How to Find Custom Shape Memory Nitinol Tube Manufacturers

Choosing the right custom shape memory Nitinol tube manufacturers plays a critical role in ensuring project success. Manufacturers must meet stringent requirements for quality and precision, as these tubes often serve vital roles in medical and industrial applications. Key factors to evaluate include:

Testing: High-quality testing ensures the tubes are safe, flexible, and durable.

Manufacturing Capabilities: Advanced techniques and scalability support consistent performance.

Regulatory Compliance: Adherence to standards like ISO 13485 guarantees safety and reliability.

Additionally, a manufacturer’s history, customer reviews, and industry recognition can provide valuable insights into their expertise and reliability. Ignoring these factors can lead to delays, subpar products, or compliance issues, which may jeopardize your project.

Key Takeaways

Pick manufacturers that test well to ensure safe, strong tubes.

Clearly list your project needs, like size and material type.

Check if manufacturers follow rules like ISO 13485 and FDA standards.

Look at their skills in making tricky designs, like laser-cut tubes.

Review how they communicate and deliver on time for your project.

Define Your Project’s Nitinol Requirements

Specify the dimensions and properties of your Nitinol tubes

Defining the precise dimensions and properties of Nitinol tubing is essential for achieving optimal performance. Manufacturers require detailed specifications, including diameter, wall thickness, and length, to produce tubing that meets project needs. For example, Nitinol tubing can be customized with diameters as small as 0.25 mm or larger, depending on the application. Additionally, understanding material properties such as density (6.45 gm/cm³), ultimate tensile strength (1103 MPa to 1378 MPa), and elongation (>10%) ensures the tubing performs reliably under stress.

The active temperature range of Nitinol (-95 °C to 22 °C) is another critical factor, especially for applications requiring shape memory or superelasticity. Compliance with ASTM F2063 guarantees the tubing meets high-quality standards, particularly for medical device applications like stents and guidewires. Providing this technical data upfront helps manufacturers deliver precise and reliable custom nitinol tubing.

Determine the level of customization needed for your application

Customization plays a pivotal role in tailoring Nitinol tubing to specific project requirements. Applications in the medical field, such as minimally invasive devices, often demand unique designs and precise tolerances. Manufacturers capable of producing prototypes and complex geometries, such as laser-cut hypotubes, offer significant advantages.

Consider whether your project requires additional features, such as specific surface finishes or coatings, to enhance performance. Scalability is another important factor. Manufacturers should accommodate both small-batch prototypes and large-scale production runs without compromising quality. Collaborating with a supplier experienced in custom nitinol tubing ensures the final product aligns with your application’s unique demands.

Consider industry-specific standards and certifications

Industry standards and certifications are non-negotiable when selecting Nitinol tubing for critical applications. ISO 13485 certification demonstrates a manufacturer’s adherence to quality management systems tailored for medical devices. FDA compliance ensures the tubing meets regulatory guidelines, including 510(k) clearance for medical-grade products.

ASTM F2063 outlines the material properties and testing protocols for Nitinol, ensuring safety and reliability in biomedical applications. Manufacturers with these certifications provide added assurance of quality and regulatory compliance. Partnering with a certified supplier reduces risks and ensures the tubing meets the stringent requirements of medical device applications.

Assess Expertise in Custom Shape Memory Nitinol Tube Manufacturing

Look for manufacturers with extensive experience in Nitinol

Manufacturers with extensive experience in Nitinol production bring invaluable expertise to custom projects. Their familiarity with the material’s unique properties, such as shape memory and superelasticity, ensures consistent quality and performance. Companies like Dynalloy, EUROFLEX, and Fort Wayne Metals exemplify this expertise.

Manufacturer | Expertise Description |

|---|---|

Dynalloy | Recognized for producing nitinol tubing with high fatigue resistance, suitable for critical applications. |

EUROFLEX | Known for unparalleled customization and client-specific solutions in nitinol tubing production. |

Fort Wayne Metals | A global leader with extensive production capabilities, delivering high-quality nitinol tubing. |

Selecting manufacturers with proven track records reduces risks associated with material inconsistencies or design flaws. Their ability to meet stringent requirements for medical and industrial applications makes them ideal partners for custom nitinol tubing projects.

Evaluate their ability to produce nitinol laser cut hypotubes

The production of nitinol laser cut hypotubes requires precision and advanced technology. Manufacturers capable of delivering these components must demonstrate expertise in laser cutting techniques that ensure smooth edges, accurate dimensions, and minimal heat-affected zones. Quality control assessments further validate their capabilities:

Quality Control Assessment | Description |

|---|---|

Electropolishing | A final surface finishing step that eliminates heat affected zones, surface irregularities, and improves corrosion resistance. |

Automated Visual Inspection | System for dimensional measurement, data analysis, and archiving. |

Surface Preparation | Includes chemical cleaning, etching, and micro-blasting to ensure quality before final processing. |

Additional measures include:

Every lot comes with a Certificate of Conformance (CoC).

