another critical property of extruded PTFE liners. These liners maintain their performance across a wide temperature range, from cryogenic conditions to extreme heat. This stability allows them to endure sterilization processes, such as autoclaving, without compromising their physical properties. Medical devices incorporating PTFE liners can operate reliably in both high-temperature surgical environments and low-temperature storage conditions.

The combination of chemical and thermal resistance enhances the versatility of PTFE liners. For instance, in catheter applications, these properties ensure smooth operation even when exposed to fluctuating temperatures or aggressive cleaning agents. Similarly, in surgical instruments, PTFE liners provide a protective barrier that resists wear and maintains precision during repeated use.

Note: The durability of PTFE liners under chemical and thermal stress reduces the need for frequent replacements, contributing to cost-effectiveness in medical device manufacturing.

In comparison to alternative materials, such as silicone or polyurethane, PTFE liners consistently outperform in demanding conditions. Their superior resistance to chemical exposure and thermal extremes ensures that medical devices meet stringent safety and performance standards. These qualities make extruded PTFE liners a trusted choice for advancing healthcare technology.

Comparing Extruded PTFE Liners to Other Types

Extruded vs. Ram-Extruded PTFE Liners

Extruded PTFE liners outperform ram-extruded PTFE tubing in several critical aspects. The differences between PTFE and RPTFE stem from their manufacturing processes, which directly influence their performance.

Yield Strength: Extruded PTFE liners exhibit higher yield strength, enabling them to endure stress without failure. This makes them ideal for demanding medical applications, such as cardiovascular catheters.

Manufacturing Process Impact: The free extrusion process optimizes molecular orientation, enhancing the material's structural integrity and overall performance.

Applications: Ram-extruded PTFE tubing, while suitable for less demanding uses, lacks the robustness required for high-stress environments.

These distinctions highlight the advantages of PTFE liners in medical devices, where precision and reliability are paramount.

Extruded vs. Film-Cast PTFE Liners

The differences between extruded and film-cast PTFE liners become evident when comparing their performance in medical applications. The following table summarizes these differences:

Feature | Extruded PTFE Liners | Film-Cast PTFE Liners |

|---|---|---|

Yield Strength | Higher | Lower |

Molecular Orientation | Optimized | Random |

Performance in Medical Use | Superior | Inferior |

Extruded PTFE liners provide superior yield strength and optimized molecular orientation, ensuring consistent performance in critical medical devices. Film-cast liners, with their random molecular structure, fall short in applications requiring high precision and durability.

Performance in Medical Applications of PTFE Liners

Medical-grade PTFE liners excel in several performance metrics, making them indispensable in healthcare. The table below outlines key metrics:

Performance Metric | Description |

|---|---|

Reduced Friction | Medical-grade PTFE liners significantly reduce friction, providing a smoother glide for catheters during insertion and navigation. |

Improved Durability | These liners exhibit exceptional durability, ensuring that catheters maintain their structural integrity over extended periods. |

Superior Biocompatibility | Medical-grade PTFE liners are chemically inert, preventing adverse reactions with bodily tissues or fluids, ensuring safety for prolonged use. |

The advantages of PTFE liners, such as reduced friction and enhanced durability, ensure optimal performance in medical devices. Their chemical resistance and biocompatibility further solidify their role in advancing healthcare technology.

Note: While extruded PTFE liners dominate in performance, understanding the disadvantages of RPTFE and the limitations of alternative materials like FEP and PFA is essential for selecting the right liner for specific applications.

Advantages of Extruded PTFE Liners for Medical Devices

Meeting Stringent Medical Standards

Extruded PTFE liners meet the rigorous standards required for medical applications. Their chemically inert nature ensures compatibility with bodily fluids and medications, reducing the risk of adverse reactions. This stability aligns with the high expectations of the healthcare industry, where safety and reliability are paramount. Medical grade PTFE liners also comply with stringent biocompatibility regulations, making them suitable for use in implantable devices and other critical applications. These liners undergo extensive testing to ensure they meet or exceed industry benchmarks, providing healthcare professionals with confidence in their performance.

Enhancing Device Performance and Longevity

Extruded PTFE liners significantly enhance the performance and lifespan of medical devices. Their low-friction surface allows catheters to glide smoothly during insertion, reducing tissue damage and improving procedural precision. The exceptional durability of these liners ensures that devices maintain structural integrity over time, minimizing the need for frequent replacements. Additionally, their biocompatibility prevents adverse reactions with bodily tissues, ensuring safe and prolonged use. These qualities make extruded PTFE liners an indispensable component in high-performance medical devices.

Key benefits include:

Reduced friction for smoother catheter navigation.

Enhanced durability, leading to fewer replacements and lower costs.

Biocompatibility, ensuring safety during extended use.

