Emerging Trends in Medical PTFE Liners

Polytetrafluoroethylene (PTFE) liners have transformed the medical device industry by enhancing performance, reliability, and patient comfort. Their unique properties, such as low friction and chemical resistance, make them indispensable in critical applications like catheters and delivery systems. Etched PTFE for catheter manufacturing, in particular, has gained prominence for its ability to improve adhesion during the production process, ensuring device durability and functionality. By addressing challenges like tissue irritation and insertion difficulties, PTFE liners continue to play a pivotal role in advancing healthcare technologies and expanding treatment possibilities.

Key Takeaways

PTFE liners are essential in medical devices due to their low friction, chemical resistance, and biocompatibility, enhancing patient comfort and device reliability.

Etched PTFE liners improve adhesion and flexibility in catheter manufacturing, allowing for better performance and reduced tissue irritation during procedures.

The trend towards ultra-thin and lightweight PTFE liners supports the demand for minimally invasive medical devices, improving maneuverability and precision.

Integrating antimicrobial coatings into PTFE liners significantly reduces infection risks, making them a safer choice for long-term medical applications.

Nano-material integration in PTFE technology enhances lubricity and enables the development of smart medical devices, paving the way for personalized medicine.

Customization of PTFE liners allows manufacturers to tailor products to specific medical needs, improving the effectiveness and safety of treatments.

Overview of PTFE Liners

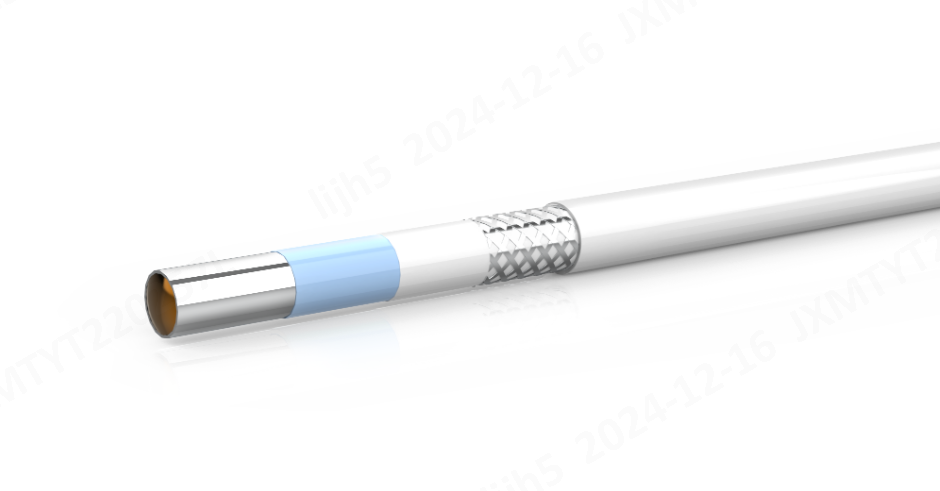

Polytetrafluoroethylene (PTFE) liners have become a cornerstone in the medical device industry due to their exceptional properties and versatility. These liners, crafted from a high-performance fluoropolymer, provide a smooth, inert interface that enhances the functionality and safety of medical devices. Their ability to resist chemical reactions and maintain structural integrity under extreme conditions makes them indispensable in applications such as catheters, tubing, and minimally invasive surgical tools.

Key Properties of PTFE Liners

PTFE liners exhibit several key properties that make them ideal for medical applications:

Low Friction Coefficient: PTFE's ultra-smooth surface minimizes friction, allowing medical devices like catheters to glide effortlessly through the body. This property reduces tissue irritation and enhances patient comfort during procedures.

Chemical Resistance: PTFE remains stable when exposed to a wide range of chemicals, ensuring compatibility with various medical substances and environments.

Durability and Tensile Strength: PTFE liners withstand the mechanical stresses of medical device use without tearing or breaking. This durability ensures long-term reliability in critical applications.

Biocompatibility: PTFE is non-reactive and safe for use in the human body, making it suitable for sensitive medical conditions.

Thermal Stability: PTFE maintains its properties across a broad temperature range, ensuring consistent performance even in demanding medical environments.

