What Custom Nitinol Tubing Means for Neurovascular Catheters

Custom nitinol tubing for neurovascular catheters uses a nickel-titanium alloy. This alloy is made for accuracy and good performance in blood vessel procedures. Nitinol is special in medical devices because it is very bendy, keeps its shape, and works well with the body. Makers keep the sizes very exact, as shown below:

Parameter | Statistic |

|---|---|

OD Tolerance | ±0.005 mm (small diameters) |

Fatigue Life | Up to 10^7 cycles |

Surface Roughness | ~0.15 µm after polishing |

These things make custom nitinol tubing for neurovascular catheters safe and dependable during hard procedures.

Key Takeaways

Custom nitinol tubing is very flexible and strong. It lets neurovascular catheters bend in small, twisty blood vessels. The tubing does not kink or break when it bends.

Special steps like laser cutting and electropolishing make the tubing smooth and exact. This helps the tubing move easily and last longer in the body.

Nitinol tubing does not rust and works well with the body. This lowers the chance of tissue damage or allergic reactions. It is safe for most patients.

Nitinol tubing has better shape memory and superelasticity than stainless steel. This makes it easier to control the catheter and helps patients get better results.

Nitinol tubing is strong and can be made in custom sizes. This helps doctors do safer and more exact neurovascular procedures. It also leads to more success and fewer problems.

Custom Nitinol Tubing for Neurovascular Catheters

What Is Nitinol Tubing

Nitinol tubing is used in many new neurovascular catheters. It is made from a nickel-titanium alloy. This alloy has special features that other metals do not have. To make nitinol tubing, manufacturers melt nickel and titanium together. They use special methods like vacuum induction melting and vacuum arc remelting. These methods help keep the tubing very pure and high quality. The finished tubing usually has an austenite finish temperature close to 20 ± 3 °C. This means it can change shape at body temperature and then go back to its original shape.

Scientists have looked closely at nitinol tubing. They check things like grain size, inclusion density, and surface defect size. These things affect how the tubing works inside the body. Smaller inclusions and fewer defects help the tubing last longer. After making the tubing, manufacturers use polycrystalline diamond dies and vacuum annealing. This keeps the tubing smooth and pure. Electropolishing takes away tiny flaws on the surface. This makes the tubing even safer for medical use.

Nitinol tubing is special because it is strong, flexible, and can return to its shape after bending. This is very important for neurovascular catheter nitinol tubing, where safety and performance matter a lot.

Customization for Catheter Use

Custom nitinol tubing for neurovascular catheters needs more than just the right alloy. Manufacturers use special techniques to meet the needs of these procedures. Some of these techniques are:

Precision laser cutting makes tubing with tight tolerances and smooth surfaces. This helps the tubing move easily through small blood vessels.

Laser-cut hypotubes add tiny, complex features. These features help the catheter bend and move better inside the body.

Electropolishing removes stress points and helps stop corrosion. This makes the tubing last longer in the body.

Hydrophilic and biocompatible coatings make the tubing slippery and safe for tissue. These coatings help the catheter slide and protect tissue from harm.

Custom sizing makes sure the tubing fits the body’s needs. This keeps the tubing strong and flexible, even when stressed.

Uniform wall thickness gives the tubing even strength and flexibility. This is important for custom nitinol tubing for neurovascular catheters.

These steps help nitinol tubing meet the tough standards for neurovascular use. The tubing must bend to move through tricky blood vessels. It also needs to be strong enough to support devices like stents and flow diverters. Custom nitinol tubing for neurovascular catheters gives both strength and flexibility. This makes it a great choice for today’s neurovascular procedures.

Key Properties of Nitinol Tubing

Shape Memory and Superelasticity

Nitinol is special in medical devices because it can remember its shape. It can bend or stretch and then go back to how it was before. This is very important for neurovascular catheters. When nitinol is under stress at body temperature, it changes from austenite to martensite. This change lets the tubing stretch up to 4% and then return to normal when the stress stops. Nitinol does not need heat to get its shape back during superelastic use. Other metals cannot do this.

Scientists have tested these features in labs. The table below shows what they found:

Metric / Observation | Description / Value |

|---|---|

Strain rates | Range from very slow ( |

Stress level for transformation | Around 200 MPa |

Superelastic strain limit | Up to 4% strain at 37 °C with a stress plateau |

Fatigue testing | Ultrasonic fatigue tests simulate millions of cycles |

Maximum mean strain | Up to 4% with max strain amplitude of 2.25% |

These results show nitinol tubing can bend and stretch many times without breaking. Medical stents made from nitinol can last through 400 million pressure cycles. This strength comes from superelasticity and the way nitinol absorbs and releases energy each time it bends.

