What Is the Current Price per Meter of NiTi Tubing

You can expect the average price per meter of NiTi tubing to be between $80 and $250. This is based on recent supplier data. Prices can change depending on where you buy it. The amount you order also affects the price. The product features matter too. When you check the NiTi tubing price per meter, you may see different prices. Always look at the price per meter. Compare the details before you decide.

Key Takeaways

NiTi tubing costs between $80 and $250 for each meter. The price changes depending on who sells it, how much you buy, and what features it has.

Always look at prices from many sellers. Make sure you know if the price is for each meter, each kilogram, or each piece. This helps you not get confused.

Buying a lot at once can make each meter cheaper. Many sellers give discounts if you order more.

Think about the material grade and size. If the tubing is more pure or has thicker walls, it will cost more. So, check what you need before you buy.

Look for quality certifications like ASTM F2063 and FDA standards. These show the tubing is safe and meets the right rules.

NiTi Tubing Price per Meter

Current Price Range

If you search for NiTi tubing price per meter, you will see many prices. Some suppliers sell it for $9 per meter. Others charge more than $150 per meter. You should check each offer carefully. The price changes with the supplier. It also depends on how much you buy. The type of tubing you want matters too.

Here is a table with prices from top suppliers:

Supplier | Price Range (per meter) |

|---|---|

Shaanxi Innovmet Co., Ltd. | $96 - $115 |

Jiangsu Tisco Industrial Co., Ltd. | Converted from $8 - $12/kg (specific per meter not provided) |

Shaanxi Innovmet gives a clear price per meter. Jiangsu Tisco shows prices per kilogram. You need to ask them for a quote to know the price per meter. Some suppliers use different units. Always check if the price is per meter, per kilogram, or per piece.

Most NiTi tubing prices per meter are between $40 and $150. Lower prices often mean you must buy a lot. Higher prices may have special features or be medical-grade. You should compare prices for each supplier before you buy.

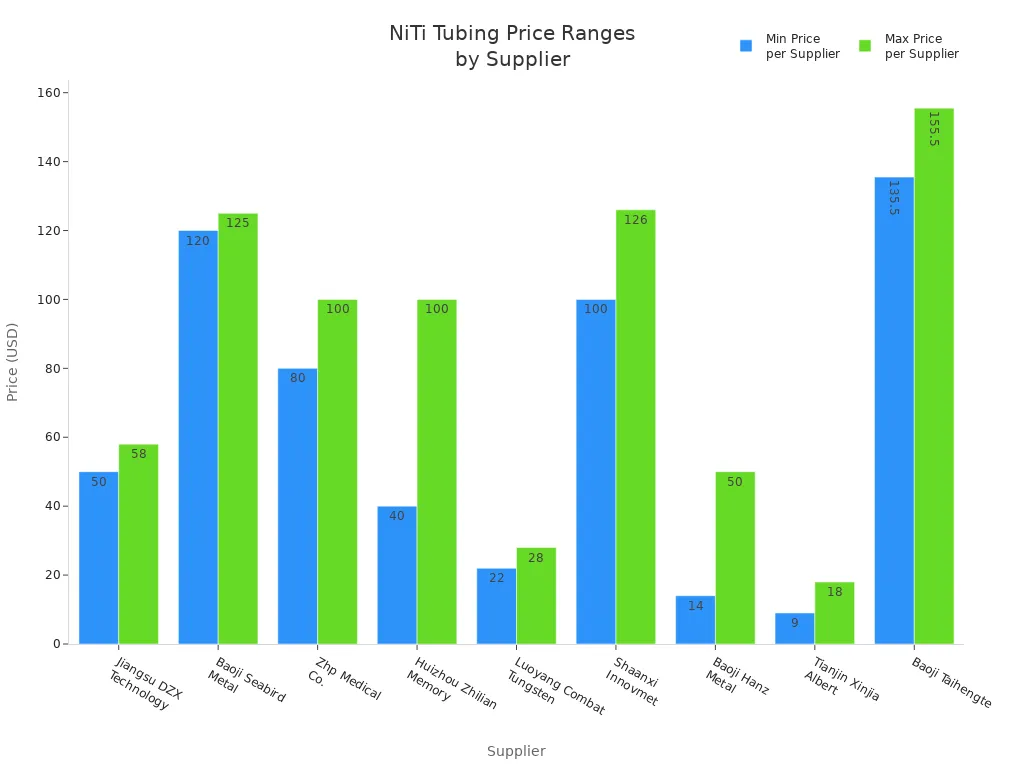

Supplier Price Comparison

Many suppliers have different prices and order rules. Some companies give discounts if you buy a lot. Others sell high precision or medical-grade tubing. The table below shows how prices and order sizes are different:

