Why Custom Extruded Nitinol Tubing Is Essential for Your Next Medical Device Project

Custom extruded nitinol tubing helps new ideas in medicine. It gives your device great flexibility, strength, and works well with the body. Custom nitinol tubing lets you make tubing for each patient and tricky shapes. More people want patient-specific solutions, so more extrusion-based tubing is used. In 2022, 55% of medical projects used extrusion technology. Nitinol tubing helps keep patients safe, works better, and follows tough safety rules. Medical teams trust custom extruded nitinol tubing for strong tubing, better safety, and new designs.

Key Takeaways

Custom extruded nitinol tubing is strong and bends easily. This makes medical devices safer and work better in the body. Nitinol tubing can remember its shape and does not bend too much. This helps devices move through small spaces without breaking. The tubing is safe for patients because it does not rust. It also lets out very little nickel, so there are fewer risks and healing is better. Good custom tubing follows strict medical rules and has important certificates. This makes sure it is always safe and works well. Custom tubing can be made in exact sizes and special shapes. This helps make devices for each patient and gives better treatment results.

Nitinol Tubing Properties

Superelasticity & Shape Memory

You want your medical device to work well every time. Nitinol tubing helps you feel sure about that. This material is special because it remembers its shape and is very bendy. If you bend or twist nitinol tubing, it goes back to how it was before. This lets your device move through small spaces in the body and still keep its shape.

Nitinol tubing works because of how its atoms are arranged. When you heat or cool the tubing, it changes its form. If the tubing is cold, you can bend it, and when it gets warm, it goes back to its old shape. This is called the shape memory effect. When it is warmer, nitinol tubing becomes superelastic. You can stretch or squeeze it, and it will not break or stay bent.

Devices like self-expanding stents use this to open blocked blood vessels. Nitinol tubing keeps its shape and works well even after being bent many times.

Tests show these features are real. The Bend Free Recovery test checks if the tubing goes back to its shape after bending and heating. Differential Scanning Calorimetry finds the exact temperature when the tubing changes form. These tests make sure your nitinol tubing will work as it should inside the body.

Here is how nitinol compares to other materials:

Material | Tensile Strength Range (MPa) | Unique Characteristics |

|---|---|---|

Nitinol Tubing | 500–900 | Shape memory and super-elasticity |

Stainless Steel | 600–1100+ | Versatile, strong |

Titanium Alloys | 900–1200 | Lightweight, strong |

Nitinol tubing is not the strongest, but it can go back to its shape and does not get bent out of shape. This makes it great for devices that need to bend and move.

Biocompatibility & Corrosion Resistance

You want your device to be safe for people. Nitinol tubing is very safe and does not rust easily. The outside of nitinol tubing has a thin layer of titanium oxide. This layer keeps the tubing safe from body fluids and stops bad nickel ions from coming out.

Studies show nitinol tubing lets out very little nickel, much less than what the FDA says is safe. Plasma-treated nitinol makes thinner capsules in the body, so there is less reaction and better healing. Devices with nitinol tubing last longer and fit better, so people need fewer repeat surgeries.

Let’s look at some important safety facts:

Metric | Result for Plasma-Treated Nitinol Surfaces |

|---|---|

Capsule Thickness | Thinner capsules, less tissue reaction |

Fibronectin Adsorption | Lower, less immune response |

Cell Penetration | More fibroblasts, better integration |

Blood Absorption Time | Faster, improved surface properties |

BSA Adsorption | Slightly reduced, variable impact |

Nitinol tubing also works well in tough places inside the body. It does not rust as much as stainless steel and is a lot like titanium alloys. Here is a table to compare them:

Material | Corrosion Resistance Characteristics | Relevant Unique Properties |

|---|---|---|

Nitinol | Excellent in harsh body fluids; surface treatments reduce nickel ion release | Superelasticity, shape memory, biocompatibility |

Stainless Steel | Good, but less effective at reducing nickel ion release | Moderate corrosion resistance |

Titanium Alloys | Great resistance, strong and lightweight but lacks superelasticity | High strength, lightweight |

You can count on nitinol tubing to keep your device safe and strong for a long time. Its mix of safety and not rusting makes it the best choice for new medical devices.

