Surprising ways 0.05mm wall thickness Nitinol capillary tubing changes medical tools

You can revolutionize medical and industrial tools by customizing 0.05mm wall thickness Nitinol capillary tubing. Nitinol stands out for its ability to recover from up to 13% deformation strain, instantly returning to its original shape without permanent damage. This superelasticity, confirmed through X-ray diffraction and cyclic-dynamic testing, supports the development of flexible, resilient devices like self-expanding stents. When you use advanced customization techniques, you gain measurable improvements in tool performance, as real-time analytics and predictive dashboards highlight faster decision-making and greater efficiency.

Key Takeaways

Customizing 0.05mm wall thickness Nitinol tubing with precise cutting and shape-setting improves medical device fit, flexibility, and durability.

Maintaining clean, smooth surfaces ensures biocompatibility and safety, reducing risks like inflammation and allergic reactions.

Ultra-thin Nitinol tubing offers superior flexibility and strength, enabling smaller, less invasive medical tools that perform reliably.

Advanced surface treatments and quality control extend device lifespan and meet strict medical safety standards.

Beyond healthcare, Nitinol tubing enhances industrial sensors by reducing vibration and supporting precise, durable components.

Customizing 0.05mm wall thickness Nitinol capillary tubing

Precision Cutting and Sizing

When you customize 0.05mm wall thickness Nitinol capillary tubing, you must pay close attention to every detail in your customer’s drawings and samples. Even the smallest deviation in size can change how a medical device works. For example, if you make a stent or heart valve with tubing that is even a few microns off, it might not fit or function as intended. You need to achieve positional accuracy around ±2.5 microns and cutting tolerances near ±10 microns. These tolerances are much tighter than what you find in traditional tubing.

You use advanced manufacturing techniques like laser cutting and ultrasonic gauging to reach these exact dimensions. These methods help you maintain a consistent wall thickness and diameter throughout the tubing. When you follow these steps, you ensure that the tubing matches the exact sizes, thicknesses, and finishes your customer needs. This level of precision also supports the tubing’s flexibility, strength, and shape memory, which are essential for medical tools.

Statistical comparisons between different manufacturing methods show that precision cutting and sizing can double or even triple the fatigue life of Nitinol tubing. When you minimize defects and control the microstructure, you reduce the risk of fatigue failure. This means your medical devices last longer and perform better.

Tip: Always work closely with your customers and use advanced quality checks, such as those required by ISO 13485 and ASTM F2516, to guarantee the best results.