These attributes collectively enable PTFE liners to meet the rigorous demands of modern healthcare technologies.

Advantages of Etched PTFE Liners

Etched PTFE liners offer additional benefits that address specific challenges in medical device manufacturing. The etching process modifies the surface of PTFE, enhancing its adhesion properties. This improvement is particularly valuable in catheter manufacturing, where strong bonds between the liner and other components are essential.

Key advantages of etched PTFE liners include:

Improved Adhesion: The etched surface allows better bonding with thermoplastic materials, ensuring the structural integrity of devices like catheters. Manufacturers often incorporate a "strike layer," a thin thermoplastic outer layer, to further enhance adhesion.

Enhanced Flexibility: Etched PTFE liners can be produced with ultra-thin walls, ranging from 0.0004" to 0.002". This design minimizes stiffness in catheter shafts, improving flexibility and maneuverability.

Customization Options: Manufacturers can tailor etched PTFE liners to meet specific medical requirements. Customization includes precise dimensions, cut lengths, and continuous-spooled lengths, enabling personalized solutions for diverse medical applications.

Surface Properties for Lubricity: The etched surface improves lubricity, which is critical for guide catheters and other devices requiring smooth navigation through complex anatomical pathways.

"Etched PTFE for Catheter Manufacturing" has emerged as a game-changer in the medical field. Its ability to enhance adhesion, flexibility, and performance aligns with the growing demand for high-quality, reliable medical devices.

By leveraging these advantages, etched PTFE liners contribute to the development of advanced medical technologies that prioritize patient safety and comfort.

Current Trends in PTFE Liners

Ultra-Thin and Lightweight Designs

The demand for ultra-thin and lightweight PTFE liners has surged in recent years. These advanced designs prioritize flexibility and precision, addressing the growing need for minimally invasive medical devices. Ultra-thin liners, with wall thicknesses as low as 0.0004 inches, reduce stiffness in catheter shafts. This improvement enhances maneuverability, making them ideal for navigating complex anatomical pathways.

Manufacturers have embraced these designs to meet the requirements of modern healthcare. Unlike traditional PTFE liners, which focus on durability and chemical resistance, ultra-thin liners offer a balance between structural integrity and reduced bulk. This innovation supports the trend toward miniaturization in medical devices, enabling the creation of smaller, more efficient systems. By incorporating ultra-thin PTFE liners, medical devices achieve higher performance without compromising patient comfort.

Antimicrobial Coatings and Additives

The integration of antimicrobial coatings into PTFE liners represents a significant advancement in infection control. These coatings inhibit microbial growth on the surface of medical devices, reducing the risk of infections during procedures. This feature is particularly valuable in applications such as catheters, where prolonged contact with bodily fluids increases the likelihood of contamination.

Antimicrobial additives also enhance adhesion properties, ensuring that the liners bond effectively with other device components. This dual functionality makes them a preferred choice for manufacturers aiming to improve both safety and performance. The combination of etched PTFE for catheter manufacturing and antimicrobial coatings exemplifies how innovation addresses critical challenges in healthcare. These coatings not only protect patients but also extend the lifespan of medical devices, reducing the need for frequent replacements.

Etched PTFE for Catheter Manufacturing

Enhancing Flexibility and Performance

Etched PTFE liners have revolutionized catheter manufacturing by significantly improving flexibility and performance. The etching process alters the surface of PTFE, enabling better adhesion with other materials used in catheter assembly. This enhanced adhesion ensures that the liner integrates seamlessly with the catheter's outer layers, creating a robust and durable structure.

Flexibility plays a critical role in catheter functionality. Etched PTFE liners, with their ultra-thin walls, reduce stiffness in catheter shafts. This design allows for smoother navigation through intricate anatomical pathways, minimizing the risk of tissue irritation during procedures. The low friction coefficient of PTFE further enhances this capability, ensuring effortless movement and precise control. These features collectively improve procedural safety and patient outcomes, making etched PTFE an indispensable component in modern catheter systems.

"The ability of etched PTFE to enhance flexibility and performance has made it a cornerstone in the development of advanced catheter technologies."

