Complete Guide to Custom Diameter Nitinol Tubing for Medical Use

Nitinol tubing is very important for medical tools because of its special features. It can remember its shape and bend without breaking, which makes it great for strong and precise devices. Custom diameter Nitinol tubing works better by changing size, surface, and use to fit needs. For example, custom designs help liquids move smoothly in systems like liquid tests, making them more accurate and dependable. Nitinol lasts a long time and doesn’t rust, which is why it’s used a lot in heart and brain medical tools.

Key Takeaways

Nitinol tubing is special because it bends and keeps its shape. This makes it great for medical tools like stents and catheters.

Changing the size and thickness of nitinol tubing makes it work better. It helps create accurate and dependable medical tools.

Surface treatments, like electropolishing, make it safer. They stop rust and lower the chance of blood clots in the body.

Nitinol tubing follows strict safety rules. This ensures it is safe and works well inside the body for a long time.

Custom nitinol tubing can cut costs and waste. This makes it a smart and eco-friendly choice for modern medical tools.

Unique Features of Nitinol Tubing

Nitinol tubing is special for medical tools because of its amazing features. These qualities make it a top choice for making safe and effective devices.

Shape Memory and Flexibility

Nitinol can return to its original shape after being bent. This happens when it is heated, a feature called shape memory. It helps nitinol tubing work well in medical tools like stents or catheters. Another feature, superelasticity, lets it bend and stretch a lot without breaking. This makes it perfect for moving through tricky body pathways.

Shape memory works because of changes in its crystal structure.

Careful design is needed to make tubing perform its best.

Level | Details |

|---|---|

1 | Ways to measure how implants change shape and check accuracy. |

2 | Using data from different sources to study wear and tear. |

3 | Predicting how nitinol will behave under stress using data. |

Safe for the Body and Rust-Resistant

Nitinol is safe for the body and doesn’t rust easily. Its surface can be treated to stop nickel from leaking, keeping patients safe. For example, electropolishing adds a smooth layer that prevents rust and reduces protein sticking. These qualities make it great for implants that stay in the body for a long time.

Electropolished nitinol releases less nickel, making it safer.

Surface treatments help stop rust, making devices last longer.

Better blood compatibility lowers the chance of blood clots forming.

Study Details | Results | Source |

|---|---|---|

Electropolishing made a thinner layer, reducing nickel release and rust. | Thinner layer improved safety and stopped rusting. | Sullivan et al. |

Lab tests showed less protein sticking to polished surfaces. | Better blood compatibility due to smoother surface. | Clarke et al. |

Polished nitinol caused fewer blood clots than untreated nitinol. | Safer for use in the body with surface changes. | Previous studies |

Strong and Flexible

Nitinol tubing is tough and bends easily without breaking. This makes it great for tools used in small, delicate surgeries. It can handle repeated use without wearing out.

Nitinol stays strong even when bent a lot.

Its flexibility is key for surgeries like opening blocked arteries.

It lasts through many uses, staying reliable.

These features make nitinol tubing a key part of modern medical tools, offering great performance and safety.

Customization Choices for Nitinol Tubing in Medical Devices

Customizing nitinol tubing is key for safe and effective medical tools. It lets you change its size, surface, and features to fit specific needs. These changes include adjusting the tube's diameter, wall thickness, and coatings.

Adjusting Diameter and Wall Thickness

Changing the diameter and wall thickness makes nitinol tubing more precise. This helps create tools like stents and catheters that are both strong and flexible. These tools need to move through the body without breaking or bending too much.

Smaller diameters and thinner walls are now more popular. They allow for tiny devices used in less invasive surgeries. Thin walls make tubing bend easier, which is helpful in narrow spaces like blood vessels. But the outer size and wall thickness must stay balanced for strength.

Engineers study how to keep this balance during production. Careful control stops problems and ensures good quality.

Tests show how size and thickness changes affect tubing's durability. This helps pick the best design for each use.

For brain stents, exact diameter adjustments are very important. The tubing must bend easily to move through brain blood vessels. This precision lowers risks and helps during surgeries.

Surface Coatings and Finishes

Special coatings and finishes improve nitinol tubing for medical use. They make it safer for the body, reduce blood clots, and last longer. For instance, hydrophilic coatings make the surface smooth and slippery. This reduces friction, making procedures easier and safer.

