AccuPath PTFE Liners: Elevate Medical Catheters Now

AccuPath etched PTFE liners used in medical catheters redefine the standards for performance in this critical field. Their superior adhesion ensures a secure bond with catheter components, preventing delamination during essential procedures. The liners' biocompatibility minimizes allergic reactions, making them a safe choice for sensitive environments. With a low-friction surface, they facilitate smooth catheter insertion and withdrawal, enhancing patient comfort and reducing tissue damage. AccuPath’s commitment to quality and innovation simplifies selecting the right etched PTFE liner used in medical catheters, offering tailored solutions that meet diverse medical needs. As a trusted source for a good supplier, AccuPath combines durability and longevity with an unmatched supplier reputation and technical support.

Key Takeaways

AccuPath etched PTFE liners stick well to catheters, stopping peeling during use.

These liners are safe for the body and reduce allergic risks, keeping patients protected.

Their smooth surface makes catheters easier to insert and remove, helping patients feel better.

Manufacturers can customize these liners for different medical uses, making them safer and more useful.

What Is an Etched PTFE Liner Used in Medical Catheter Applications?

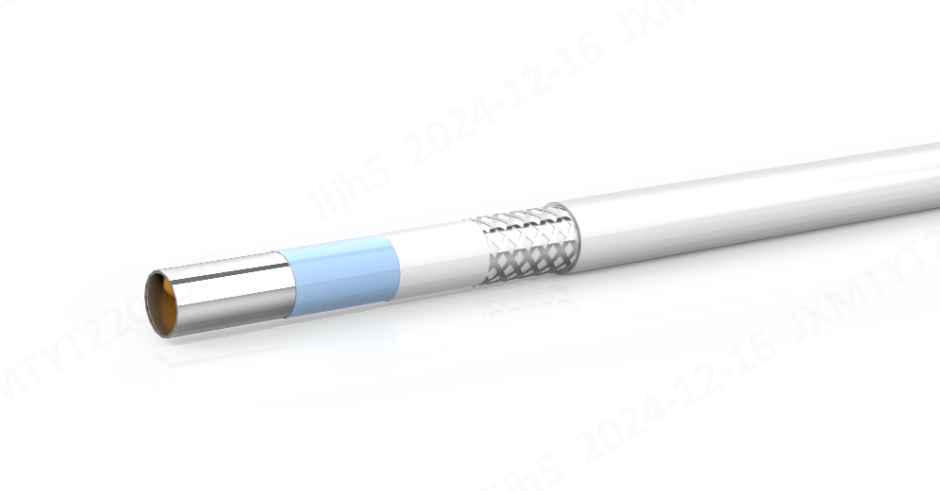

Definition and Purpose of Etched PTFE Liners

Etched PTFE liners are specialized components crafted from polytetrafluoroethylene (PTFE), designed to enhance the performance of medical catheters. These liners feature a smooth, low-friction surface that facilitates seamless catheter insertion and withdrawal, reducing the risk of tissue damage. The etching process modifies the liner's surface, creating a textured layer that improves adhesion to other catheter components. This ensures structural integrity during use, preventing delamination and device failure.

Key characteristics of etched PTFE liners include:

Biocompatibility, which minimizes the risk of infections and adverse reactions.

Durability and wear resistance, enabling reliable performance in demanding medical environments.

Chemical inertness, ensuring stability when exposed to bodily fluids.

These features make etched PTFE liners indispensable in medical applications, where safety and precision are paramount.

How Etching Enhances Adhesion in Medical Applications

Etching technology transforms the surface properties of PTFE liners, increasing their surface energy. This modification allows adhesives to form stronger bonds with the liner, ensuring reliable adhesion between catheter components. In medical applications, this enhanced adhesion is critical. It prevents delamination during procedures, maintaining the catheter's structural integrity and functionality. By ensuring a secure bond, etched PTFE liners contribute to the overall safety and effectiveness of medical devices.

Common Uses of Etched PTFE Liners in Catheters

Etched PTFE liners are integral to a variety of medical catheter applications. Their low-friction surface and strong adhesion make them ideal for:

Minimally invasive procedures, where precision and efficiency are essential.

Cardiovascular interventions, where smooth navigation through delicate pathways is critical.

Devices requiring biocompatibility and durability to ensure patient safety and comfort.

