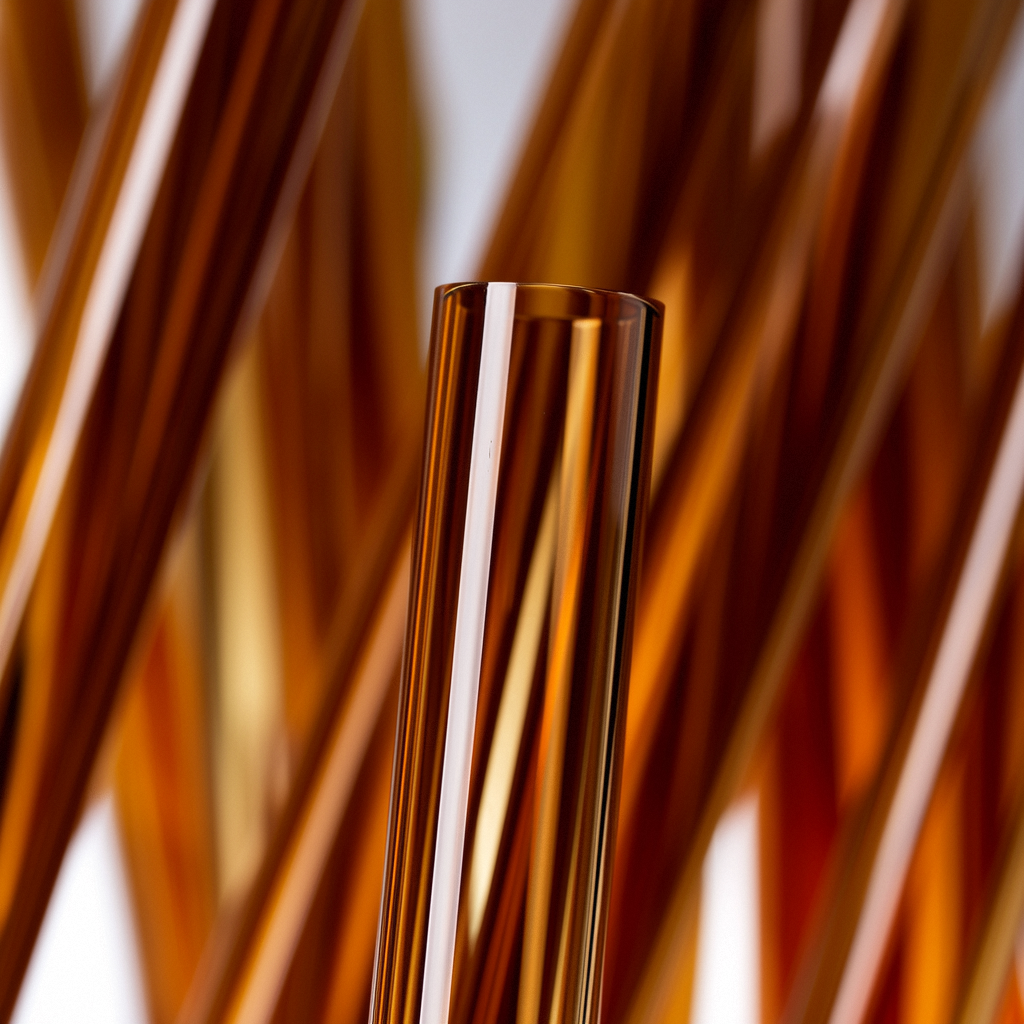

Comparing Customizable Polyimide Tubing for Medical and Industrial Applications

Customizable polyimide tubing is very important in medical and industrial uses. This is because it can handle high heat, resist chemicals, and bend easily. It is often used in tools that need to be strong and precise.

The worldwide need for customizable polyimide tubing shows how valuable it is:

In 2023, the market was worth $1.2 billion. By 2032, it may grow to $2.3 billion, with a yearly growth rate of 7.2%.

Tubing with an inner size smaller than 0.1 mm is growing fast.

The medical field keeps using more tubing as healthcare improves.

This blog talks about how customizable polyimide tubing can be tailored to meet special needs in these areas and guides your choices.

Key Takeaways

Custom polyimide tubing is important for medical and industrial uses.

It is strong against heat, chemicals, and can bend easily.

Picking the right tubing means knowing what you need it for.

Medical tubing must be safe, while industrial tubing needs strength.

Custom designs make tubing work better and last longer.

These changes help the tubing fit different jobs perfectly.

Overview of Customizable Polyimide Tubing

What It Is and Its Main Features

Customizable polyimide tubing is a special kind of tube. It is made from polyimide, a strong and high-quality material. This tubing is known for handling heat, resisting chemicals, and being very strong. It can be adjusted to fit different needs, making it useful in both medical and industrial areas.

