The Science of Customizable Nitinol Stents in Neurovascular Care

Nitinol has revolutionized neurovascular care through its unique properties, making it indispensable in medical advancements. This alloy exhibits shape memory and superelasticity, enabling precise deployment in intricate vascular systems. Customizable nitinol stents address patient-specific needs, enhancing treatment outcomes. For instance, a Customizable Nitinol Stent for Mechanical Thrombectomy can be tailored to navigate complex neurovascular pathways, ensuring effective clot removal. These stents adapt to the body’s dynamics, providing unmatched flexibility and reliability. By integrating cutting-edge materials like nitinol, medical professionals can deliver safer and more effective interventions for life-threatening conditions.

Key Takeaways

Nitinol stents have special features like shape memory and flexibility. These make them great for tricky brain and blood vessel surgeries.

Custom nitinol stents fit each patient’s body better. This helps doctors succeed more during treatments.

Special coatings make nitinol stents safer for the body. They also stop the metal from rusting over time.

Nitinol stents work well for fixing problems like aneurysms and clots. They help patients heal faster and feel better.

New science and technology keep improving nitinol stents. These changes make them work better in medical treatments.

Understanding Nitinol

Unique Properties of Nitinol

Nitinol stands out due to its extraordinary ability to undergo phase transitions between two distinct structures: the austenite phase and the martensite phase. The austenite phase, characterized by a simple cubic B2 structure, provides stability at higher temperatures. In contrast, the martensite phase, with its monoclinic B19’ structure, dominates at lower temperatures. These transitions are temperature-dependent, with specific thresholds marking the start and finish of each phase. This phenomenon creates a hysteresis effect during thermal cycles, enabling nitinol to exhibit shape memory and superelasticity.

Superelasticity allows nitinol to recover its original shape after deformation, even under significant stress. This property is particularly evident in the austenite phase, where the material demonstrates elastic, almost linear behavior at temperatures around 81°C. Conversely, in the martensite phase, nitinol stretches due to detwinning and elastic deformation, as observed at temperatures as low as 18°C. Controlled experiments further reveal its ability to respond differently under similar loading conditions, showcasing its adaptability.

Nitinol's unique properties make it indispensable in applications requiring precision and reliability. AccuPath leverages these characteristics to manufacture high-quality nitinol tubing, ensuring optimal performance in demanding environments.

Why Nitinol is Ideal for Medical Applications

Nitinol's combination of shape memory, superelasticity, and biocompatibility makes it the preferred choice for medical applications. Unlike traditional alloys such as steel or aluminum, nitinol can return to its original shape after deformation, ensuring consistent functionality in dynamic environments. This feature is crucial for devices like stents, which must adapt to the body's movements while maintaining their structural integrity.

Its superelasticity further enhances its suitability for medical applications. For instance, cyclic tension compression stress-strain curves of superelastic nitinol alloys demonstrate their ability to withstand repeated stress without compromising performance. This property is vital for devices exposed to continuous mechanical forces, such as neurovascular stents.

Additionally, nitinol's corrosion resistance ensures long-term durability, reducing the risk of material degradation inside the body. Its biocompatibility minimizes adverse reactions, making it safe for implantable devices. Peer-reviewed studies highlight its superior fatigue-crack growth behavior across various temperatures, reinforcing its reliability in diverse medical scenarios.

Figure | Description |

|---|---|

8 | Fatigue-crack growth behavior comparison across stable and superelastic phases. |

10 | NiTi S-N compression fatigue curve. |

12 | Cyclic tension compression stress-strain curves of superelastic NiTi alloy. |

AccuPath specializes in producing nitinol tubing tailored for medical applications. Their expertise ensures that healthcare professionals receive materials optimized for precision, flexibility, and durability, enabling safer and more effective interventions.