Customization and Versatility for Specialized Applications

Extruded PTFE liners offer unparalleled customization options, making them ideal for specialized medical applications. Manufacturers can tailor wall thicknesses, diameters, and lengths to meet specific requirements. This flexibility allows for the development of catheters optimized for vascular, urological, and neurological procedures. Thin-walled PTFE liners enhance catheter flexibility, enabling navigation through complex anatomical pathways.

Examples of specialized applications include:

Tailored specifications for unique medical needs.

Optimized catheter designs for interventional procedures.

Biomaterials for artificial blood vessels and heart repair membranes.

These liners also benefit interventional catheters, such as microcatheters and guide catheters, by providing ultra-thin walls and excellent lubricity. Their non-toxic and immune-resistant properties make them suitable for biomaterials, ensuring stable treatment outcomes. The versatility of extruded PTFE liners continues to drive innovation in healthcare technology.

Cost-Effectiveness in High-Performance Medical Devices

Extruded PTFE liners offer significant cost advantages for high-performance medical devices. Their exceptional durability reduces the frequency of replacements, lowering long-term maintenance expenses. Unlike materials such as rptfe or fep, extruded PTFE liners maintain their structural integrity under extreme conditions, ensuring consistent performance over time. This reliability minimizes device failures, which can lead to costly repairs or replacements.

The manufacturing process of extruded PTFE liners also contributes to cost savings. The optimized molecular orientation achieved during extrusion enhances material efficiency, reducing waste. Compared to rptfe, which often requires additional processing steps, extruded PTFE liners streamline production, resulting in lower manufacturing costs. Similarly, fep liners, while useful in some applications, lack the robustness of extruded PTFE liners, leading to higher lifecycle costs.

Healthcare providers benefit from the cost-effectiveness of extruded PTFE liners through improved device longevity. For example, catheters with extruded PTFE liners require fewer replacements due to their resistance to wear and chemical degradation. This durability translates to fewer disruptions in patient care and reduced operational costs for medical facilities. Additionally, the biocompatibility of these liners eliminates the need for expensive coatings or treatments, further enhancing their value.

In comparison to ptfe and fep alternatives, extruded PTFE liners consistently deliver superior performance at a lower total cost of ownership. Their ability to withstand harsh environments and maintain functionality over extended periods makes them a preferred choice for cost-conscious manufacturers and healthcare providers. By investing in extruded PTFE liners, the medical industry achieves a balance between performance and affordability, driving innovation while managing expenses effectively.

Extruded PTFE liners stand out as the optimal choice for medical devices due to their precision, biocompatibility, and compliance with stringent healthcare standards. Their exceptional properties, such as chemical resistance and low friction, ensure enhanced safety and performance in critical applications. These liners are increasingly vital in advanced medical technologies, including microcatheters, where precision and reliability are paramount.

Key factors driving their continued relevance include:

Integration into minimally invasive devices to improve navigation and reduce infection risks.

Advancements in extrusion techniques enabling ultra-thin walls and superior durability.

Growing demand for innovative medical solutions due to aging populations and chronic diseases.

As medical technology evolves, extruded PTFE liners will remain indispensable, supporting the development of safer, more efficient healthcare devices.

FAQ

What makes extruded PTFE liners different from other materials?

Extruded PTFE liners stand out due to their superior chemical resistance, biocompatibility, and low friction. These properties ensure reliable performance in medical devices, even under extreme conditions. Their precision and durability make them a preferred choice for advanced healthcare applications.

Are extruded PTFE liners safe for implantable devices?

Yes, extruded PTFE liners are highly biocompatible and chemically inert. These qualities ensure they do not react with bodily tissues or fluids, making them safe for use in implantable medical devices. Their smooth surface also minimizes infection risks.

How do extruded PTFE liners improve catheter performance?

Extruded PTFE liners reduce friction, allowing catheters to glide smoothly during insertion. This minimizes tissue damage and enhances procedural accuracy. Their durability ensures consistent performance over time, making them ideal for high-precision medical applications.

Can extruded PTFE liners withstand sterilization processes?

Yes, extruded PTFE liners exhibit excellent thermal resistance, allowing them to endure sterilization methods like autoclaving. They maintain their structural integrity and performance even after repeated exposure to high temperatures and harsh cleaning agents.

Why are extruded PTFE liners cost-effective for medical devices?

Their durability reduces the need for frequent replacements, lowering long-term costs. The optimized manufacturing process minimizes waste, further enhancing cost efficiency. These factors make extruded PTFE liners a practical choice for high-performance medical devices.

See Also

The Revolutionary Impact of Medical Grade PTFE Liners

Future Innovations Transforming PTFE Liners in Medical Applications

New Developments Influencing Medical PTFE Liner Technologies