Material traceability is ensured with inspections upon arrival.

Cleaning and pickling processes follow ASTM A380 standards.

Manufacturers who adhere to these practices deliver nitinol laser cut hypotubes that meet the highest standards of precision and reliability. Their ability to produce these components is critical for applications requiring intricate designs, such as medical stents and catheter systems.

Check for in-house equipment and technical capabilities

In-house equipment and technical capabilities play a pivotal role in determining a manufacturer’s competence. Advanced machinery and testing facilities enable manufacturers to produce high-quality nitinol tubing and hypotubes with consistent results. Key evaluations include:

Evidence Type | Description |

|---|---|

Certifications | Certified under DIN, EN, ISO 9001, and ISO 13485 ensuring high product quality. |

Manufacturing Processes | Offers laser-cut tube components, shape-set Nitinol parts, and various surface finish options. |

Testing Capabilities | Conducts tensile, compression, hardness, corrosion, and fatigue testing using ASTM standards. |

Material Variability | Supplies Nitinol tubes in multiple conditions and surface finishes tailored to customer specifications. |

Research and Development Support | Collaborates on large development projects for next-generation alloys and components. |

Manufacturers equipped with state-of-the-art facilities can handle complex projects, from prototyping to large-scale production. Their ability to conduct rigorous testing ensures the tubing meets performance requirements under various conditions. Collaborating with manufacturers who invest in research and development further enhances innovation and product quality.

Ensure Quality Standards and Certifications

Verify compliance with ISO, FDA, or other relevant certifications

Compliance with industry standards and certifications is a cornerstone of high-quality nitinol tubing manufacturing. Manufacturers must adhere to globally recognized benchmarks to ensure product safety and reliability. Certifications such as ISO 13485 and FDA compliance validate that the production processes meet stringent regulatory requirements.

ISO 13485 establishes a comprehensive framework for meeting Quality Management System requirements in the design, manufacture, and distribution of medical devices. It is harmonized with global regulatory requirements, which facilitates compliance and certification across different regions.

Additionally, ASTM standards like ASTM F2633-07 and ASTM F2063 play a critical role in ensuring the tubing's chemical composition, mechanical properties, and fatigue resistance align with industry expectations. These certifications involve rigorous testing, including tensile strength assessments and thermal analysis, to confirm material performance.

Manufacturers should also provide certificates of analysis and material test reports. These documents offer transparency by detailing critical properties such as the nickel-titanium ratio and confirming adherence to industry standards. Partnering with certified manufacturers ensures that the nitinol tubing meets the highest safety and quality benchmarks.

Review their quality control processes and validation methods

A robust quality control process is essential for maintaining consistent performance in nitinol tubing. Manufacturers must implement comprehensive validation methods to ensure their products meet predefined standards. These methods typically include process design, qualification, and continuous verification.

Component/Stage | Description |

|---|---|

Validation Master Plan (VMP) | A comprehensive document summarizing the overall validation strategy across the organization. |

Process Design | The initial stage where the process is designed to meet quality standards. |

Process Qualification | Involves validating the process to ensure it performs as intended. |

Continuous Process Verification | Ongoing assessment to ensure the process remains in a validated state. |

Types of Process Validation | Includes Prospective, Concurrent, Retrospective, and Re-validation. |

Periodic Reviews | Reviews to assess if changes have affected manufacturing process performance. |

VMP Components | Includes Drug Products, Manufacturing Process, Validation Strategies, Protocols, and Reports. |

Change Control Procedures | Procedures to manage changes in process, product, or equipment. |

Supporting Data for Reviews | Data from BMR, Environmental Monitoring, Test Reports, and Quality Audit Records. |

These processes ensure that every stage of production aligns with the required standards. Manufacturers must also conduct periodic reviews to assess whether changes in equipment or processes have impacted product quality. By implementing these measures, manufacturers can guarantee the safety and reliability of their nitinol tubing.

Request samples or case studies to assess product quality

Requesting samples or reviewing case studies provides valuable insights into the quality of nitinol tubing. Samples allow for direct evaluation of key metrics such as tensile strength, strain amplitudes, and cycles to failure. For example, high-quality nitinol tubing often demonstrates tensile strength between 500 MPa and 900 MPa and can withstand up to 10⁷ cycles without failure.

Metric | Result |

|---|---|

Tensile Strength | 500 MPa to 900 MPa |

Local Strains | Up to 6% |

Cycles to Failure | Up to 10⁷ cycles |

Strain Amplitudes | 0.5% to 2.9% |

Cold Work Percentage | 20–30% |

Case studies further validate the manufacturer's expertise by showcasing real-world applications of their products. For instance, transformation temperature consistency and surface quality are critical for medical devices.