Benefit | Description |

|---|---|

Biocompatibility | Reduces the risk of adverse reactions and infections. |

Durability | Ensures reliable performance in demanding environments. |

Reduced Friction | Enhances patient comfort by minimizing tissue damage. |

Enhanced Adhesion | Prevents delamination, ensuring structural integrity. |

Compliance with Standards | Meets stringent medical regulations for safety and reliability. |

These liners play a pivotal role in improving patient outcomes by ensuring precision, safety, and reliability in critical healthcare settings.

Key Considerations for Selecting a PTFE Etched Liner

Application-Specific Requirements

Compatibility with Catheter Design and Function

Selecting the right PTFE etched liner begins with understanding its intended application. Each medical device has unique requirements, and the liner must align with the catheter's design and function. For example, cardiovascular catheters demand liners with low friction to ensure smooth navigation through delicate pathways. Similarly, devices used in minimally invasive procedures require biocompatibility and bonding precision to enhance patient safety and procedural efficiency. AccuPath’s etched PTFE liners excel in meeting these needs, offering chemical resistance and compatibility with various catheter designs.

Performance in Challenging Conditions

Medical environments often expose devices to extreme conditions, such as high temperatures and repeated sterilization. PTFE etched liners must maintain their integrity under these circumstances. AccuPath ensures its liners deliver exceptional durability and resistance, making them suitable for demanding applications. Their chemically inert nature prevents reactions with bodily fluids, ensuring safety and reliability during use. This resilience enhances the longevity of medical devices, reducing the risk of failure during critical procedures.

Size and Dimensional Precision

Importance of Accurate Measurements

Precision is vital in medical device manufacturing. Even minor deviations in size can compromise a catheter's performance. AccuPath produces etched PTFE liners with ultra-thin walls, ranging from 0.0004" to 0.002". This precision minimizes stiffness in catheter shafts, improving flexibility and maneuverability. The low-friction surface further enhances procedural accuracy, allowing for smooth navigation through the vascular system. These features are particularly beneficial in minimally invasive procedures, where precision directly impacts patient outcomes.

Customization for Unique Medical Applications

Every medical application has distinct requirements. Customization ensures the liner fits the catheter's specifications perfectly. AccuPath offers tailored solutions, providing a wide range of sizes and configurations to meet diverse needs. Whether the application demands enhanced flexibility, reduced size, or specific surface properties, AccuPath delivers liners that align with the device's unique design. This adaptability ensures optimal performance and patient comfort.

Material Quality and Compliance

Adherence to Medical Standards and Regulations

Material quality and purity are non-negotiable in medical device manufacturing. AccuPath uses high-purity PTFE materials to ensure consistent performance. Its liners comply with stringent FDA and ISO standards, covering biocompatibility and chemical resistance. This adherence to regulations guarantees safety and reliability, minimizing approval delays and additional costs. By meeting these standards, AccuPath supports manufacturers in delivering patient-centric solutions.

Ensuring High-Quality Manufacturing Processes

AccuPath employs advanced etching techniques to enhance adhesion quality, a critical factor in catheter manufacturing. These processes ensure the liners meet the highest standards of chemical resistance and biocompatibility. The company’s commitment to quality extends to every stage of production, resulting in liners that consistently perform in demanding medical environments. This focus on excellence positions AccuPath as a trusted partner in the medical industry.

How AccuPath Simplifies the Selection of Medical-Grade PTFE Tubing

Unique Features of AccuPath Etched PTFE Liners

Advanced Etching Technology for Superior Adhesion

AccuPath employs advanced etching technology to enhance the performance of its PTFE etched liners. This process increases surface roughness and introduces functional groups, boosting surface energy and wettability. These improvements allow adhesives to form stronger bonds, ensuring reliable connections in medical devices. In catheter manufacturing, this technology prevents delamination, maintaining device integrity during critical procedures. The etched PTFE surface also supports smooth insertion, reducing friction and improving patient outcomes.

Consistent Quality and Reliability

AccuPath prioritizes quality and reliability in every PTFE etched liner it produces. The liners exhibit exceptional chemical resistance, protecting against degradation in challenging environments. Their durability ensures they withstand high temperatures and pressures, making them suitable for demanding medical applications. Additionally, the low-friction surface enhances device efficiency, while the biocompatibility guarantees patient safety. These features make AccuPath a trusted partner for medical-grade PTFE tubing.