Corrosion Resistance and Biocompatibility

Nitinol tubing does not rust easily and is safe for the body. Special surface treatments like electropolishing and passivation make the titanium oxide layer thicker. This layer stops nickel from leaking out and keeps the tubing safe from rust.

Salt spray tests show nitinol tubing does not rust in tough places.

Electropolished nitinol can handle up to 1000 mV before breaking down, which means it is strong against chemicals.

Lab and animal tests show treated nitinol does not hurt tissue.

Fast durability tests show nitinol tubing can last for years.

Meeting ASTM F2063 and FDA rules means nitinol tubing is safe for medical use.

These things make nitinol a great choice for neurovascular catheters. Its rust resistance and safety help lower risks and make patients safer.

Benefits in Neurovascular Catheters

Flexibility and Kink Resistance

Nitinol gives neurovascular catheter nitinol tubing both flexibility and kink resistance. Doctors use catheters to reach tiny, twisty blood vessels in the brain. Nitinol tubing bends easily and goes back to its shape after many uses. This helps stop kinks or blockages that could hurt blood flow or damage vessels.

Nitinol tubing can bend from 0° to 180° many times and not break.

Superelasticity and shape memory let the tubing flex and recover, which is important for safe use.

Lab tests show nitinol tubing lasts through millions of bends without failing.

Clinical studies show a 97% success rate and only about 4.1% complications with nitinol-based catheters.

Doctors notice better control and fewer problems in neurovascular procedures.

Nitinol guidewires and catheters keep their shape under pressure. This lowers breakage and helps them work better during tough neurovascular procedures.

Surface treatments like electropolishing make kink resistance and biocompatibility even better. These features make nitinol tubing a top pick for strengthening catheters in neurovascular uses.

Precision and Minimally Invasive Use

Custom nitinol tubing for neurovascular catheters helps doctors do very precise and less invasive procedures. The tubing’s superelasticity and shape memory let engineers make very thin, flexible devices. These devices can move through the smallest blood vessels without hurting them.

Thin film nitinol lets engineers design very small catheters.

Customizing diameter, wall thickness, and transformation temperature makes sure each catheter fits its job.

Advanced manufacturing, like laser cutting and surface finishing, creates detailed and accurate parts.

Careful quality checks make sure the tubing stays superelastic and resists fatigue.

These features help make self-expanding superelastic nitinol stents and flow-diverters. These devices can go through small tubes, so procedures are less invasive and safer for patients.