Hydrogel coatings are another option. They stop things from sticking to the tubing and lower the chance of blood clots. Studies show hydrogel-coated tubing works well even with fast-moving blood. These coatings also make the tubing safe for long-term use.

To ensure quality, manufacturers use strict checks, such as:

Quality Check Step | What It Does |

|---|---|

Laser Tools | Measures tubing size very accurately. |

Sound Wave Testing | Finds cracks or flaws without harming the tubing. |

Size Checks | Confirms thickness, roundness, and outer size. |

Strength Tests | Tests bending ability and overall durability. |

Surface Finishing | Improves rust resistance and performance. |

These steps make sure the tubing meets high medical standards.

Special Features for Medical Tools

Nitinol tubing can be made with extra features for special uses. For example, it can "remember" shapes and return to them when heated. This is useful for stents that need to expand and stay in place.

New improvements have made medical tools even better. Nitinol stents help prevent artery narrowing by moving with blood vessels. Flexible surgical tools also benefit from nitinol, making them easier to guide in the body.

Studies show nitinol is safe for long-term use in the body. Surface treatments make it even safer, so it works well for implants. These upgrades make nitinol tubing perfect for modern medical needs.

Benefits of Custom Diameter Nitinol Tubing

Custom nitinol tubing has many benefits for medical tools. Its special features and exact designs improve how devices work, meet safety rules, and save money.

Better Performance in Medical Tools

Custom nitinol tubing helps medical tools work better. Changing its size and features makes it fit specific needs. This ensures tools like stents and catheters work well in surgeries. Nitinol's ability to bend and return to its shape helps it move with the body. This makes it safe and effective during medical procedures.

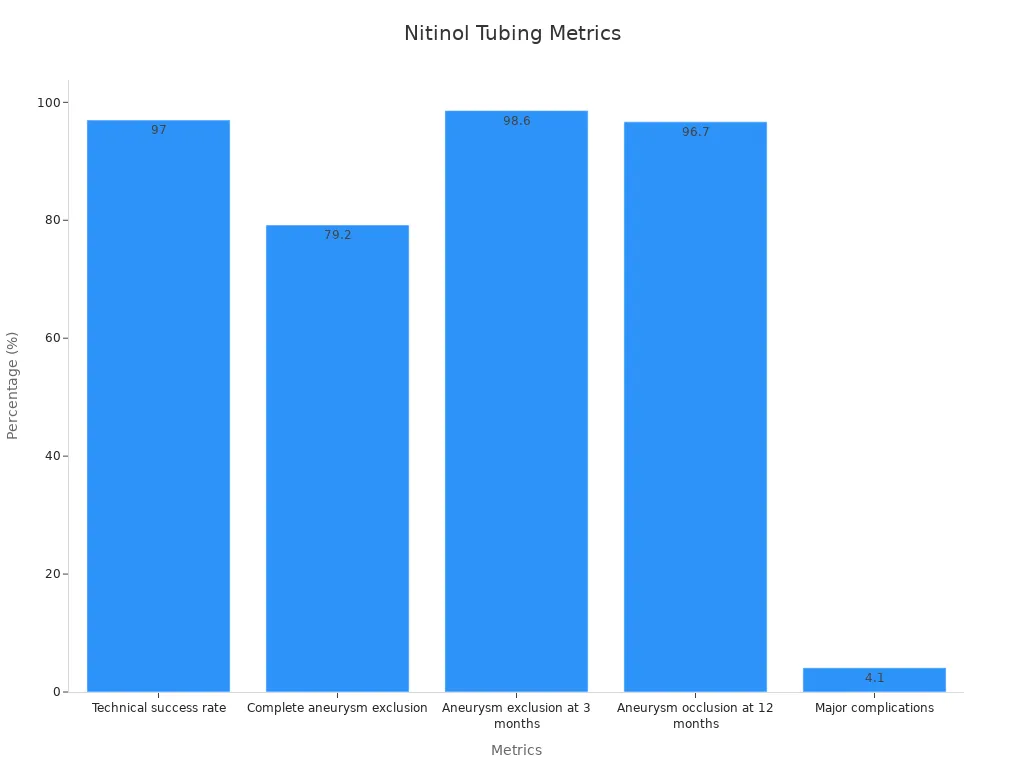

Metric | Result |

|---|---|

Technical success rate | |

Complete aneurysm exclusion | 79.2% (57 of 72 patients) |

Aneurysm exclusion at 3 months | 98.6% (70 of 71 patients) |

Aneurysm occlusion at 12 months | 96.7% (29 of 30 patients) |

Major complications | 4.1% (3 patients) |

These numbers show how custom nitinol tubing makes medical tools more dependable and useful.