Customizing Nitinol Stents

Alloy Formation and Composition

The customization of nitinol stents begins with precise alloy formation. Nitinol, a blend of nickel and titanium, exhibits unique properties based on its composition. Adjusting the nickel-to-titanium ratio allows manufacturers to tailor the stent's superelasticity and shape memory effects. For instance, a higher nickel content enhances the material's ability to recover its shape after deformation, making it ideal for intricate neurovascular applications.

Aspect | Details |

|---|---|

Heat Treatment Protocol | Solution cycle at 900 °C for 1 hour followed by aging cycle at 450 °C for 30 minutes. |

Phase Transformation | Achieved distinct one-step phase transformation with an Af temperature increase to 30.2 °C. |

Microstructure | Formation of ultrafine metastable Ni-rich precipitate (Ni4Ti3) and R-phase confirmed by TEM. |

Superelasticity | Recovery ratio of over 90% and recoverable strain of more than 6.5% after initial cycles. |

Hardness | Hardness of heat-treated samples less affected by cyclic loading. |

Quality control plays a critical role in ensuring that each stent meets regulatory standards. This guarantees optimal performance in clinical settings, especially for life-saving neurovascular procedures.

Heat Treatment and Shape Memory Programming

Heat treatment is a vital step in programming the shape memory of nitinol stents. This process involves heating the alloy to specific temperatures, followed by controlled cooling. The training of shape memory alloys, such as NiTiCuV, demonstrates significant temperature increases during tensile tests. These temperature changes stabilize the material, ensuring it retains its programmed shape even after repeated use.

Differential scanning calorimetry (DSC) measurements confirm the effectiveness of this process. They reveal changes in the material's caloric properties before and after training, highlighting the relationship between mechanical and thermal stabilization. This ensures that nitinol stents can adapt to the body's dynamic environment while maintaining their structural integrity.

Surface Modifications for Biocompatibility

Surface modifications enhance the biocompatibility of nitinol stents, making them safer for implantation. Techniques such as electropolishing and coating with biocompatible materials reduce the risk of adverse reactions. These modifications also improve the stent's corrosion resistance, ensuring long-term durability inside the body.

Nitinol's natural properties already make it an excellent choice for medical devices. However, surface treatments further optimize its performance, ensuring it meets the stringent requirements of neurovascular care. By combining advanced material science with innovative manufacturing techniques, nitinol stents continue to set new standards in patient safety and treatment efficacy.

Applications of Nitinol Stents in Neurovascular Care

Treating Aneurysms with Nitinol Stents

Nitinol stents have transformed the treatment of cerebral aneurysms, offering a reliable solution for managing these life-threatening conditions. The Neuroform stent, the first self-expanding nitinol stent approved for wide-necked aneurysms, marked a significant milestone in neurovascular care. While early studies highlighted its feasibility and effectiveness, challenges such as deployment difficulty and stent migration prompted the development of advanced designs. Subsequent innovations, including the LEO and Enterprise stents, addressed these limitations, improving both safety and performance.

Flow-diverters, a specialized category of nitinol stents, have further expanded the applications of this technology. These devices reduce blood flow to aneurysms while preserving circulation in adjacent branches. Their mechanical properties, derived from nitinol's ability to undergo extreme deformation, ensure precise deployment even in complex vascular environments. Clinical data underscores their effectiveness, with aneurysmal complete occlusion rates reaching 76%. Procedure-related morbidity and mortality rates remain low, at 5% and 4%, respectively.