Shape-Setting Methods

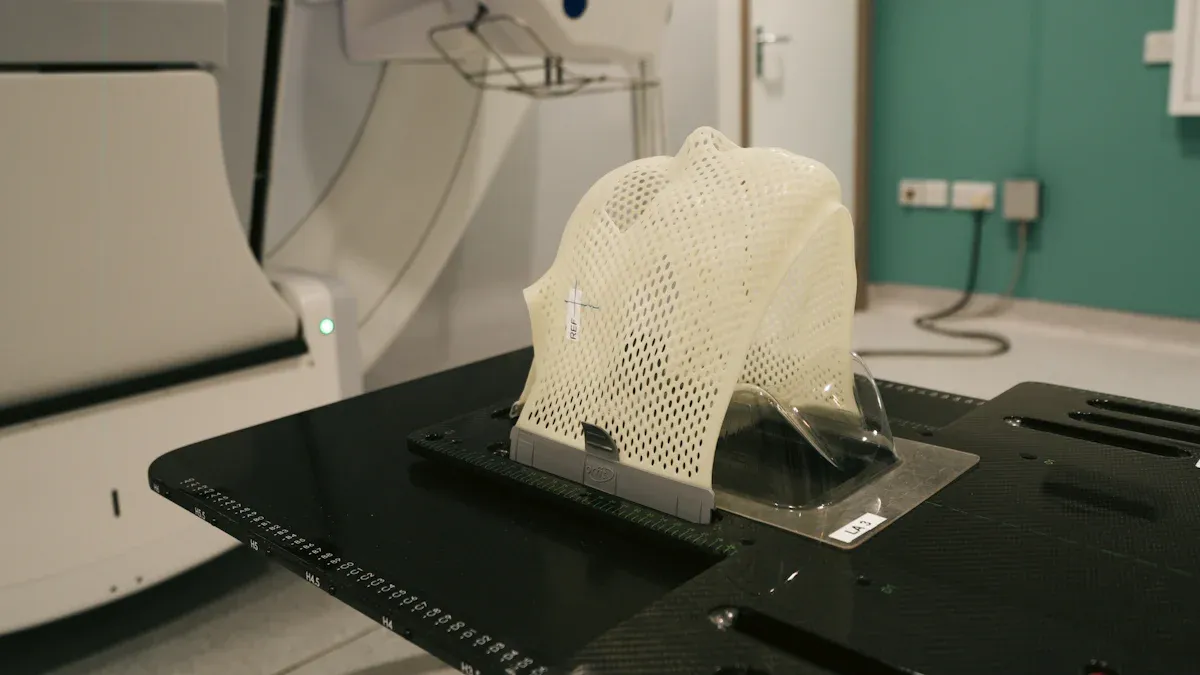

Shape-setting is a key step when you customize 0.05mm wall thickness Nitinol capillary tubing. You use shape-setting to give the tubing its final geometry, which is critical for devices like stents and orthodontic wires. You can use thermal or mechanical processes to set the shape. For example, you might heat the tubing to a specific temperature and then cool it in a mold. This process locks in the desired shape and ensures the tubing will return to that shape when needed.

Research shows that shape-memory materials like Nitinol have been used in orthodontic wires since the 1970s. These wires provide constant, gentle forces that improve comfort and performance for patients. Patents and studies confirm that shape-setting methods help you create wires and tubes with precise geometry and reliable function. Experimental data and computer models also show that the way you shape-set the tubing affects its mechanical properties and how well it works in the body. By controlling the shape-setting process, you can optimize the tubing for each specific medical application.

Surface Quality and Cleanliness

Surface quality and cleanliness are just as important as size and shape when you work with 0.05mm wall thickness Nitinol capillary tubing. Medical devices must have a bright, smooth, and oil-free surface to ensure biocompatibility and allow for proper sterilization. If the surface is rough or contaminated, it can cause problems in the body, such as inflammation or infection.

You can measure surface quality and cleanliness using several quantitative tests:

In vitro tests for skin sensitization, such as measuring IL-18 release and CD86 expression on immune cells.

Standardized tests for emissions, including particulate matter, volatile organic compounds (VOCs), and leachables.

Microbiological cleanliness (bioburden) testing to check for surface contamination.

Surface morphology characterization, including roughness, chemistry, and porosity.

You also assess how the surface affects cell attachment, protein adsorption, and overall biocompatibility. These tests help you confirm that your tubing meets strict medical standards and will perform safely in the body.

Note: Always aim for a surface that is not only clean but also optimized for cell compatibility and long-term use in medical environments.

Performance in Medical Tools

Flexibility and Miniaturization

You can achieve remarkable flexibility and miniaturization in medical devices by using 0.05mm wall thickness Nitinol capillary tubing. The unique superelastic properties of Nitinol, combined with ultra-thin walls, allow you to design tools that bend and flex without breaking. Controlled mechanical tests on active needle prototypes show a 32% to 40% increase in flexibility compared to commercial needles with thicker walls. These thin-walled needles perform as well or better in puncture tests, reaching internal organs with minimal deflection. This means you can create smaller, less invasive devices that still deliver high performance. The tight wall thickness tolerances, often within ±0.005mm, ensure that each device functions consistently and reliably. You can trust that your tools will maintain their shape and flexibility, even in the most demanding procedures.

Tip: When you use 0.05mm wall thickness Nitinol capillary tubing, you open the door to new possibilities in minimally invasive surgery and advanced diagnostic tools.

Biocompatibility and Safety

You must prioritize biocompatibility and safety when designing medical tools. The surface quality and alloy composition of Nitinol play a critical role in patient outcomes. Advanced surface treatments, such as passivation, electropolishing, and titanium oxide layer application, reduce corrosion and nickel ion release. These treatments help prevent hypersensitivity reactions, which affect a significant number of patients. Coatings with ceramics or polymers, like PTFE, further enhance corrosion resistance and minimize toxicological risks. Regulatory agencies, including the FDA, require nickel release testing to ensure device safety.