Meets Safety Rules

Custom nitinol tubing follows strict safety rules for medical tools. Makers follow standards like ASTM F2063, which checks nitinol's strength and safety. These rules make sure the tubing works well under pressure and stays safe.

Compliance Standard | Description |

|---|---|

ASTM F2063 | Sets rules for nitinol used in medical tools. |

Testing Procedures | Includes tests for strength and heat changes. |

Specifications | Lists rules for material makeup and durability. |

By following these rules, custom nitinol tubing stays safe and reliable for medical use.

Saves Money and Cuts Waste

Custom nitinol tubing helps save money and reduce waste. It lasts a long time, so tools don’t need replacing often. New ways to make it use less material, which helps the environment.

Key Points | Description |

|---|---|

Improves quality while lowering costs. | |

Waste Reduction | Better production methods cut down on waste. |

Market Demand | More demand for precise tools boosts its use. |

These benefits make custom nitinol tubing a smart choice for medical tools. It balances good performance, safety, and saving resources.

Uses of Custom Nitinol Tubing in Medical Tools

Custom nitinol tubing is important for improving medical tools. Its special abilities, like shape memory and flexibility, make it useful in heart, brain, and other medical areas.

Heart Tools

Nitinol tubing has changed how heart problems are treated. It can expand and return to its shape, making it reliable. For example, nitinol stents move with blood vessels, lowering risks. Studies like the MISAGO 1 trial showed nitinol stents work better than older methods. The ORION trial also proved nitinol stents keep blood vessels open and flexible.

Feature | Nitinol Tools | Older Materials |

|---|---|---|

Healing Improvement | Not Available | |

Pain Reduction | Faster healing | Not Available |

Risk of Problems | Lower | Higher |

Nitinol tubing is safer because it doesn’t rust and works well with the body. This makes it great for long-term heart treatments.

Brain Tools

Brain stents and tools need nitinol tubing for its strength and bendability. These tools must move through tiny, tricky brain pathways. Nitinol’s flexibility and shape memory help stents fit blood vessels without breaking.

Studies show nitinol works well in brain surgeries. For example, nitinol guide wires lower surgery problems by 25% compared to steel ones. They are easier to control and bend, making them perfect for small surgeries. Nitinol is also safe for the body, so it’s a top choice for brain tools.

Other Medical Uses

Nitinol tubing is used in many other medical tools. Its strength and flexibility make it great for small surgery tools like biopsy forceps. In bone surgeries, nitinol implants adjust to body movements. It also improves catheters and guide wires for tests and treatments.

Custom nitinol tubing is made to fit each tool’s needs. Its mix of strength, flexibility, and safety makes it a key part of modern medical tools.

Picking the Best Custom Nitinol Tubing

Choosing nitinol tubing for medical tools needs careful planning. You must think about your needs, the material's features, and work with experts. Each step helps make sure the tubing works well in devices.

Knowing What Your Device Needs

The first step is to understand what your device requires. Different tools need specific features like flexibility or strength. For example, guidewires for heart procedures must bend without harming blood vessels. Stents need to spring back into shape to work properly inside the body.

You should check how the tubing performs based on your needs. Important things to look at include:

Feature | What It Means |

|---|---|

Fatigue Life | Shows how long the tubing lasts under repeated use. |

Tensile Strength | Measures how much weight it can handle before breaking. |

Residual Stretch | Tests how the tubing behaves when stretched in tough conditions. |

Smaller tubing is better for tight spaces in the body. Wall thickness and surface finish also affect how strong and reliable the tubing is. Matching these details to your tool’s needs ensures it works well.

Checking Material Features

Nitinol’s special features make it great for medical tools. It bends and moves easily, which helps in tricky surgeries. It’s safe for the body and doesn’t cause bad reactions. It also resists rust, so it lasts longer inside the body.

Tests help check nitinol’s strength and flexibility. These include:

Property | Value |

|---|---|

Maximum Strength | 1241 MPa to 1378 MPa |

Stretch Before Breaking | Over 10% |

Upper Stress Limit | Over 552 MPa |

Lower Stress Limit | Over 207 MPa |

Active Phase Range | 50°F to 64°F |

Permanent Change | Less than 0.5% after stretching 8% |

These numbers follow ASTM F2063 rules, which ensure safety. Comparing nitinol to other materials like steel shows its unique benefits, like shape memory and flexibility.