One great thing about polyimide tubing is how it works in tough conditions. It can handle high heat without breaking or changing shape. It also lasts a long time, even in hard environments. Its thin and light design makes it perfect for jobs needing accuracy and flexibility.

Why It’s Useful in Medicine and Industry

Polyimide tubing is helpful in many medical and industrial jobs. In medicine, it is used in catheters, guidewires, and insulated wires. For example, its small size and strength make it great for catheters used in veins or the bladder. It also keeps electricity safe in medical tools.

In factories, this tubing is strong against scratches and chemicals. It can handle acids, oils, and cleaning liquids, so it works well in rough places. It also stays strong in hot temperatures. New ideas like PI tube make it smoother, so it works better in machines.

Use | Why It’s Helpful |

|---|---|

Catheters | Works well for vein and bladder catheters, small but strong. |

Insulated Wire | Keeps electricity safe and resists scratches, improving wires. |

Guidewires | Thin tubing helps guidewires move easily and stay strong. |

Scratch Resistance | Very tough, lasts long like PEEK material. |

Chemical Resistance | Handles acids, oils, and cleaners, useful in many places. |

Heat Resistance | Works well in hot places, good for many tasks. |

Whether for delicate medical tools or tough factory jobs, polyimide tubing works amazingly well.

Key Features of Customizable Polyimide Tubing

Customization Options

Polyimide tubing can be customized in many ways. You can pick different materials, sizes, or colors to match your needs. Special shapes or stronger designs can also be created for extra strength. In medicine, stronger tubing helps in procedures like ureteroscopy and endovascular surgeries.

Customization Option | Example Use |

|---|---|

Materials, Sizes, Colors | Tubing made for specific jobs |

Special Shapes | Unique designs for special tools |

Stronger Designs | Tougher tubing for medical use |

Performance Impact of Customization

Changing the tubing improves how it works. Picking the right material or adding strength makes it better for tough jobs. Stronger tubing lasts under high pressure, while smooth coatings make it slide easily. In medicine, custom tubing makes catheters and guidewires safer and more accurate. In factories, it resists chemicals and heat, working well for a long time. Custom designs make the tubing work better and last longer, so you don’t need to replace it often.

Flexibility and Durability in Applications

Polyimide tubing is both bendable and strong. It bends without breaking, which is great for tight spaces like blood vessels or machines. It also stays strong in tough conditions. Medical tubing moves through delicate areas but stays sturdy. In factories, it handles chemicals, heat, and stress without wearing out. This mix of flexibility and strength makes it work well in surgeries or manufacturing.

Medical vs. Industrial Applications

Medical Applications and Requirements

Polyimide tubing is very important in medicine. It is safe to use inside the body. Doctors use it in catheters, guidewires, and surgery tools. These tools need to be precise and bendable. The tubing can handle cleaning methods like heat or chemicals. This makes it good for using again and again. For example, in small surgeries, its thin and strong design helps it move through tiny blood vessels easily.

Medical tubing must follow strict rules. It has to work well under high pressure and heat. It also needs to stay strong and not break. This keeps patients safe and helps surgeries succeed.

Industrial Applications and Requirements

In factories, polyimide tubing is tough and lasts long. It works well in electronics, airplanes, and cars. For example, it insulates wires in flexible circuits. In airplanes, it is light and handles heat, so it’s used in fuel lines. In cars, it resists heat in fuel and oil systems.

Industrial tubing must survive hard conditions. It faces chemicals, oils, and high heat. It stays strong for a long time, so it doesn’t need to be replaced often. This saves money and improves how machines work.

Application Sector | Key Features | Why It’s Important |

|---|---|---|

Medical Devices | Safe for the body, reusable | Needed for catheters and surgery tools |

Electronics | Protects electricity | Used in circuits and wires that face high heat |

Aerospace | Light, handles heat | Good for fuel lines and heat shields |

Automotive | Resists heat | Works in fuel and oil systems |

Key Differences Between Medical and Industrial Uses

Medical and industrial tubing have different needs. Medical tubing must be safe for the body and easy to clean. Industrial tubing needs to resist chemicals and heat. For example, medical tubing must bend for catheters. Industrial tubing needs to be strong to handle stress.

Studies show polyimide tubing is better than silicone, PTFE, and PVC. Silicone isn’t strong or heat-resistant enough for factories. PTFE is tough but not bendable for medical use. PVC gives off harmful chemicals when hot, so it’s not good for either use.