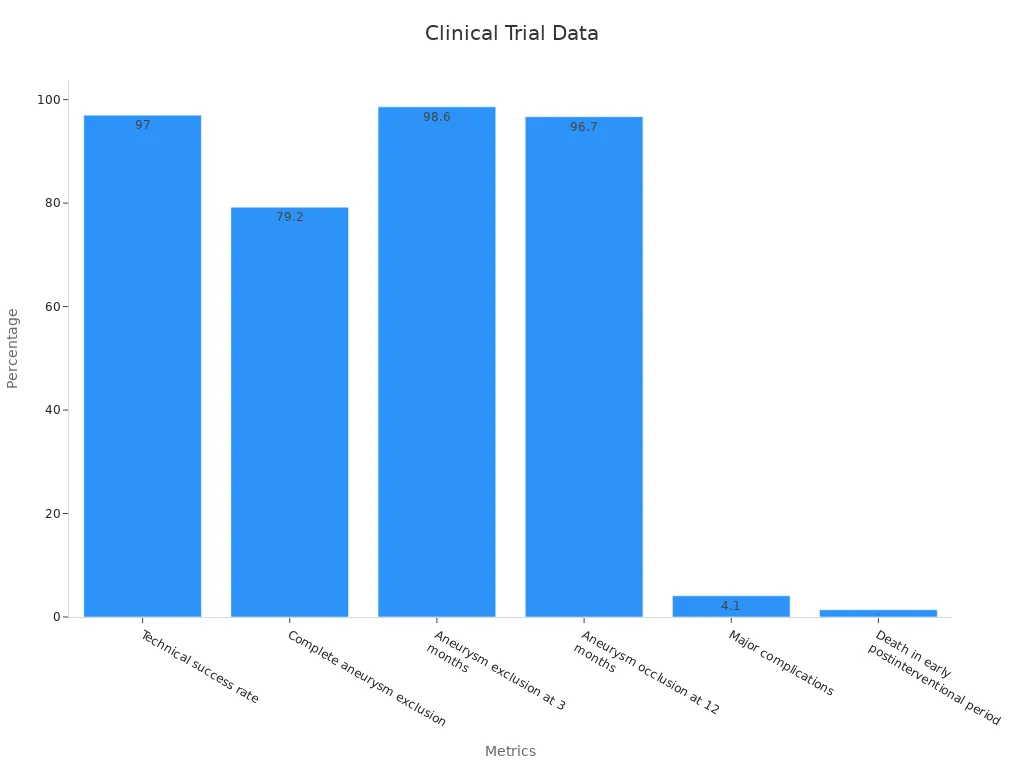

A clinical trial evaluating nitinol stents for aneurysm treatment demonstrated remarkable outcomes. The technical success rate reached 97%, with 79.2% of patients achieving complete aneurysm exclusion. At three months, this figure rose to 98.6%, and at 12 months, 96.7% of patients experienced successful occlusion. Major complications occurred in only 4.1% of cases, highlighting the safety of this approach.

Metric | Result |

|---|---|

Technical success rate | 97% (70 of 72 patients) |

Complete aneurysm exclusion | 79.2% (57 of 72 patients) |

Aneurysm exclusion at 3 months | 98.6% (70 of 71 patients) |

Aneurysm occlusion at 12 months | 96.7% (29 of 30 patients) |

Major complications | 4.1% (3 patients) |

Death in early postinterventional period | 1.4% (1 patient) |

These results demonstrate the critical role of nitinol stents in improving patient outcomes for aneurysm treatment.

Customizable Nitinol Stent for Mechanical Thrombectomy

Mechanical thrombectomy, a procedure to remove blood clots from blocked arteries, has benefited significantly from customizable nitinol stents. These stents are designed to navigate the intricate pathways of the neurovascular system, ensuring effective clot retrieval. The customizable nitinol stent for mechanical thrombectomy adapts to the unique anatomy of each patient, enhancing procedural success and reducing complications.

Research supports the effectiveness of nitinol stents in thrombectomy procedures. A retrospective multicenter study involving 141 patients reported an 83% success rate in achieving TIMI flow restoration. Good functional outcomes, defined as a modified Rankin Scale score of less than 2, were observed in 55% of patients. Another study by Castano et al. showed a 90% success rate in restoring blood flow, with 45% of patients achieving favorable outcomes at three months.

Study | Patients | TIMI Flow | Good Functional Outcomes |

|---|---|---|---|

Castano et al, 2010 | 20 | 90% (18/20) | 45% at 3 months |

2010 Report | 22 | 91% (20/22) | 66% improved by 10+ NIHSS |

Retrospective Multicenter Study | 141 | 83% (120/144) | 55% (mRankin < 2) |

The ability to customize nitinol stents for mechanical thrombectomy ensures that they meet the specific needs of each patient. This adaptability improves patient outcomes and establishes nitinol as a cornerstone of thrombectomy technology.

