Electropolished Nitinol Tubes in Endoscopy: Benefits for 2025

You can expect the electropolished nitinol tube for endoscopic devices in 2025 to have smoother surfaces. It will also have lower risks and last longer. These features can help you at work in many ways:

Aspect | Details |

|---|---|

Surface Quality | Ra <0.2 μm, less friction, less harm to blood vessels |

Safety | Better biocompatibility, fewer problems, less chance of device failure |

Performance Longevity | Very good accuracy, lasts longer, fewer replacements needed |

Key Takeaways

Electropolished nitinol tubes have very smooth surfaces. This lowers friction and helps stop tissue damage during procedures. - These tubes do not rust easily, so they stay strong and safe for a long time. - Electropolished tubes are made with great care. This makes them work the same way every time, so doctors can trust them for medical use.

Benefits of Electropolishing

Surface Smoothness

Electropolishing takes away rough spots from nitinol tubes. The tubes feel smooth and look shiny after this process. A smooth tube slides easily inside the body. This lowers the chance of hurting blood vessels or tissues.

Measurable Outcome | Value |

|---|---|

Surface roughness improvement (Ra) | 75% better than untreated Ra |

Best Ra value | Below 0.5 μm |

Fatigue life improvement | About 20% at low stresses |

Electropolishing makes nitinol tubes much less rough. The roughness drops from 10.86 μm to 1.44 μm. This helps the tubes last longer and move better through tissues. A smoother tube also helps cells stick, which is good for medical devices.

Electropolishing takes off burrs and fixes surface flaws.

It removes spots that could rust or hold dirt.

When you look at other ways to finish tubes, electropolishing stands out:

Mechanical polishing leaves small lines that can weaken tubes.

Chemical etching can make tubes thin and dull.

Electropolishing gives better smoothness, stops rust, and is safer for the body.

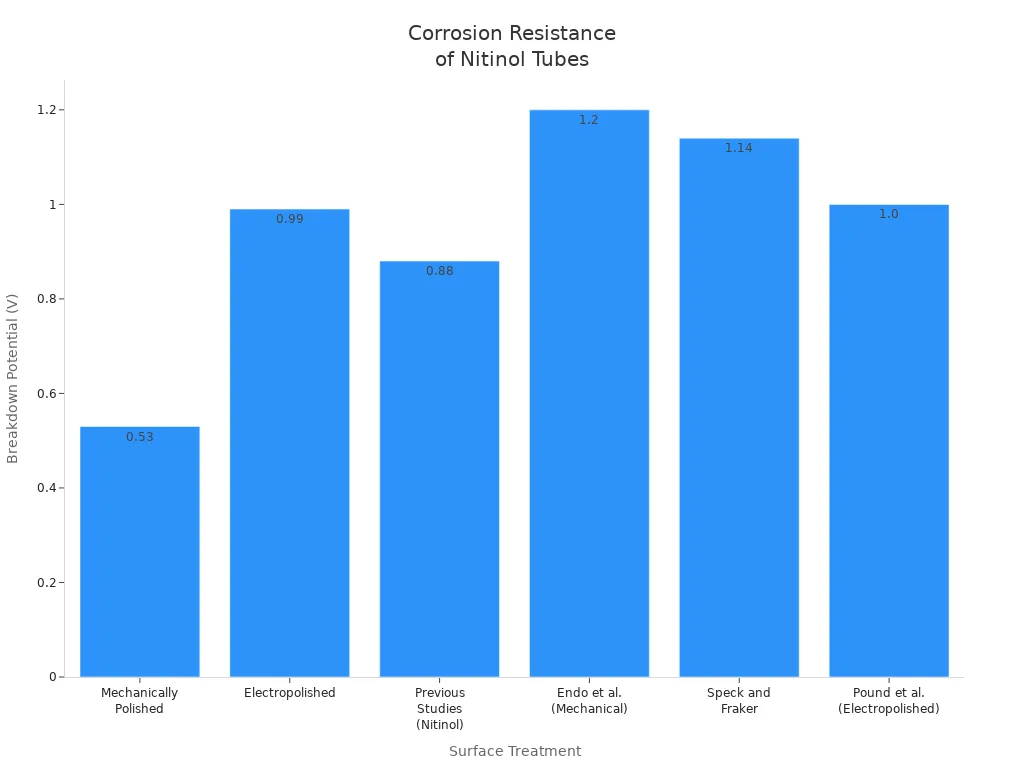

Corrosion Resistance

Corrosion resistance is a key benefit of electropolishing nitinol tubes. You need this to keep medical devices safe for a long time. Electropolishing adds a thin titanium oxide layer to the tube. This layer stops nickel from leaking and keeps the tube from rusting.

Surface Treatment | Breakdown Potential (V) | Corrosion Resistance Improvement |

|---|---|---|

Mechanically Polished | 0.53 | Lower |

Electropolished | 0.99 | Higher |

Previous Studies (Nitinol) | 0.88 | Moderate |

Pound et al. (Electropolished) | 1.0 | Significantly Higher |

Electropolished nitinol tubes fight rust at higher voltages than polished ones. This means your devices last longer and stay safe for patients. The protective layer keeps metal ions out of the body, which is very important for health.

Tip: Devices that resist rust need fewer replacements. This saves time and lowers risks for you and your patients.