Custom Extruded Nitinol Tubing Benefits

Flexibility & Strength

Medical devices must work in hard-to-reach places. Custom extruded nitinol tubing helps with this. It bends and twists but does not break or lose shape. The tubing moves through tight spaces and goes back to its shape. This tubing is special because it is both bendy and strong.

Custom extrusion makes tubing fit your needs. You can get tubing with very thin walls. The tubing can be made very exact, even to ±0.005 mm. This means your device fits well and works right. Making the tubing without seams and using cold working makes it stronger and more flexible. High-quality nitinol tubing can handle high pressure and tough jobs.

Testing makes sure the tubing is safe and works well. For example, finite element analysis shows nitinol tubing can shrink up to 40% of its width and not break. It can take a lot of stress, especially where it bends. Polycrystalline nitinol can stretch up to 8% and still go back to normal. This keeps your device strong and bendy, even after many uses.

Tip: Pick custom extruded nitinol tubing for devices that must bend and stay strong. You get the best mix of bendiness, strength, and safety.

Fatigue Resistance

Devices need to last a long time. Good nitinol tubing is very tough. It does not wear out fast. It can handle millions of bends without breaking. Tests show nitinol tubing can last over 10 million bends at certain stress levels. Most pieces do not break unless the stress is very high. This makes nitinol tubing great for stents, heart valves, and other moving devices.

Nitinol changes shape at the atomic level. This lets it recover from big bends. This special property keeps the tubing strong and in shape after many bends. Making the tubing with heat and cold work makes it last even longer. Your device will work well for years.

Tubing Lot | Fatigue Life (Cycles) | Observations |

|---|---|---|

Lot 1−1 | >10^7 cycles | Very few fractures in high-cycle fatigue region |

Lot 1−2 | >10^7 cycles | Very few fractures in high-cycle fatigue region |

Lot 2−1 | >10^7 cycles | Very few fractures in high-cycle fatigue region |

You can trust good nitinol tubing to meet your project’s needs. Its toughness means fewer replacements and safer patients.

Regulatory Compliance

Devices must follow all safety rules. Custom extruded nitinol tubing helps you do this. The tubing is checked for quality at every step. Tests like ultrasonic and eddy current testing find any problems before you get the tubing. Surface steps like electropolishing and passivation make the tubing safer for the body.

Certifications like ISO 13485 show the tubing meets top medical rules. The tubing can pass FDA approval and CE marking. This means it is safe around the world. Quality checks and software keep every batch the same. Surface finish numbers, like Ra values as low as 0.21–0.25 µm, mean the tubing is smooth and safe.

Compliance Metric / Quality Measure | Description |

|---|---|

ISO 13485 Certification | Makes sure all steps meet strict medical device safety and quality rules, including risk checks, plans, and tests. |

FDA Approval and CE Marking | Shows the tubing meets world safety rules. |

Quality Control Measures | Tests to check product safety and standards. |

Statistical Process Control (SPC) | Watches production data to keep tubing size and quality the same. |

Surface Finish Metrics (Ra and RMS values) | Numbers that show how smooth the tubing is, which is important for safety and not rusting. |

Material Purity (High-Purity ELI Nitinol) | Makes sure there are few flaws and long life, so it does not fail. |

Biocompatibility and Corrosion Resistance Tests | Checks that tubing is safe in the body and does not break down. |

Certifications like ISO 13485 and FDA rules help you feel safe. You know your nitinol tubing follows all the rules. Testing makes sure it is safe for every patient.

Note: Always pick nitinol tubing from suppliers with ISO 13485. This makes sure your tubing meets the highest rules for safety, quality, and performance.