Customization Options for Diverse Medical Needs

Tailored Solutions for Specific Catheter Applications

AccuPath understands the growing demand for personalized medical solutions. Its PTFE etched liners can be customized to meet specific catheter requirements. Adjustable liner thickness, tailored etching depth, and surface modifications enhance biocompatibility and precision. These tailored solutions ensure the liners integrate seamlessly into various catheter designs, supporting minimally invasive procedures and improving patient comfort.

Wide Range of Sizes and Specifications

AccuPath offers a broad selection of sizes and specifications to accommodate diverse medical applications. The liners are available in ultra-thin and lightweight designs, ideal for minimally invasive devices. Their dimensions, including diameter and wall thickness, can be adjusted to meet precise requirements. This versatility ensures the liners align with the unique needs of each medical device, enhancing functionality and safety.

Customization Aspect | Description |

|---|---|

Liner Thickness | Adjustable to meet specific application requirements. |

Etching Depth | Can be tailored for different performance needs. |

Surface Modifications | Options available to enhance biocompatibility and precision. |

Compliance with Medical Industry Standards

FDA and ISO Certifications for Safety and Quality

AccuPath’s commitment to safety and quality is evident in its adherence to stringent industry standards. The company holds FDA and ISO certifications, including ISO 9001:2015, which ensures consistent manufacturing processes. These certifications guarantee that AccuPath’s medical-grade PTFE tubing meets the highest safety and quality benchmarks, providing peace of mind to manufacturers and healthcare providers.

Commitment to Supporting Patient-Centric Solutions

AccuPath designs its PTFE etched liners with patient-centric solutions in mind. The liners’ flexibility allows medical devices to adapt to the body’s natural contours, reducing discomfort during use. Their low-friction surface facilitates smooth navigation through the vasculature, minimizing resistance and tissue damage. By enhancing device performance, AccuPath supports minimally invasive procedures and improves patient outcomes.

Selecting the right etched PTFE liner is crucial for enhancing catheter performance, ensuring safety, and improving durability. These liners provide a smooth, low-friction surface that enhances patient comfort and reduces complications. Their biocompatibility minimizes risks, while their durability ensures reliable performance in demanding medical environments. The etching process further supports innovative catheter designs by improving adhesion and structural integrity.

AccuPath etched PTFE liners stand out for their exceptional quality, customization options, and compliance with industry standards. Their advanced etching technology preserves PTFE’s core properties while enhancing adhesion. Customization features, such as adjustable liner thickness and surface modifications, allow manufacturers to meet specialized medical needs. AccuPath’s commitment to quality and compliance ensures its liners consistently meet the highest benchmarks in modern healthcare.

Explore AccuPath’s solutions to discover how their medical-grade etched PTFE liners can support your catheter manufacturing needs. Their proven track record in delivering reliable, patient-centric solutions makes them a trusted partner in advancing medical technology.

FAQ

What makes AccuPath etched PTFE liners ideal for medical applications?

AccuPath etched PTFE liners offer superior adhesion, biocompatibility, and durability. These features ensure safety and reliability in medical environments. Their low-friction surface enhances catheter performance, making them a trusted choice for catheter manufacturing.

How does AccuPath ensure precision in catheter manufacturing?

AccuPath uses advanced manufacturing techniques to produce liners with ultra-thin walls and precise dimensions. This precision improves catheter flexibility and functionality, ensuring optimal performance in medical procedures.

Are AccuPath etched PTFE liners compliant with medical standards?

Yes, AccuPath liners meet stringent FDA and ISO certifications. These standards guarantee safety, quality, and reliability, making them suitable for critical medical applications.

Can AccuPath liners be customized for specific catheter designs?

AccuPath offers tailored solutions to meet unique medical needs. Customization options include adjustable liner thickness, etching depth, and surface modifications, ensuring compatibility with diverse catheter designs.

Why is adhesion important in catheter manufacturing?

Adhesion prevents delamination, ensuring the structural integrity of catheters during use. AccuPath’s advanced etching technology enhances adhesion, supporting reliable performance in medical devices.

See Also

Exploring The Role Of PTFE Etched Liners In Catheters

Why PTFE Etched Liners Are Crucial For Catheter Strength

Latest Innovations In Etched PTFE For Catheter Production