Improving Surface Properties for Lubricity

Lubricity is a vital characteristic for catheters, as it directly impacts their ease of use and patient comfort. Etched PTFE liners excel in this area by providing a low-friction surface that facilitates smooth insertion and movement within the body. This property reduces resistance, allowing medical professionals to navigate complex vascular systems with greater precision.

The etching process also improves the wettability of PTFE, which enhances its biocompatibility and adhesion properties. By controlling surface roughness, manufacturers can optimize the liner's interaction with bodily fluids, further improving its lubricity. These advancements not only enhance the functionality of guide catheters but also contribute to safer and more efficient medical procedures.

The integration of etched PTFE liners into catheter manufacturing addresses critical challenges in healthcare, such as reducing tissue trauma and improving procedural accuracy. This innovation underscores the importance of surface properties in achieving superior medical device performance.

Customization for Personalized Medical Solutions

The demand for personalized medical solutions has driven the need for customizable components in catheter manufacturing. Etched PTFE liners offer unparalleled versatility, allowing manufacturers to tailor their dimensions, thickness, and surface properties to meet specific medical requirements. This customization ensures that catheters are optimized for individual patient needs, enhancing their effectiveness and safety.

Manufacturers can produce etched PTFE liners in continuous-spooled lengths or precise cut sizes, depending on the application. This flexibility supports the creation of specialized devices for various medical fields, including cardiology, neurology, and minimally invasive surgery. The ability to customize liners also enables the development of innovative delivery systems that align with the growing trend of personalized medicine.

"Etched PTFE for Catheter Manufacturing exemplifies how innovation can address the unique challenges of modern healthcare, paving the way for more effective and patient-centric solutions."

By offering enhanced flexibility, improved surface properties, and extensive customization options, etched PTFE liners continue to set new benchmarks in catheter manufacturing. These advancements highlight their pivotal role in advancing medical technologies and improving patient care.

Applications in Medical Devices

Catheters and Tubing

PTFE liners have become indispensable in the production of catheters and tubing, offering unmatched performance and reliability. Their low-friction surface ensures smooth navigation through complex anatomical pathways, reducing tissue irritation and enhancing patient comfort. This feature is particularly critical in vascular applications, where precision and ease of movement are paramount.

The chemical resistance of PTFE liners allows them to maintain integrity when exposed to various medical substances, ensuring compatibility with a wide range of treatments. Manufacturers often incorporate etched PTFE for catheter manufacturing to improve adhesion between the liner and other catheter components. This innovation enhances the structural durability of catheters, making them more resilient during prolonged use. Additionally, the ultra-thin design of PTFE liners minimizes stiffness in catheter shafts, improving flexibility and maneuverability in intricate procedures.

Minimally Invasive Surgical Tools

Minimally invasive surgical tools rely heavily on PTFE liners to achieve optimal performance. These liners provide a smooth, inert interface that reduces friction, enabling precise control during delicate procedures. Surgeons benefit from the enhanced lubricity of PTFE liners, which facilitates the seamless movement of instruments within confined spaces.

The durability and tensile strength of PTFE liners ensure that surgical tools can withstand the mechanical stresses of repeated use without compromising performance. Their biocompatibility further supports their application in sensitive medical environments, minimizing the risk of adverse reactions. By integrating PTFE liners into minimally invasive tools, manufacturers address the growing demand for safer and more efficient surgical solutions.

Other Medical Tools and Implants

Beyond catheters and surgical tools, PTFE liners play a vital role in various other medical devices and implants. Their versatility makes them suitable for applications such as vascular stents, guide wires, and delivery systems. The low interaction of PTFE liners with medical substances enhances the safety and functionality of these devices, ensuring consistent performance in critical applications.

In implantable devices, PTFE liners provide a stable and non-reactive surface that supports long-term use within the human body. Their thermal stability ensures reliable performance across a wide temperature range, making them ideal for diverse medical conditions. The ability to customize PTFE liners to specific dimensions and properties further expands their applicability, aligning with the trend toward personalized medical solutions.

"PTFE liners have revolutionized the design and functionality of medical devices, offering unparalleled performance and adaptability across a wide range of applications."

By incorporating PTFE liners into medical tools and implants, manufacturers continue to push the boundaries of innovation, delivering advanced solutions that prioritize patient safety and comfort.