Customization & Advanced Tubing Solutions

Complex Shapes & Patient-Specific Designs

You want your device to fit each patient well. Custom tubing helps you make shapes for different bodies. You can use fast prototyping and special shape-setting to form springs, frames, or coils. Engineers use 3D-printed parts and copper tubes to shape tubing for each patient. After shaping, they take away the tools and test the tubing in real life. Benchtop tests show tubing can move through catheters and expand when needed. This process lets you change designs quickly and test them fast, so patients get better care.

Here are some important facts about advanced customization:

Metric/Aspect | Description/Impact | Outcome/Benefit |

|---|---|---|

Recovery Improvement | 20% faster recovery with nitinol devices | Quicker patient healing and comfort |

Risk of Complications | Lower risk due to biocompatibility and corrosion resistance | Enhanced patient safety |

Fatigue Life | High-cycle fatigue strain limits and improved cleanliness | Increased device durability and reliability |

Clinical Trials | Validated stent performance in complex treatments | Proven effectiveness |

Design Versatility | Patient-specific designs and low-cost prototyping | Tailored implants improving precision |

Integration with Nitinol Laser Cut Hypotubes

You can make your device work better by using nitinol laser cut hypotubes with tubing. These hypotubes have thin walls, exact slots, and high strength. You get tubing that bends, does not kink, and stays strong. Laser cut hypotubes help your device move easily in the body and stay tough. You can use laser welding to join tubing and hypotubes, keeping the device solid. Laser cut hypotubes also make your device smaller and the inside bigger, so it works better.

Nitinol laser cut hypotubes give superelasticity and shape memory, so your device bends and returns to shape.

Laser cut hypotubes can have walls as thin as 0.002", making them flexible and strong.

Tensile strength goes from 150 kpsi to 350 kpsi, giving strong results.

Advanced laser cut hypotubes help you build devices fast and save money.

Good nitinol laser cut hypotubes make sure your device meets strict quality rules.

You can trust tubing and laser cut hypotubes to give great results for your project.

Precision & Dimensional Control

You need tubing that is the right size and shape. Custom tubing uses special tools to keep sizes exact. Laser micrometers check the outside, and bore gauges check the inside. Optical comparators and ultrasonic gauges make sure every tube matches your design. You can get tubing with tolerances as tight as ±0.005mm for small sizes. This control means your tubing will always fit and work as planned.

Certified extrusion suppliers are important for quality. They use Statistical Process Control to watch every step. They follow rules like ISO 13485 and ASTM F2063, so your tubing is safe and reliable. Real-time checks and multi-pass drawing keep tubing the same and lower defects. You get tubing with steady shape memory and superelasticity, helping your best designs.

Tip: Work with skilled suppliers who use new technology. You will get tubing and laser cut hypotubes that meet top quality rules and help you create new ideas faster.

Medical Device Applications

Cardiovascular Devices

You want your medical tools to help people and work well. Custom extruded tubing is important for heart devices. You can use tubing in stents, heart valves, and guidewires. These tools must bend and stay strong inside blood vessels. Tubing with shape memory and superelasticity helps open blocked arteries. It also fits each patient’s vessel.