Surface treatments lower the risk of nickel ion release, reducing allergic reactions.

Coatings improve hemocompatibility, making devices safer for use in blood-contact applications.

In-vitro and in-vivo studies confirm that superior surface processing leads to better patient safety and device longevity.

Controlled laboratory tests using animal models show that Nitinol devices, including those made from ultra-thin tubing, do not cause tissue damage or debris accumulation. Statistical analysis of tissue response and device performance confirms the high level of biocompatibility you can achieve with proper manufacturing and surface finishing.

Durability and Corrosion Resistance

You need your medical devices to last. 0.05mm wall thickness Nitinol capillary tubing offers outstanding durability and corrosion resistance. Electropolished Nitinol tubing can reach a breakdown potential of up to 1000 mV, far surpassing oxidized tubing. Salt spray tests simulate real-world conditions, confirming long-term reliability. Shape memory tests show that Nitinol tubing recovers its original form after deformation, which is essential for orthopedic and neurovascular devices.

Compared to traditional materials like stainless steel, Nitinol provides higher tensile strength, greater fatigue resistance, and superior corrosion protection. The following table highlights key performance metrics:

Metric | Nitinol Tubing Result |

|---|---|

Tensile Strength | 500–900 MPa |

Local Strains | Up to 6% |

Cycles to Failure | Up to 10 million cycles |

Strain Amplitudes | 0.5%–2.9% |

Cold Work Percentage | 20%–30% |

Vacuum melting and precise alloy composition control eliminate contaminants and optimize the balance of nickel and titanium. Electropolishing removes surface imperfections, reducing the risk of thrombosis and improving biocompatibility. These advanced processes ensure that your devices meet the highest standards for mechanical integrity and corrosion resistance.

Note: By choosing 0.05mm wall thickness Nitinol capillary tubing, you ensure your medical tools remain safe, reliable, and effective throughout their lifespan.

Industrial Applications

High-Precision Sensors

You can use ultra-thin Nitinol capillary tubing to improve high-precision industrial sensors. Nitinol’s superelasticity and high intrinsic damping make it ideal for environments where vibration control is critical. When you embed Nitinol tubing into sensor assemblies, you help reduce vibration amplitude and maintain structural stiffness. Experimental studies show that Shape Memory Alloys, like Nitinol, can lower vibration by up to 30% in wind tunnel bending tests and by 47% in rotating blade displacement. These properties allow your sensors to deliver stable, accurate readings even in harsh or dynamic conditions. You gain the ability to design smaller, lighter sensors without sacrificing performance. This advantage is especially important in aerospace, automotive, and robotics industries, where every gram and every micron matter.

Tip: Choose Nitinol tubing for your sensor designs when you need both flexibility and vibration suppression in compact spaces.

Traceability and Identification

You must ensure that every component in your industrial system is traceable and identifiable. Laser marking on ultra-thin Nitinol tubing gives you permanent, legible, and durable identifiers. These marks withstand wear, chemicals, and extreme temperatures, supporting regulatory compliance and quality control. The market for laser marking is growing rapidly, as shown in the table below:

Attribute | Key Data/Insight |

|---|---|

Market Size (2024) | USD 1.0 Billion |

Market Forecast (2033) | USD 2.1 Billion |

Growth Rate (2025-33) | 7.8% annual growth |

Key Benefits | Durability, precision, traceability for compliance in healthcare, automotive, aerospace sectors |

Regulatory Drivers | FDA UDIs, automotive traceability, aerospace safety standards |

Laser marking enables real-time data synchronization with inventory systems.

You can quickly identify and correct defects, improving quality control.

Automated data capture, such as barcodes or QR codes, reduces human error.

You support product safety and recall management across the supply chain.

Laser marking technology continues to advance, with fiber lasers and software integration making compliance easier. You benefit from efficient inventory management and enhanced product tracking. By using these methods, you meet strict industry regulations and maintain operational integrity.