Real-World Success Stories in Neurovascular Treatments

Real-world applications of nitinol stents highlight their transformative impact on neurovascular care. In one documented case, a Fluency Plus stent-graft successfully treated a carotid artery injury. The stent covered the common carotid bifurcation and the proximal cervical segment of the left internal carotid artery. Following the deployment of two Precise nitinol stents across an iatrogenic dissection, control angiography revealed a near-normal caliber of the right common carotid artery. This outcome demonstrated the effectiveness of nitinol stents in restoring vascular integrity.

Another example involves the use of neurovascular flow-diverters to treat complex aneurysms. These devices, leveraging nitinol's unique properties, achieved complete occlusion in a majority of cases while maintaining blood flow in adjacent branches. Such success stories underscore the versatility of nitinol stents in addressing diverse neurovascular challenges.

The applications of nitinol stents continue to expand, driven by advancements in material science and customization technology. Their ability to improve patient outcomes while ensuring safety and reliability cements their role as a vital tool in neurovascular care.

Advantages of Customizable Nitinol Stents

Flexibility and Adaptability in Dynamic Environments

Customizable nitinol stents excel in dynamic vascular environments due to their unique properties. Their shape memory and superelasticity allow them to adapt to the constantly changing conditions within blood vessels. This adaptability ensures that the stents maintain their structure while accommodating the natural movements of the vascular system.

Flexibility is another critical advantage. Nitinol stents expand precisely within arteries, ensuring optimal blood flow. Mechanical testing has shown that nitinol outperforms stainless steel and titanium alloys in terms of flexibility. This superior performance makes nitinol stents particularly effective in complex vascular pathways, where precision is essential.

Evidence Description | Key Benefit |

|---|---|

Shape memory and superelasticity enable adaptation to dynamic environments. | Adaptability to varying conditions |

Flexibility ensures precise expansion within arteries. | Flexibility in dynamic environments |

Superior flexibility compared to other alloys. | Enhanced performance in complex pathways |

These characteristics make nitinol stents indispensable in minimally invasive procedures, where precision and adaptability are paramount.

Long-Term Durability and Patient Safety

Durability is a defining feature of nitinol stents. Their corrosion resistance ensures they remain intact within the body over extended periods. This property minimizes the risk of material degradation, which could compromise patient safety. Additionally, nitinol's biocompatibility reduces the likelihood of adverse reactions, further enhancing its suitability for implantation.

Studies have demonstrated that nitinol stents maintain their structural integrity even under continuous mechanical stress. This reliability is crucial for minimally invasive procedures, where long-term performance directly impacts patient outcomes. By combining durability with safety, nitinol stents provide a dependable solution for treating vascular conditions.

Enhanced Precision in Neurovascular Procedures

Nitinol stents offer unparalleled precision in neurovascular procedures. Their ability to conform to the intricate anatomy of the vascular system ensures accurate placement and effective treatment. This precision is particularly beneficial in minimally invasive procedures, where even minor deviations can have significant consequences.

The stents' superelasticity allows them to navigate complex vascular pathways with ease. This capability reduces the risk of complications during procedures, improving overall success rates. By enhancing precision, nitinol stents play a vital role in advancing neurovascular care and improving patient outcomes.

Future of Nitinol Stent Technology

Emerging Trends in Nitinol Stent Development

The development of nitinol stents continues to evolve, driven by advancements in technology and increasing demand for minimally invasive procedures. Several trends are shaping the future of this field:

Self-expanding and drug-eluting stents are becoming more prevalent, offering improved clinical outcomes and reduced restenosis rates.

Artificial intelligence and robotic-assisted systems are being integrated into stent placement, enhancing precision and reducing procedural risks.

The rising incidence of cardiovascular and peripheral artery diseases is fueling the need for innovative stent designs.