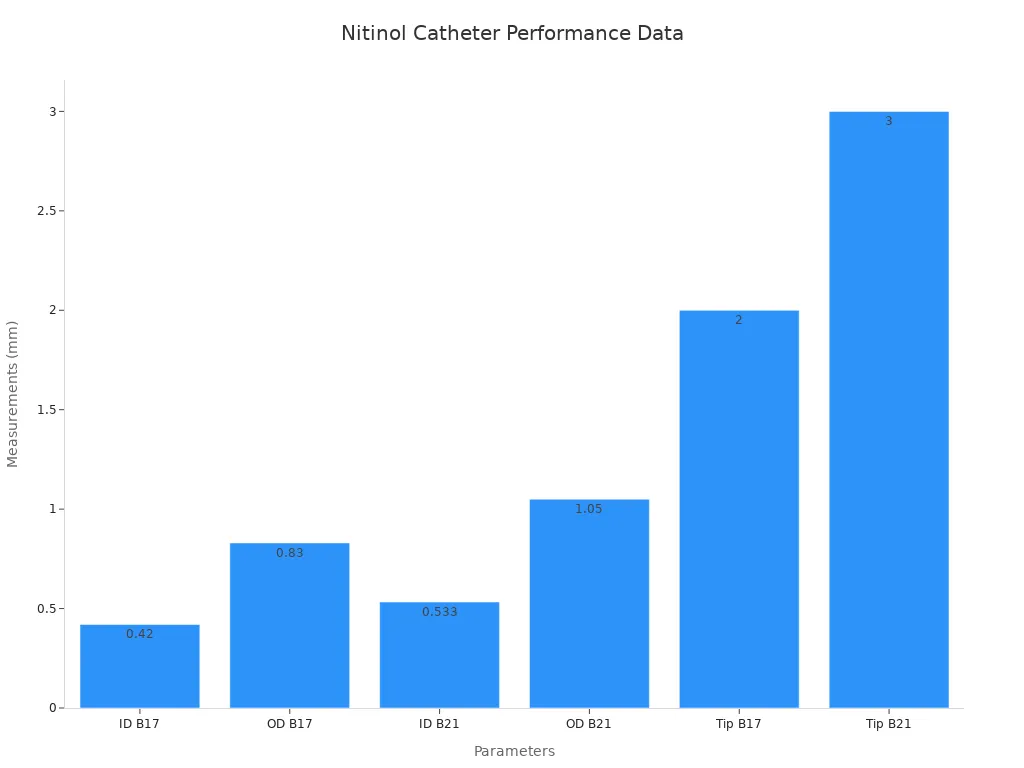

Parameter | Measurement | Significance for Performance |

|---|---|---|

Inner diameter Bendit 17 | 0.0165 inches (0.42 mm) | Good for smaller vessels |

Outer diameter Bendit 17 | 2.5 F (0.033 inches / 0.83 mm) | Small size for neurovascular navigation |

Inner diameter Bendit 21 | 0.021 inches (0.533 mm) | Lets devices go into bigger vessels |

Outer diameter Bendit 21 | 3.1 F (0.041 inches / 1.05 mm) at second marker; narrows to 2.9 F distally | Gives flexibility and support |

Tip bending radius | 180° over 2 mm (Bendit 17) or 3 mm (Bendit 21) | Allows the tip to bend for better navigation |

Average force to keep tip aligned | 0.244 N ± 0.041 N | Shows the tip stays steady during use |

Maximum force (95/90 confidence) | 0.329 N | Makes sure the tip stays stable under stress |

Torsional rigidity | One-to-one torsional rigidity | Helps doctors control the catheter exactly |

These numbers show how neurovascular catheter nitinol tubing helps doctors move catheters exactly where they need to go. The self-expanding design of nitinol stents and flow-diverters lets doctors place them accurately and keeps patients safer.

Durability and Patient Outcomes

Nitinol is very strong and lasts a long time in neurovascular catheters. The tubing does not get tired or lose its shape, even after millions of uses. This makes device failure and vessel injury less likely.

Clinical data shows that neurovascular catheters with nitinol tubing help doctors succeed about 25% more often. Problems drop by almost 20% compared to older materials. These changes make surgeries safer, help patients heal faster, and lower the chance of bad events.

Durability tests show nitinol tubing can handle up to 10 million bends without losing shape or strength. The tubing’s biocompatibility and corrosion resistance lower the chance of immune problems and vessel injury. This means blood vessels stay open longer and there are fewer cases of restenosis.

Nitinol’s long-lasting strength helps advanced devices like self-expanding stents and flow-diverters. These tools let doctors treat tough neurovascular problems with more confidence and better results.

Custom nitinol tubing for neurovascular catheters, with its tiny sizing and special coatings, makes sure each device works its best. The mix of flexibility, accuracy, and strength makes nitinol the best choice for today’s neurovascular procedures.

Nitinol Tubing vs Other Materials

Stainless Steel Comparison

Stainless steel is often used in medical devices like catheters and stents. It is strong and does not rust easily. But nitinol tubing has more benefits for neurovascular uses. Nitinol can bend and twist, then return to its shape. This helps doctors move devices through tiny, delicate brain vessels.

A study looked at nitinol and stainless steel stents in blood vessels. Nitinol stents caused fewer blood clots than stainless steel ones. Nitinol lowered fibrin and platelet buildup by over 35%. This means nitinol stents are less likely to block blood flow. They are safer for patients.

Nitinol does not get tired or break as fast as stainless steel. Nitinol devices can bend and stretch millions of times without breaking. Stainless steel is strong but not as flexible or tough as nitinol. Nitinol is also safe for the body and does not rust, which is good for long-term use.

Material | Key Advantages | Key Limitations | |

|---|---|---|---|

Nitinol Tubing | 500 - 900 | Superelasticity, shape memory, biocompatibility, corrosion resistance, flexibility, fatigue resistance | Higher cost, limited machinability |

Stainless Steel | Up to 1100 | High strength, corrosion resistance, durability | Heavier, less flexible, variable cost |

Unique Advantages for Catheters

Nitinol tubing gives special benefits to neurovascular catheters that other materials do not.

Superelasticity lets catheters bend through tight, twisty vessels without kinking.

Shape memory helps stents open up right where they are needed.

Biocompatibility lowers the chance of swelling or rejection.

Fatigue resistance means devices last longer, even with lots of movement.