Practical Tips and Pitfalls

Supplier Selection

You should always choose suppliers who specialize in refractory metals and shape memory alloys. These manufacturers understand the unique challenges of working with 0.05mm wall thickness Nitinol capillary tubing. They use advanced equipment and strict process controls. When you work with experienced suppliers, you get tubing that meets tight tolerances and high-quality standards. Ask for proof of certifications, such as ISO 13485 for medical devices. Reliable suppliers provide detailed documentation and traceability for every batch. This helps you avoid delays and costly rework.

Tip: Build long-term relationships with suppliers who offer technical support and are willing to collaborate on custom projects.

Quality Control and Testing

You must perform thorough testing and validation before using Nitinol tubing in your devices. Start with biocompatibility testing that follows ISO 10993 standards. This ensures the material is safe, non-toxic, and does not react with human tissue. Mechanical and fatigue testing, such as tensile, compression, and torsion tests, check that the tubing can handle real-world stresses. Chemical and material testing, including extractable and leachable analysis, help you detect harmful compounds. Wear and debris analysis using advanced microscopy techniques can reveal if the tubing generates particles that might cause tissue reactions. Cytotoxicity assays in the lab give early warnings about possible toxicity. By combining these tests, you confirm that your devices are safe, effective, and durable.

Biocompatibility testing ensures safety for human contact.

Mechanical and fatigue tests confirm strength and durability.

Chemical analysis checks for harmful substances.

Wear and debris analysis prevents adverse tissue reactions.

Common Mistakes to Avoid

You can avoid many problems by learning from common mistakes. Some teams skip detailed drawings or fail to communicate exact requirements to suppliers. This often leads to tubing that does not fit or perform as needed. Others overlook the importance of surface quality, which can cause poor biocompatibility or device failure. Rushing the testing phase or ignoring regulatory standards puts patients at risk and can delay product approval.

Common pitfalls include:

Choosing inexperienced suppliers

Ignoring tight tolerances

Skipping surface finishing steps

Inadequate testing and documentation

Note: Always follow a clear process from design to delivery. Double-check every step to ensure your medical tools meet the highest standards.

You unlock new levels of flexibility, safety, and durability when you customize 0.05mm wall thickness Nitinol capillary tubing. Advanced strategies—like optimizing tube geometry and surface quality—let you tailor devices for precise clinical or industrial needs. Statistical analyses show that adjusting wire diameter and stent shape improves both expansion force and anatomical fit. The table below highlights how customization transforms tool performance:

Summary Aspect | Description |

|---|---|

Fatigue Life Cycles | Up to 600 million cycles with enhanced durability |

Superelasticity Range | 4% plateau strain range for superior flexibility |

Cyclic Behavior | Stable, reversible strain around 2.8% |

Collaborate with specialized manufacturers for best results.

Explore simulation and testing to optimize your next project.

Consult experts for advanced customization or regulatory guidance.

FAQ

What makes 0.05mm wall thickness Nitinol tubing special for medical devices?

You get unmatched flexibility and strength with this ultra-thin tubing. The superelastic property lets your device bend and return to shape. This feature supports safer, less invasive procedures.

Tip: Thinner walls mean smaller, more precise tools for doctors.

How do you ensure Nitinol tubing is safe for patients?

You use strict testing and surface treatments. These steps remove harmful particles and reduce nickel release. You meet FDA and ISO standards for biocompatibility.

Biocompatibility testing

Surface finishing

Nickel release checks

Can you customize the shape of Nitinol tubing?

Yes, you can. You use heat or mechanical processes to set the final shape. This lets you create stents, wires, or other tools that fit your exact needs.

Customization Method | Benefit |

|---|---|

Heat setting | Precise geometry |

Mechanical forming | Unique designs |

What industries use ultra-thin Nitinol tubing besides healthcare?

You find this tubing in aerospace, robotics, and automotive sensors. The tubing’s flexibility and durability help you build lighter, more reliable equipment.

Note: Many industries choose Nitinol for its vibration control and long life.

See Also

Nitinol Tubing Transforming The Future Of Medical Devices

The Manufacturing Process Behind Nitinol Tubing For Medicine

The Importance Of Nitinol Tubing In Modern Medical Use