Ingot | Tube Lot | Processing Method | Transformation Temperature (°C) | Surface Quality |

|---|---|---|---|---|

1 | 1-1 | TM-1 | 20 ± 3 | High |

1 | 1-2 | TM-1 | 20 ± 3 | High |

2 | 2-1 | TM-1 | 20 ± 3 | High |

By analyzing these data points, project teams can make informed decisions about the suitability of a manufacturer’s nitinol tubing for their specific applications. This step ensures that the final product meets the required safety and performance standards.

Evaluate Customization and Production Flexibility

Assess their ability to create unique designs and prototypes

Manufacturers specializing in nitinol tubing must demonstrate the ability to create unique designs and prototypes tailored to specific applications. Advanced techniques, such as using low-cost polymeric cores and sacrificial fixtures, enable rapid prototyping of nitinol structures. This approach supports the development of individualized implants and complex shapes, showcasing the versatility of nitinol in medical applications. For instance, this method has been successfully applied to create a proof-of-concept for an individualized atrial occluder.

Additionally, companies offering end-to-end services, including design, validation, and contract manufacturing, provide significant advantages. These services streamline the development process, ensuring that prototypes meet precise specifications. Expertise in laser cutting, heat shaping, and surface finishing further enhances the ability to produce intricate designs. Manufacturers with these capabilities can deliver innovative solutions for Class II and Class III implantable devices, as well as catheter-based components.

Check for scalability to meet future production needs

Scalability is a critical factor when selecting a partner for nitinol tubing production. The global market for nitinol tubes is projected to grow from $250 million in 2022 to $400 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.5%. This growth highlights the increasing demand for nitinol in advanced technologies. Manufacturers must demonstrate the ability to scale production to meet this rising demand without compromising quality.

Advancements in manufacturing processes, such as additive manufacturing, play a pivotal role in enhancing scalability. These innovations reduce production costs and improve accessibility, making nitinol tubing viable for a broader range of industries. Furthermore, the rising demand for nickel, a key component of nitinol, underscores the importance of partnering with manufacturers capable of adapting to market trends and ensuring a steady supply chain.

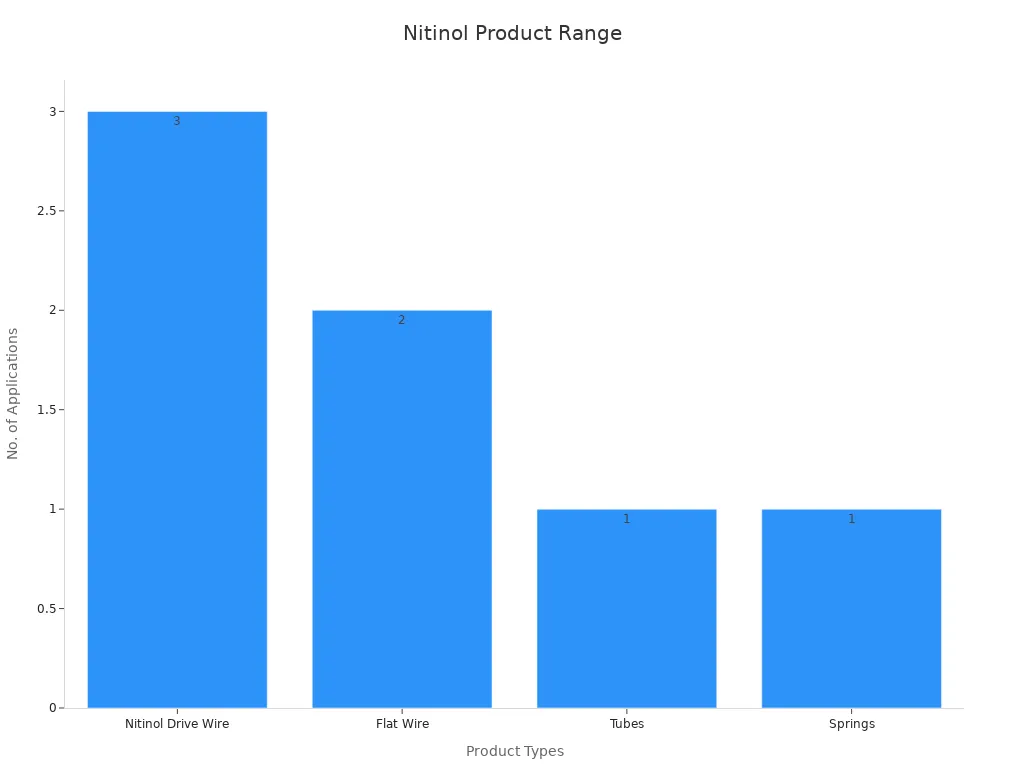

Explore their range of Nitinol products, including flat wire and complex shapes

A diverse product portfolio reflects a manufacturer’s expertise and flexibility in nitinol production. Leading manufacturers offer a wide range of nitinol products, including drive wires, flat wires, tubes, and springs. Each product type serves specific applications, from medical devices to robotics and aerospace.