Supplier | Price Range (USD) | Minimum Order Quantity | Key Attributes |

|---|---|---|---|

Jiangsu DZX Technology Co.,Ltd | $50 - $58 | 1 meter | Very low MOQ, volume discounts |

Baoji Seabird Metal | $120 - $125 | 1 piece | High precision, top review score |

Zhp Medical Co. | $80 - $100 | 1 meter | Competitive pricing for volume |

Huizhou Zhilian Memory | $40 - $100 | 10 meters | Significant volume discounts |

Luoyang Combat Tungsten & Molybdenum | $22 - $28 | 50 kg | Very low bulk price per kg |

Shaanxi Innovmet | $100 - $126 | 10 meters | Focus on medical grade |

Baoji Hanz Metal | $14 - $50 | 3 pieces | Very low price per piece at high volumes |

Tianjin Xinjia Albert | $9 - $18 | 10 tons | Extremely low bulk price per ton |

Baoji Taihengte | $135.50 - $155.50 | 1 kilogram | Customization focus |

Look at the minimum order quantity when you compare suppliers. Some let you buy just one meter. Others want you to buy in bulk. Bulk orders can lower the price per meter. If you want high precision or medical-grade tubing, you will pay more.

Tip: Always ask for a full quote. Check if the price covers shipping, customization, or special certifications.

The price per meter changes with product details. High-purity materials, hard manufacturing, and strict checks can make the price go up. Tubing for medical use costs more. If you buy wire or sheet, it may cost less. The form of nitinol, titanium cost, and how it is made all change the price.

You can find the best price by comparing suppliers. Check order sizes and product features. Know what you need before you buy.

Price Factors

Material Grade

NiTi tubing prices change with the material grade. High-purity grades cost more money. Medical-grade tubing is the most expensive. It needs strict checks for quality. If you want tubing for medical or high-tech use, expect higher prices. Lower grades are fine for general use and cost less. Always look at the grade before you buy.

Dimensions & Wall Thickness

The tubing size affects the price. Thicker walls use more material, so they cost more. Longer or wider tubes also cost more money. Seamless nitinol tubes with tight tolerances cost extra. Measure what you need before you order. This helps you avoid paying for extra material.

Customization Options

Custom features make the price go up. You might want special shapes or finishes. Extra testing can also raise the price. Some suppliers can make nitinol tubing for special projects. Custom sizes or coatings cost more. Standard tubing is cheaper and faster to get.

Order Quantity

How much you buy changes the price. Buying in bulk gives you a lower price per meter. Many suppliers give discounts for big orders. You can see this in the table below:

Pricing Strategy | Description |

|---|---|

Competitive Pricing | Gives you good value and quality. |

Bulk Discounts | You save money when you buy a lot. |

If you buy only a little, you pay more per meter. Large orders help you save money if you need a lot of tubing.

Tip: Always ask suppliers about discounts for bigger orders. This helps you get the best deal.

Comparing Suppliers

Evaluating Quotes

When you look at quotes from NiTi tubing suppliers, check more than just price. Each quote can have different things included. Some suppliers give prices per meter. Others use kilograms or pieces. You need to see what the price covers. Ask if shipping, testing, or extra fees are included.

Here is a table to show what matters most when you look at quotes:

Important Factors for Buying | Why They Matter |

|---|---|

Temperature (Af) | Makes sure it works for your project |

Size | Helps it fit and work right |

Surface Smoothness | Keeps it safe and stops rust |

Certifications | Shows it is high quality and follows rules |

Best Buying Tips | Testing makes sure it is safe and works well |

Tip: Always ask for a sample or test report before you buy. This helps you know the tubing will work for your needs.

Quality & Certification

Check the quality and certifications before you buy NiTi tubing. High-purity nitinol is needed for medical and airplane uses. If there are impurities, the tubing can be unsafe. Suppliers use special cleaning to meet strict rules. This makes the price higher, but you get better tubing.