Pathogen & Contaminant Reduction

You want endoscopic devices to be clean and safe. Electropolishing makes the surface so smooth that germs have fewer places to stick. This helps stop infections.

Study/Property | Findings/Implications |

|---|---|

Electropolishing & NiTi alloys | Decreases surface nickel, increases breakdown potential |

Electropolished nitinol in saline | Increased breakdown resistance, less localized corrosion |

Biocompatibility | Enhanced, minimizing pathogen adhesion |

A smooth surface is easier to clean. You can sterilize the device better, which lowers infection risk. Electropolishing removes up to 53% of copper and 47% of nickel from the tube. This takes time but makes the product safer.

Electropolishing also smooths out tiny bumps. This makes it harder for bacteria to stick and grow. It lowers the chance of infection during procedures.

Precision & Dimensional Control

Precision is important for nitinol tubes in surgery. Electropolishing helps control the tube's size and surface. This gives you the same results every time.

Measurement Technique | Purpose |

|---|---|

Profilometry | Measures average roughness (Ra) across the tubing. |

Atomic Force Microscopy | Detects tiny changes in surface roughness. |

Scanning Electron Microscopy | Identifies inclusions or defects on the surface. |

Regular Calibration | Maintains accuracy in measurements. |

Equipment Maintenance | Ensures consistency in tubing thickness and finish. |

Benefit | Impact on Performance |

|---|---|

Smoother Surface | Reduces risk of fatigue cracking. |

Improved Corrosion Resistance | Essential for implants and patient safety. |

Enhanced Coating Adhesion | Ensures better bonding for coatings. |

Burr-Free Lumen | Allows smooth guidewire passage, reducing friction. |

Improved Flexibility | Enables controlled bending without cracking. |

Enhanced Fatigue Resistance | Resists microcrack propagation in dynamic systems. |

Better Device Control | Improves pushability and torque transmission. |

Consistent Quality | Enables tight tolerances and reliable performance. |

Nitinol tubes are light and strong. They bend easily and do not kink. This helps you move through the body with less harm. Patients recover faster and have fewer problems. Electropolishing makes sure every tube is the right size and shape. This is very important for successful surgeries.

Electropolished Nitinol Tube for Endoscopic Devices

Device Performance & Safety

You count on the electropolished nitinol tube to work well every time. Electropolishing makes the tube’s surface very smooth. This smoothness lowers friction and helps the device move easily. It also helps stop tissue from getting hurt. The process makes the tube resist rust, so it stays strong and safe for longer. You see fewer allergies and less infection risk because the tube is safe for the body and fights germs. The table below shows how these features make the device safer:

Benefit | Contribution to Safety Outcomes |

|---|---|

Smooth surfaces | Less friction means less tissue damage during use. |

Corrosion resistance | Lowers the chance of the tube breaking over time. |

Fatigue resistance | Makes sure the tube does not break after many uses. |

Biocompatibility | Fewer allergies and infections for patients. |

Compliance with regulatory standards | Makes sure the tube is safe for medical use. |

Reliability in Medical Devices

You want your medical tools to work every time you use them. The electropolished nitinol tube is known for being reliable. Nitinol is strong and can bend many times without breaking. Electropolishing makes nitinol even more dependable than oxidized tubes.

Surface Finish | Breakdown Potential (mV) |

|---|---|

Oxidized Tubing | -117 |

Electropolished (EP) | Up to 1000 |

Nitinol tubes last longer in medical devices.

They can be used many times because they resist breaking.

Electropolishing keeps the quality the same for each tube.

Compliance & Future Trends

Medical devices must follow strict rules to keep people safe. Electropolished nitinol tubes help meet these rules. Electropolishing takes away dirt and flaws, making the tube safe for the body. This also helps stop germs and lowers infection risk. In 2025, more medical devices will use electropolishing. Tests like DSC show that nitinol lasts longer and resists rust better after electropolishing. You can expect these tubes to lead in safety and performance for new medical devices.

You get a lot of good things from electropolished nitinol tubes in endoscopic devices.

The surfaces are very smooth. They do not have defects. This helps stop bacteria from sticking.

The tubes resist corrosion well. You can clean them easily.

The parts are precise and safe. They work well with the body.

Medical technology is always getting better.

You will use these new materials for safer care. You can count on them to be reliable.

FAQ

What makes electropolished nitinol tubes better for endoscopy?

These tubes have smoother surfaces. They also resist rust better. They are easier to keep clean. These things help make devices safer. They also help them work better during endoscopy.

Tip: Smoother tubes hurt tissue less and lower infection risk.

Can you reuse electropolished nitinol tubes safely?

You can use these tubes more than once. They do not rust or wear out fast. Always clean and sterilize them the right way. Follow your hospital’s rules for cleaning.

How do you clean electropolished nitinol tubes?

You clean these tubes with normal medical sterilization. The smooth surface makes it easier to wash away germs and dirt. It is easier than cleaning tubes that are not electropolished.

See Also

Nitinol Tubing: The Next Generation of Medical Innovations

The Importance of Nitinol Tubing in Minimally Invasive Surgery

Nitinol Tubing's Impact on the Future of Medical Technology

Nitinol Tubing Applications Transforming Healthcare Device Solutions