Teaming Up with Experts

Working with manufacturers is key to getting the right tubing. They can adjust the size, thickness, and surface to fit your needs. They also make sure the tubing meets medical safety rules.

Good teamwork means sharing clear details about your device. Engineers can tweak the design to improve performance. For instance, slippery coatings reduce friction, and polishing stops rust.

Manufacturers also run strict tests, like laser checks and strength tests. These steps ensure the tubing is safe and high-quality. By working with skilled makers, you get tubing that’s reliable and works perfectly.

Future Trends in Custom Nitinol Tubing

Advances in Manufacturing Techniques

New ways to make nitinol tubing are changing medical tools. 3D printing helps create detailed designs faster and more efficiently. This method allows for unique shapes made for specific medical needs. Special surface treatments, like electropolishing, make the tubing resist rust and work better with the body. These treatments also help tools last longer. Precision engineering is another important method. It lets manufacturers adjust tubing to fit each patient’s needs, improving how well it works in medical devices.

🚀 Tip: Using these new methods keeps nitinol tubing innovative and effective for medical tools.

Integration with Emerging Medical Technologies

Custom nitinol tubing is now used with advanced medical technologies. For example, laser-cut stents show how oxide layers affect rust resistance. This proves how important accurate manufacturing is. Companies like Lumenous Device Technologies Inc. have created solutions like Everglide Laser Cut. These improve catheter performance and allow for new designs in nitinol tubing. These innovations make medical tools more reliable and better for complex procedures.

💡 Note: New ideas like these help nitinol tubing meet modern medical needs.

Sustainability in Nitinol Tubing Production

Making nitinol tubing is becoming more eco-friendly. Manufacturers use new technology to save energy and cut down on pollution. Recycling systems now recover and reuse materials, reducing the need for new resources. Waste reduction plans ensure materials are used wisely during production. Life Cycle Assessments (LCA) check the environmental impact of nitinol from start to finish.

Description | |

|---|---|

Waste Reduction | Less material waste during production for smarter resource use. |

Energy Efficiency | New methods save energy and lower pollution. |

Closed-Loop Recycling | Reusing materials reduces the need for new raw inputs. |

Life Cycle Assessment (LCA) | Measures the full environmental impact of nitinol products. |

These green efforts make sure nitinol tubing stays high-quality while helping the environment.

Nitinol tubing is crucial for improving medical tools. Its special traits, like being safe for the body, resisting rust, staying strong under stress, and remembering shapes, make it reliable and adaptable. These features are why it’s used in devices like stents and catheters.

Property | Importance |

|---|---|

Biocompatibility | Safe for the body, lowering risks of swelling or irritation. |

Corrosion Resistance | Stays reliable over time and avoids harmful reactions. |

Fatigue Strength | Stays strong under repeated use, making devices last longer. |

Shape Memory Behavior | Adjusts to blood vessels, improving safety and how well it works. |

Customizing nitinol tubing improves how it works by matching it to specific needs. Changing its size, adding coatings, or tweaking features ensures tools are precise and dependable. Working with skilled manufacturers helps create tubing that fits your exact needs and works perfectly in medical tools.

💡 Tip: Teaming up with experts ensures your nitinol tubing is both effective and meets safety rules.

FAQ

Why is nitinol tubing special for medical tools?

Nitinol tubing can bend and return to its shape. It moves with the body and doesn’t rust, making it safe for long-term use.

How does changing nitinol tubing help?

Changing its size, thickness, and surface makes it fit better. This improves how tools work and keeps patients safer during procedures.

Is nitinol tubing safe for people?

Yes, nitinol is safe and doesn’t rust. Special coatings stop nickel from leaking, making it good for implants and other uses.

Can nitinol tubing be used in small surgeries?

Yes, it’s great for small surgeries. It bends easily and stays strong, helping it move through tight spaces like blood vessels.

How do makers check nitinol tubing quality?

Makers use tools like lasers and strength tests. They also polish the surface to make sure it’s safe and works well.

See Also

The Manufacturing Process of Nitinol Tubing for Medicine

The Importance of Nitinol Tubing in Modern Medicine

Nitinol Tubing Uses in Innovative Healthcare Technologies

Nitinol Tubing's Impact on the Future of Medical Devices

Nitinol Tubing's Contribution to Progress in Medical Technology