Product Type | Description | Applications |

|---|---|---|

Nitinol Drive Wire | A wire made from nickel-titanium alloy, known for its shape memory and superelasticity. | Medical devices, aerospace, robotics |

Flat Wire | A flat version of nitinol wire, used in various applications requiring flexibility and strength. | Actuators, robotics |

Tubes | Hollow nitinol structures that can be used in medical devices and other applications. | Medical implants |

Springs | Nitinol springs that can return to their original shape after deformation. | Various mechanical applications |

This variety ensures that manufacturers can meet the unique requirements of different industries. For example, nitinol tubing is essential for medical implants, while flat wires and springs find applications in robotics and actuators. The ability to produce such a diverse range of products demonstrates a manufacturer’s technical capabilities and commitment to innovation.

Compare Communication, Pricing, and Lead Times

Evaluate responsiveness and transparency in communication

Effective communication is a cornerstone of successful partnerships with nitinol manufacturers. Responsiveness and transparency ensure that project requirements are understood and met without delays. Manufacturers that prioritize open communication often implement practices such as:

Regular updates and information sharing with supply chain partners.

Hosting supplier conferences to encourage direct dialogue and feedback.

Providing dedicated supplier web pages with policies, compliance documents, and FAQs for easy access.

These measures foster trust and streamline collaboration, reducing the risk of miscommunication. Companies that demonstrate a commitment to transparency and responsiveness are better equipped to address challenges promptly, ensuring smooth project execution.

Compare pricing structures and overall value for money

Pricing plays a critical role in selecting the right nitinol supplier. However, focusing solely on cost can compromise quality. A comparative analysis of pricing structures helps identify suppliers that offer the best value for money.

Supplier | Price Competitiveness | Quality Focus |

|---|---|---|

AccuPath | Best price for OD 2mm tubing | High quality without compromise |

Tech Tube | Competitive pricing | Specializes in niche applications |

Johnson Matthey Medical | Good prices | Focus on specialized uses, potentially higher for standard tubing |

Understanding how pricing reflects material quality and customization options is essential. Suppliers like AccuPath balance affordability with high standards, making them ideal for projects requiring precision and reliability. Evaluating these factors ensures that budgetary constraints align with sourcing high-quality nitinol materials.

Assess lead times and delivery reliability for your project

Timely delivery is crucial for maintaining project timelines, especially for custom nitinol tube projects. Manufacturers with substantial production capacity can better handle fluctuating demands, ensuring consistent supply. Reliable suppliers provide realistic lead time estimates and maintain a proven track record of meeting delivery commitments.

For instance, companies with advanced manufacturing capabilities can adapt to changing requirements without compromising quality. This reliability minimizes delays and ensures that projects progress as planned. Selecting a supplier with dependable delivery performance safeguards against disruptions, keeping operations on schedule.

Selecting the right custom shape memory nitinol tube manufacturers is essential for ensuring project success. Key factors include expertise in nitinol, adherence to quality standards, and the ability to meet unique customization needs. Balancing these criteria with cost considerations helps achieve optimal results without compromising performance.

AccuPath stands out as a reliable partner for nitinol solutions. Their expertise in producing nitinol laser cut hypotubes and other custom components ensures precision and quality. Consulting with experienced manufacturers like AccuPath can streamline the process and deliver superior outcomes for your project.

FAQ

What is the typical lead time for custom Nitinol tubing?

Lead times vary depending on the complexity of the design and production capacity. Most manufacturers deliver custom Nitinol tubing within 4 to 8 weeks. For urgent projects, some suppliers offer expedited services.

How can manufacturers ensure the biocompatibility of Nitinol tubing?

Manufacturers ensure biocompatibility by adhering to ASTM F2063 standards and conducting rigorous testing. Processes like electropolishing and surface passivation enhance corrosion resistance, making the tubing suitable for medical applications.

Are prototypes available before full-scale production?

Yes, most manufacturers provide prototypes to validate designs before mass production. Prototyping allows clients to test functionality and make adjustments, ensuring the final product meets application requirements.

What industries commonly use custom Nitinol tubing?

Custom Nitinol tubing is widely used in medical devices, aerospace, robotics, and automotive industries. Its shape memory and superelastic properties make it ideal for stents, catheter systems, actuators, and other precision components.

How does pricing vary for custom Nitinol tubing?

Pricing depends on factors like dimensions, customization level, and order volume. Complex designs and smaller batches typically cost more. Manufacturers often provide detailed quotes based on project specifications.