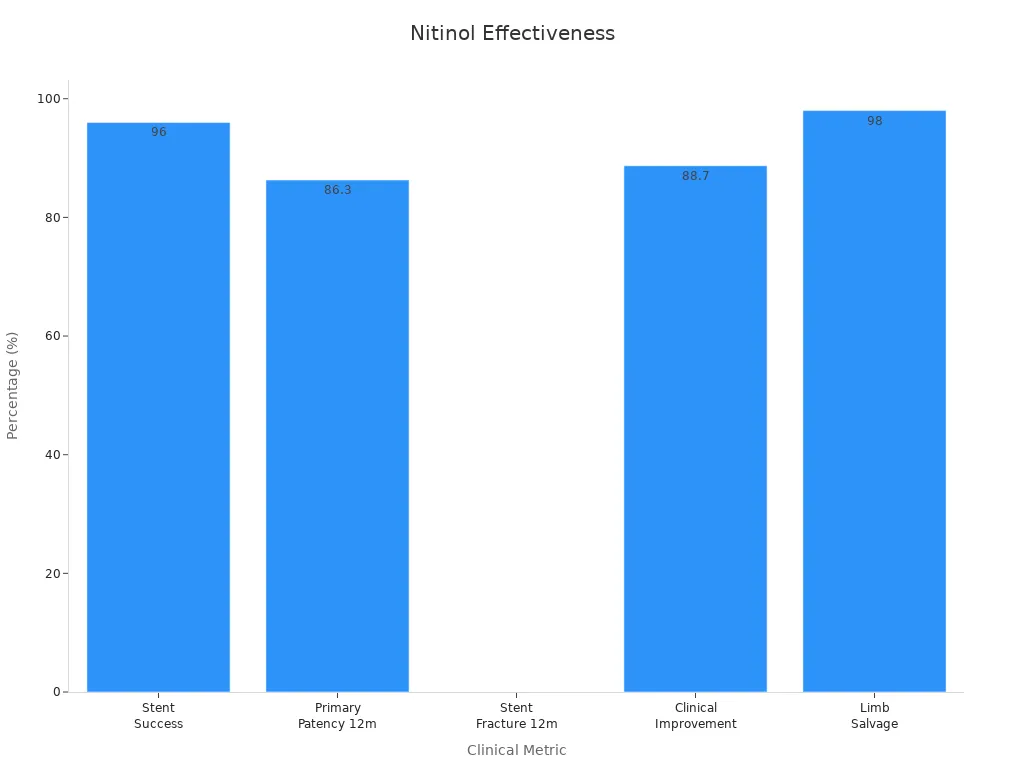

Clinical trials show tubing works well for these tools. Nitinol stents have up to a 96% success rate. After 12 months, patency rates can reach 86.3%. Stent fracture rates are zero, and 88.7% of patients get better. Limb salvage rates are as high as 98%. Your device will last longer and resist rust better than stainless steel.

Clinical Metric | Result/Outcome |

|---|---|

Nitinol Stent Success Rate | Up to 96% |

Primary Patency Rate at 12 months | Up to 86.3% |

Stent Fracture Rate at 12 months | 0% |

Clinical Improvement at 12 months | 88.7% of patients |

Limb Salvage Rate (Nitinol) | 98% |

Technical Success Rates in Studies | 87%–98% |

Fatigue Resistance | Up to 400 million cycles |

Comparative Durability (Nitinol vs Stainless Steel) | Nitinol lasts about 1880 minutes, stainless steel lasts 893 minutes |

Corrosion Resistance (Time to First Corrosion) | Nitinol: 908 minutes, Stainless Steel: 325 minutes |

Pick tubing for your heart tools to make them safer, stronger, and better for patients.