Seamless tubing gives even strength, which is important for careful procedures.

Careful manufacturing makes sure each catheter is high quality.

Custom nitinol tubing helps make advanced tools like flow diverters and aneurysm occlusion devices. The tubing can gently press against vessel walls to lower injury risk. These features make nitinol the best choice for neurovascular catheters. It helps doctors do better procedures and keeps patients safer.

Safety and Limitations

Nickel Allergy and Biocompatibility

Nitinol tubing works well with the body, but nickel can cause allergies. Most people do not have problems with nitinol devices. Studies show even people with nickel allergies rarely have issues after getting nitinol neurovascular devices. For example, seven patients with metal allergies got nitinol brain devices and had no allergic reactions or tissue harm. Bigger studies also show serious allergies are rare, even without extra steps.

Still, about 17.5% of people are sensitive to nickel, as patch tests show. More than half of these cases matter for health. Nitinol can let out a little nickel, especially if the surface is thin or scratched. Studies on nitinol wires show small to medium effects over 30 days, likely from nickel release. Makers use treatments like passivation, electropolishing, and titanium oxide coatings to lower this risk.

Rules require careful testing for rust and nickel release. Standards like ASTM F2129 and ISO 10993 guide these tests. The FDA also asks for risk checks and clear labels for devices used a long time.

Tests for rust and nickel release use ASTM F2129, F3306, and G31.

How smooth and pure the surface is affects rust and nickel release.

Lab tests help, but animal and human studies give the best safety info.

Risk checks include reviews of toxins and tests for each device.

Longevity and Risks

Nitinol tubing lasts a long time and is safe in neurovascular catheters. Its shape memory and superelasticity help it bounce back after bending, so devices last longer. The titanium oxide layer stops rust and lowers nickel release, which helps it stay safe in the body.

Feature | Slotted Tube Stent | Woven Nitinol Stent | Why It Matters for Buyers |

|---|---|---|---|

Material | Stainless steel / Co-Cr | Nickel-Titanium (Nitinol) | Nitinol's shape memory makes it worth more |

Flexibility | Rigid (low rating) | Ultra-Flexible (high rating) | Needed for twisty blood vessels |

Radial Strength | Very High | Moderate | Slotted tubes are better for tough blockages |

MRI Compatibility | May cause artifacts | MRI-safe (FDA-approved) | Lets doctors do scans over time |

Lifespan | 5-10 years | Over 10 years | Means it lasts a long time |

Best Applications | Coronary arteries | Peripheral, neurovascular | Picks the right stent for the right place |

Nitinol stents and catheters can handle over 10 million bends. No nitinol heart devices have been taken out because of allergies. Surface treatments make nickel release even less likely. While more research is needed for long-term effects, current data shows nitinol is safe and works well for neurovascular use. 🛡️

Custom nitinol tubing is the best pick for neurovascular catheters. Its shape memory, superelasticity, and biocompatibility help doctors work safely. These features make procedures better and safer for patients. People have fewer problems and heal better.

Future changes may include:

Ultra-thin-walled tubing for more flexibility and strength

New coatings to make devices safer

Smart devices with nitinol for better control in blood vessels

These new ideas will help doctors give even better care and make devices work better.

FAQ

What makes nitinol tubing ideal for neurovascular catheters?

Nitinol tubing can bend and return to its shape. This helps catheters move through tiny, twisty blood vessels. Doctors like nitinol because it is strong and flexible.

Nitinol tubing lets doctors do safer and more exact procedures.

Can nitinol tubing cause allergic reactions?

Most people do not have allergies to nitinol tubing. Makers add coatings and treatments to stop nickel from coming out.

Studies show that even people with nickel allergies rarely have bad reactions.

How does nitinol tubing improve patient outcomes?

Nitinol tubing does not kink or wear out fast. Devices last longer and work better.

Patients heal faster

There are fewer problems

Doctors succeed more often

What custom options exist for nitinol tubing in catheters?

Makers can change the size, wall thickness, and add special coatings. Laser cutting makes tiny, exact shapes.

Customization | Benefit |

|---|---|

Sizing | Better fit |

Coatings | Improved safety |

Laser cuts | Enhanced control |

See Also

The Importance Of Nitinol Tubing In Modern Medical Use

The Process Behind Producing Nitinol Tubing For Healthcare

Nitinol Tubing’s Contribution To Progress In Medical Tech

Ways Nitinol Tubing Is Transforming Medical Device Innovation

Nitinol Tubing’s Critical Role In Minimally Invasive Surgery