Tubing Type | Main Problems | How It Performs |

|---|---|---|

Silicone | Not strong or heat-resistant. | Breaks under pressure or heat. |

PTFE | Not bendable for medical tools. | Good with chemicals but too stiff for catheters. |

PVC | Releases harmful chemicals when heated. | Weak in strength and chemical resistance. |

Knowing these differences helps you pick the right tubing. This ensures safety and better results for your needs.

Pros and Cons of Customizable Polyimide Tubing

Advantages of Customization

Custom polyimide tubing has many benefits. You can change it to fit specific needs in medicine or factories. Adjusting its size, material, or coating makes it work better. Smooth coatings help it slide easily, which is great for tools like catheters. Stronger materials make it last longer in tough factory conditions.

Customization improves how the tubing works. Picking the right features helps it handle pressure, heat, or chemicals. This makes it useful for surgeries or heavy factory tasks. Its flexibility makes it a smart choice for many jobs.

Limitations in Certain Applications

Polyimide tubing isn’t perfect for everything. Its heat resistance and strength might not be needed for simple tasks. This can make it too fancy and expensive for some uses. Its thin design is helpful but may lack stiffness for certain factory jobs.

Some chemicals can damage the tubing over time. While it resists many substances, highly reactive ones can weaken it. You should check your needs carefully before choosing this tubing.

Cost vs. Performance Considerations

Polyimide tubing costs more because of its high quality. Features like heat resistance and chemical strength make it pricier than PVC or silicone. But it’s worth it for jobs needing reliability and long-lasting materials.

The market for seamless polyimide tubing is growing fast. By 2024, it could be worth millions, with yearly growth of 8-10%. This shows more demand for strong materials in electronics and medicine. Though it costs more upfront, it saves money later by lasting longer and working better.

Choosing the Right Customizable Polyimide Tubing

Key Factors to Consider

When picking polyimide tubing, think about important factors. Tubing must fit your needs. More people want less invasive surgeries, so flexible and precise tubing is key. For example, catheters and endoscopes need tubing that bends in tight spaces but stays strong. Wearable medical devices also need tubing that is light and tough.

Better diagnostic tools also affect tubing choices. Tubing must handle tough conditions and still work well in advanced machines. Customization is now very popular. You can adjust tubing size, coating, or material for special uses. New manufacturing methods make this possible.

The table below shows these factors:

Critical Factor | Explanation |

|---|---|

Advancements in Minimally Invasive Procedures | Tubing is needed for tools like catheters and endoscopes in small surgeries. |

Rising Demand for Medical Devices | Flexible and safe tubing is important for many medical tools. |

Technological Advancements in Diagnostics | Strong tubing is needed for advanced diagnostic machines. |

Integration with Minimally Invasive Devices | Tubing made for new tools helps patients recover faster. |

Customization and Precision Manufacturing | Custom tubing improves how medical tools work. |

Focus on Biocompatibility and Safety | Tubing follows strict safety rules for medical use. |

Expansion in the Wearable Medical Device Market | Durable tubing works well in sensors and health monitors. |

Increasing Demand for Customized Medical Solutions | Custom tubing makes devices work better and helps patients. |

Growth in Global Healthcare Infrastructure | High-quality tubing supports growing healthcare systems worldwide. |

Checklist for Selection

Use this checklist to pick the right tubing:

Know Your Needs: Decide if the tubing is for medical or factory use. Think about safety, flexibility, and strength.

Check Material Strength: Make sure the tubing can handle heat, pressure, and chemicals.

Look for Custom Options: Find tubing you can adjust for size, coating, or strength.

Follow Safety Rules: For medical use, check if the tubing meets safety standards.

Think About Durability: Pick tubing that lasts long and doesn’t need replacing often.

Choose a Good Maker: Work with experts in making high-quality tubing.

By using this checklist, you can find tubing that works best for your needs.

Custom polyimide tubing is very useful for many jobs. It works well in both medical tools and factory machines. Its ability to handle heat and bend makes it great for precise tasks.

Knowing what you need is very important. Whether for small surgeries or tough factory work, picking the right features helps you succeed.

To pick the best tubing:

Know what you need it for.

Check how it can be customized.

Work with reliable makers.

By doing these steps, you can choose wisely and get the best results.

FAQ

Why is polyimide tubing better for medical tools?

Polyimide tubing handles heat, bends easily, and lasts long. It is safe to use with medical materials, making it great for catheters and surgery tools.

Can polyimide tubing work in high-pressure factory jobs?

Yes, it works well under high pressure. Its strength and chemical resistance make it perfect for tough factory tasks, like making medical tubes.

How do you pick the best polyimide tubing?

Think about what you need it for, like bending or strength. For medical use, check if it’s safe for the body and fits advanced tools.