Neurovascular & Minimally Invasive Tools

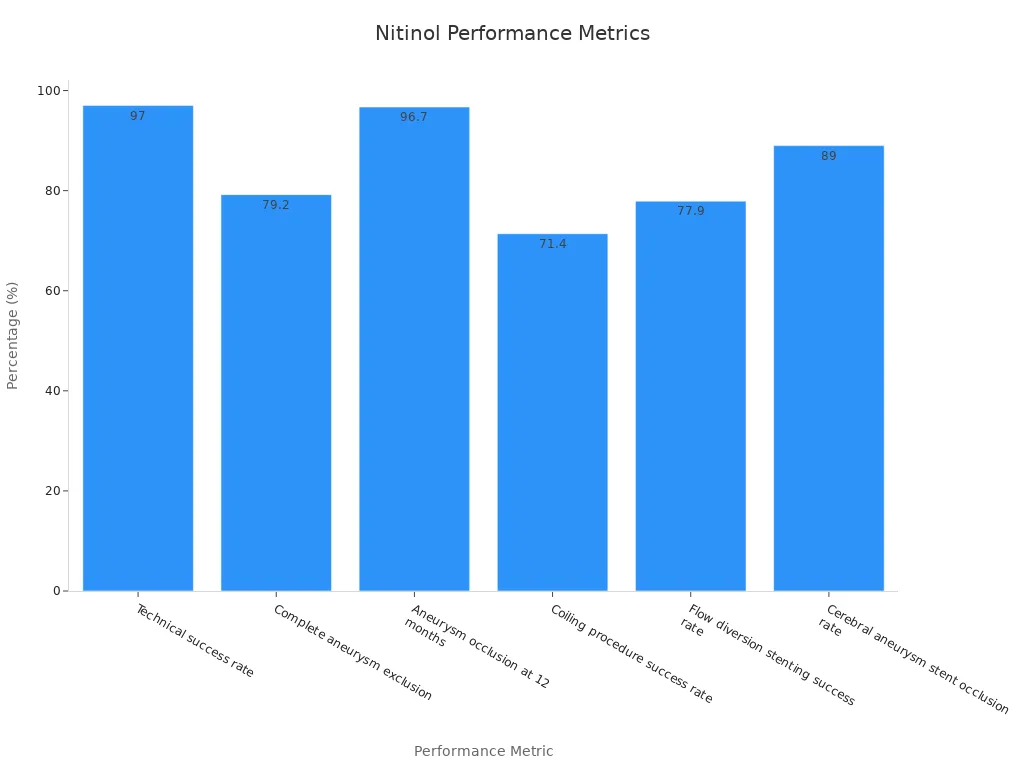

You need tools that move through tiny blood vessels in the brain and body. Tubing lets you design flexible and accurate neurovascular devices. You can use tubing in microcatheters, embolization coils, and flow diverters. These tools must bend without kinking and return to their shape.

Tubing gives you high success rates. In one study, 97% of patients had a good procedure. Complete aneurysm exclusion was 79.2%. At 12 months, aneurysm occlusion was 96.7%. Flow diversion stenting had a 77.9% success rate. Cerebral aneurysm stent occlusion was 89% within 18 months.

Performance Metric | Result |

|---|---|

Technical success rate | 97% (70 of 72 patients) |

Complete aneurysm exclusion | 79.2% (57 of 72 patients) |

Aneurysm occlusion at 12 months | 96.7% (29 of 30 patients) |

Coiling procedure success rate | 71.4% |

Flow diversion stenting success rate | 77.9% |

Cerebral aneurysm stent occlusion rate | 89% within 18 months |

Tubing with superelasticity and shape memory lets your tools move with the body. You lower problems and help the device stay in place. You help more patients with fewer risks.

Orthopedic & Emerging Uses

You want your tools to keep up with new ideas. Tubing is now used in orthopedic devices and other new medical tools. You can use tubing in bone staples, spinal implants, and flexible fixation systems. Tubing helps you make smaller tools that heal faster and last longer.