Challenges and Solutions

Design Complexities

The intricate nature of medical devices often demands precise engineering, especially when incorporating PTFE liners. Manufacturers face challenges in achieving the perfect balance between flexibility, durability, and functionality. For instance, ultra-thin PTFE liners must maintain structural integrity while providing the flexibility required for minimally invasive procedures. This complexity increases the risk of design flaws, which can compromise device performance.

To address these challenges, manufacturers rely on advanced technologies and meticulous testing protocols. Computer-aided design (CAD) tools enable engineers to simulate various scenarios, ensuring that PTFE liners meet stringent performance standards. Additionally, the etching process enhances the adhesion properties of PTFE, allowing seamless integration with other materials. This innovation minimizes design failures and ensures that medical devices perform reliably under demanding conditions.

"Etching prepares the PTFE surface, enabling a stronger and more durable bond between the PTFE and the additional materials."

By leveraging these solutions, manufacturers overcome design complexities and deliver high-quality medical devices that prioritize patient safety.

Regulatory and Compliance Requirements

The medical device industry operates under strict regulatory frameworks to ensure patient safety and product efficacy. PTFE liners, as critical components, must comply with rigorous standards set by organizations like the FDA and ISO. These regulations cover biocompatibility, chemical resistance, and performance under various conditions. Non-compliance can lead to delays in product approval, increased costs, and potential legal repercussions.

Manufacturers address these challenges by implementing robust quality management systems. Regular audits, thorough documentation, and adherence to international standards ensure compliance throughout the production process. Collaboration with regulatory experts also helps navigate complex requirements, reducing the risk of non-compliance.

"PTFE liners are essential in enhancing the performance and safety of medical devices by providing a smooth, inert interface that minimizes interaction with medical substances."

This proactive approach not only ensures regulatory compliance but also builds trust among healthcare providers and patients.

Cost Pressures in Manufacturing

The production of PTFE liners involves advanced materials and processes, which can drive up manufacturing costs. Ultra-thin designs, antimicrobial coatings, and nano-material integration further increase expenses. Additionally, the demand for customized solutions adds to the financial burden, as it requires specialized equipment and expertise.

To mitigate these cost pressures, manufacturers adopt innovative strategies. Automation streamlines production, reducing labor costs and minimizing errors. Bulk procurement of raw materials lowers expenses, while partnerships with suppliers ensure a steady supply chain. Technological advancements also play a pivotal role in optimizing production efficiency.

"Technological advancements play a crucial role in propelling the Etched PTFE Liner market forward."

By embracing these solutions, manufacturers balance cost-efficiency with the need for high-quality PTFE liners. This approach ensures that advanced medical devices remain accessible to healthcare providers and patients worldwide.

Sustainability in PTFE Manufacturing

Sustainability has become a critical focus in PTFE manufacturing. The production process traditionally involves energy-intensive methods and generates waste, raising concerns about environmental impact. To address these challenges, manufacturers are adopting eco-friendly practices and exploring alternative production techniques.

One approach involves recycling PTFE materials to reduce waste. By reprocessing used liners, manufacturers can minimize raw material consumption and lower production costs. Another strategy focuses on developing bio-based alternatives to traditional PTFE. These materials offer similar properties while reducing reliance on non-renewable resources.

"Sustainability in PTFE manufacturing is not just a trend; it is a necessity for ensuring the long-term viability of medical technologies."

By prioritizing sustainability, the PTFE industry contributes to a greener future while maintaining high standards of quality and performance.

PTFE liners have revolutionized medical technology by enhancing the functionality, reliability, and comfort of medical devices. Their smooth, inert interface minimizes interaction with medical substances, making them indispensable in sensitive applications. Key trends, such as etched PTFE for catheter manufacturing, have improved device performance by increasing flexibility and adhesion. The future of PTFE liners lies in personalized solutions and advanced technologies, including smart materials and sustainable manufacturing. Continued innovation and collaboration within the medical device industry will drive these advancements, ensuring that PTFE liners remain at the forefront of healthcare innovation.

See Also

Exploring The Importance Of PTFE Etched Liners