Some common certifications are ASTM F2063 and FDA standards. These show the tubing is safe, does not rust, and bends well. Medical-grade tubing must follow even tougher rules. If you need tubing for medical use, look for these certifications.

ASTM F2063 means it does not rust and is safe for the body.

FDA standards show it is safe for medical use.

Very pure nitinol costs more but works better.

Shipping & Lead Time

Shipping and delivery times can change your choice. Some suppliers, like Confluent Medical, can make NiTi tubing in 4-6 weeks. This is faster than before and helps you plan.

Shipping costs can have many extra fees. You might pay for the Panama or Suez Canal, low sulfur fuel, or even for piracy risk. Taxes and duties also add to the price. Delays can happen, and you may pay more if your shipment is stuck at a port.

Charge Type | Description |

|---|---|

PCC | Panama Canal fee |

SUE | Suez Canal surcharge |

LSC | Low sulfur fuel charge |

Delay Fees | Extra costs for late shipments |

Demurrage | Storage fees at ports |

Detention | Fees for slow loading or unloading |

Taxes and Duties | Costs based on product value |

Note: Ask your supplier for a full list of shipping costs and delivery times. This helps you avoid surprises and plan your budget.

Market Trends

Raw Material Costs

It is important to watch raw material prices. Nickel and titanium are used to make NiTi tubing. Their prices change a lot. If nickel costs more, tubing costs more too. Titanium prices also change the final price. Suppliers change their prices when materials cost more.

Some companies buy lots of materials to save money. Others use recycled metals to lower costs. You can ask your supplier how they get their materials. If prices go up fast, it is usually because raw materials cost more. Check news for nickel and titanium price updates.

Tip: If you have a big project, order when raw material prices are low. This can help you save money later.

Demand & Technology

More people want NiTi tubing now. Hospitals and clinics use these tubes for medical devices. New technology makes tubing safer and easier to bend. Many companies offer tubing with better shape memory and rust protection.

Regional market conditions change prices too:

North America will have 43.1% of the market in 2025. This is because of new safe materials and more people with health problems.

Healthcare workers in North America need strong tubing for treatment and tests.

Strict rules in North America make companies build better tubing.

Asia Pacific needs more tubing because healthcare is improving and more people are sick.

Local companies in Asia Pacific make good tubing for less money.

Look for suppliers who use new technology. Tubing with advanced features costs more but works better. If you want to save money, compare tubing from different places. Some regions have lower prices because they use new ways to make tubing.

Note: Technology and demand change fast. Check for new updates before you buy NiTi tubing.

NiTi tubing usually costs from $80 to $250 for each meter. The price changes with material grade, size, and custom options. How much you buy also changes the price. You should always compare different suppliers. Check for the newest prices before you buy. Prices can go up or down often. You want to get the best deal for your project. If you only look at price, you might get bad quality. You could also have extra costs, like welding issues or waiting longer. Make sure to check both price and quality before buying.

FAQ

What are the main uses for NiTi tubing?

NiTi tubing is used in many medical tools. Doctors use it for stents and catheters. It is also used for surgical tools. Engineers use NiTi tubing in robots and sensors. These devices need tubing that is strong and bends easily. The tubing can go back to its original shape.

How do NiTi tubing prices change for medical devices?

NiTi tubing costs more for medical devices. Stents and catheters need pure tubing. They must pass strict tests. These devices have safety rules. Suppliers charge extra for special features and certifications.

Can you use NiTi tubing for catheters and stents?

NiTi tubing works for catheters and stents. These devices need tubing that bends and returns to shape. NiTi tubing does this well. You should check if the tubing meets medical standards before buying.

What should you check before buying NiTi tubing for devices?

Look at the size and grade of the tubing. Check if it has the right certifications. Make sure it fits your device, like a catheter or stent. Ask for test reports from the supplier. See if they ship quickly. You want tubing that works well in your device.

Why do some devices need custom NiTi tubing?

Some devices need special shapes or sizes. Catheters and stents may need custom tubing. Custom tubing helps these devices work better. You can ask for special finishes or coatings. Custom tubing costs more but helps your device perform well.

See Also

Finding The Most Cost-Effective Nitinol Tubing Supplier

The Manufacturing Process Of Nitinol Tubing For Medicine

Choosing The Right Nitinol Tubing Supplier For You