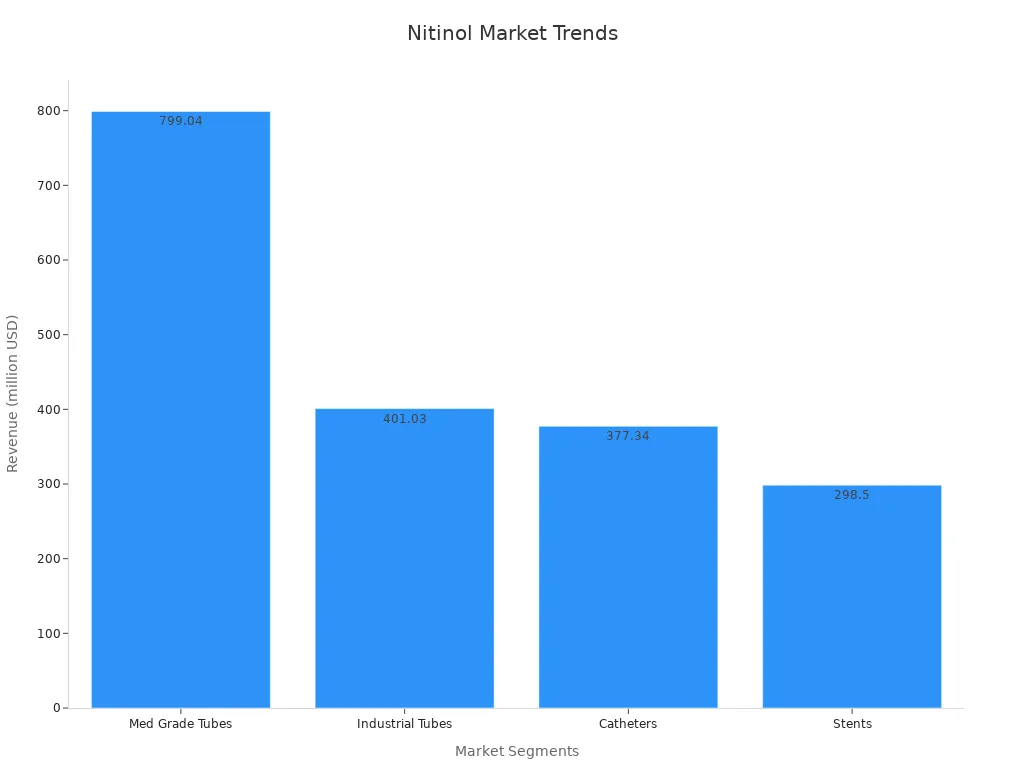

Market data shows tubing leads with a 66.58% share in medical-grade nitinol tubes. The market grows at a 10.68% rate. Catheters, used in orthopedic surgeries, grow at 10.99%. Outpatient surgeries are rising, and more insurance covers nitinol-based tools. AI imaging and robotics help make your tools more accurate and successful.

Market Segment | Market Share / Value (2023) | CAGR (Forecast Period) | Relevance to Orthopedic Devices |

|---|---|---|---|

Medical Grade Nitinol Tubes | 66.58% share, USD 799.04 million | 10.68% | Medical-grade tubes are key for orthopedic implants. |

Catheters | 31.44% share, USD 377.34 million | 10.99% | Catheters are used in less invasive orthopedic surgeries. |

You can be a leader by picking tubing for your orthopedic and new medical tools. You get better results, faster healing, and more choices for your patients.

Tubing stands out in many uses of nitinol tubing. You can trust tubing to give top results in all your medical tools and projects.

Custom extruded nitinol tubing helps keep every device safe and high quality. You get better safety from the start of design to when patients use it. High safety rules mean you lower risks and help patients stay safe. Certifications like ISO 13485 show the tubing is safe and good quality. This means there are fewer recalls and problems. You also get tubing made with exact sizes, proven safety, and strong results in real life. The table below shows why nitinol tubing is a smart choice for your next project:

Metric | Nitinol Tubing Advantage |

|---|---|

Safety | 30% fewer implant rejections |

Quality | 78% fewer recalls with certifications |

Certifications | ISO 13485, FDA approved |

Pick custom extruded nitinol tubing to make your device safer, better quality, and sure to meet all needed certifications.

FAQ

What makes custom extruded nitinol tubing better than standard tubing?

Custom tubing is made for your device. You get the right size and shape. This helps your device work well. It fits each patient better. You lower risks and help more people.

Can you use nitinol tubing in devices for children?

Yes, you can use it for kids. Nitinol tubing comes in small sizes. You can pick what each child needs. This helps young patients heal faster and safer.

How does nitinol tubing help with FDA approval?

Certified nitinol tubing meets FDA rules. Suppliers test every batch for safety. This helps you get approval faster. You avoid delays and problems.

Is custom nitinol tubing expensive?

You save money in the long run. Custom tubing means fewer device failures. You need fewer replacements. Patients do better, so your money is well spent.

How fast can you get custom nitinol tubing?

You can get tubing quickly from good suppliers. Many offer fast samples and delivery. You can launch your device sooner and beat others to market.

See Also

The Importance Of Nitinol Tubing In Modern Medicine

Ways Nitinol Tubing Is Transforming Medical Device Innovation

The Process Behind Manufacturing Nitinol Tubing For Healthcare

A Deep Dive Into Nitinol Tubing Uses In Medical Devices

Nitinol Tubing’s Contribution To Progress In Medical Technology