Bioresorbable stents and hybrid materials are emerging as promising alternatives, providing temporary support while minimizing long-term complications.

These innovations aim to improve patient recovery times and expand the applications of nitinol stents in neurovascular care.

Advancements in Material Science

Material science plays a pivotal role in enhancing the performance of nitinol stents. Recent advancements include:

Advancement Type | Description |

|---|---|

Innovative Surface Treatment Methods | Techniques like electropolishing and drug-eluting coatings improve corrosion resistance and reduce restenosis risks. |

Additive Manufacturing | 3D printing enables the creation of complex, patient-specific designs, enhancing customization and mechanical properties. |

Development of New Nitinol Alloys | New alloys with improved fatigue resistance and biocompatibility optimize stent performance in challenging environments. |

These breakthroughs ensure that nitinol stents remain durable, adaptable, and safe for long-term use in medical applications.

Overcoming Challenges in Neurovascular Applications

Despite their advantages, nitinol stents face challenges in neurovascular applications. Studies highlight areas for improvement:

Aspect | Findings |

|---|---|

Mechanical Safety | Devices perform well in slightly curved vessels but may encounter irregular tissue in-growth. |

Deployment Feasibility | Self-expanding mechanisms ensure conformal deployment, though precision in complex anatomies remains a focus. |

Biocompatibility | Tissue growth through microstructured stents indicates compatibility, but irregularities require further refinement. |

Areas for Development | 3D computational modeling and real-time monitoring could enhance device performance and procedural outcomes. |

Addressing these challenges through advanced modeling and monitoring techniques will further solidify nitinol stents as a cornerstone of neurovascular care.

Nitinol stents have redefined neurovascular care through their shape memory, superelasticity, and biocompatibility. These properties enable precise deployment, adaptability, and long-term durability. Their transformative impact is evident in clinical outcomes. For example, studies report recanalization rates of up to 100% and favorable functional outcomes in 55% of patients treated with nitinol stents.

Study/Trial | Sample Size | Recanalization Rate | mRS ≤ 2 Rate | Mortality Rate | In-Stent Restenosis |

|---|---|---|---|---|---|

SARIS trial | 20 patients | 100% (TIMI 2/3) | 55% | 35% | No |

Multicenter study | 1122 patients | 74% (multimodal therapy) | N/A | N/A | N/A |

Continued innovation in nitinol stent technology promises to address challenges and expand its applications, ensuring better outcomes for patients worldwide.

FAQ

What makes nitinol stents unique in neurovascular care?

Nitinol stents stand out due to their shape memory and superelasticity. These properties allow them to adapt to the dynamic environment of blood vessels. Their biocompatibility and corrosion resistance further enhance their suitability for neurovascular procedures.

How are nitinol stents customized for specific patients?

Manufacturers adjust the nickel-titanium ratio and apply heat treatments to program the stent's shape memory. Surface modifications improve biocompatibility, ensuring the stent meets individual patient needs and performs effectively in neurovascular applications.

Are nitinol stents safe for long-term use?

Yes, nitinol stents are highly durable and resistant to corrosion. Their biocompatibility minimizes adverse reactions, making them safe for long-term implantation in neurovascular and cardiovascular devices.

What role do nitinol stents play in treating aneurysms?

Nitinol stents provide structural support and regulate blood flow in aneurysm treatment. Flow-diverters, a specialized type of nitinol stent, reduce blood flow to aneurysms while maintaining circulation in nearby vessels, improving patient outcomes.

How do nitinol stents compare to other cardiovascular devices?

Nitinol stents outperform traditional cardiovascular devices in flexibility and adaptability. Their ability to conform to complex vascular pathways ensures precise placement and effective treatment, making them a preferred choice in vascular applications.

See Also

Nitinol Tubing's Impact on Modern Medical Innovations

A Comprehensive Process for Creating Nitinol Microtubing

Understanding Nitinol's Unique Properties: Shape Memory and Superelasticity