What Is Color Coded PET Heat Shrink Tubing for Medical Wires and Its Key Features

You use color coded PET heat shrink for medical wires. It helps insulate, protect, and identify wires in medical devices. PET material gives strong protection. It also resists heat. Color coding helps you avoid mistakes. Mistakes can cause safety problems. Look at the table below for common risks when wires are mixed up:

Safety Incident Type | Description |

|---|---|

Electrical shocks | Seeing a red electrical wire (hot wire) lowers shock risk. |

Burns | Mixing up wires can cause burns from electrical surges. |

Fires | Using the right colors stops fires from wrong wire connections. |

Using the same color coding helps keep patients safe. It also follows rules from hospital groups.

Key Takeaways

Color coded PET heat shrink tubing covers medical wires. It keeps wires safe from shocks, burns, and fires.

Using the same color system helps people find wires fast. This makes work easier and helps stop mistakes in busy hospitals.

PET material is strong and does not melt easily. It works well for medical use where cleaning and safety matter a lot.

Putting heat shrink tubing on right makes a tight cover. This keeps wires safe from dirt and water. It helps medical devices last longer.

Checking and fixing heat shrink tubing often can stop problems. This keeps medical devices safe and working well.

Color Coded PET Heat Shrink for Medical Wires

What Is Color Coded PET Heat Shrink Tubing

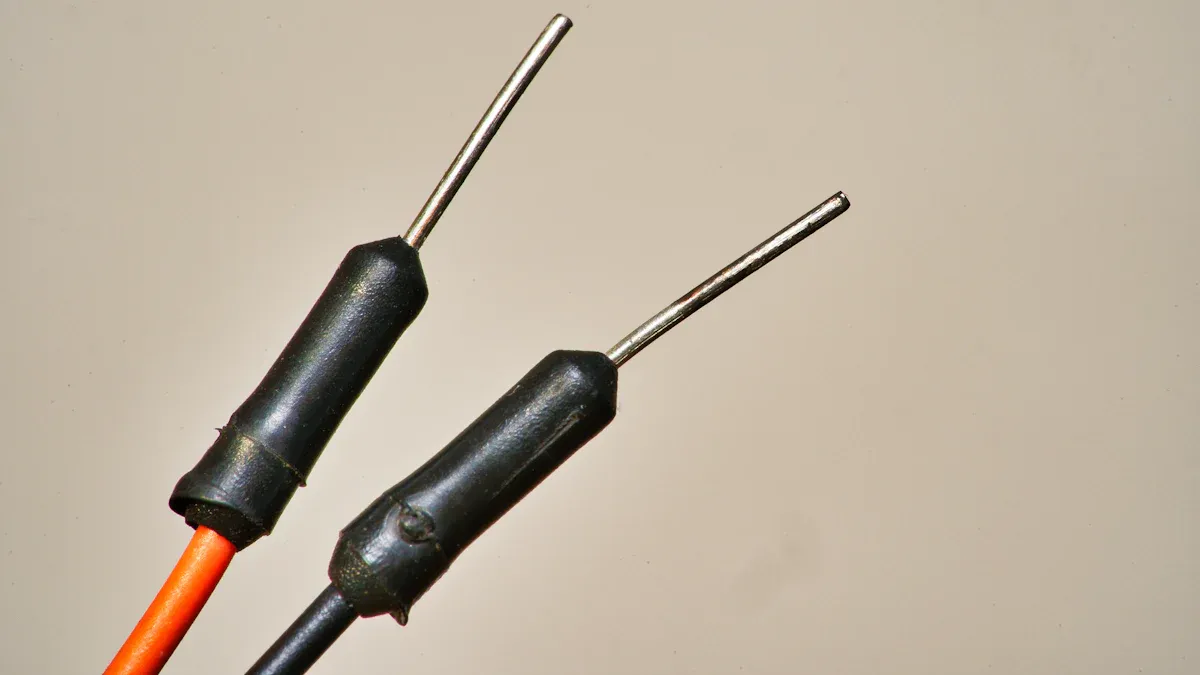

Color coded PET heat shrink covers medical wires. It keeps wires safe and easy to see. The tubing goes over wires in medical devices. When you heat it, the tubing shrinks tight. This gives each wire insulation and protection. The colors help you know each wire’s job. You can find problems fast. You are less likely to mix up wires in busy places.

The tubing comes in different sizes and thicknesses. You can pick the best one for your device. Check the table below for common sizes and shrink ratios:

Specification | Value |

|---|---|

Standard Sizes | 7.29mm to 0.41mm |

Expanded ID | 0.3-7.0mm |

Wall Thickness | 0.00635-0.05mm |

Shrink Ratio | up to 1.6 : 1 |

Length | up to 1270mm |

You can use this tubing for many medical wires. It fits tightly and stays strong.

Why Use Color Coding in Medical Devices

In medical places, you need to work fast and safe. Color coded PET heat shrink helps you find wires quickly. You do not have to guess. You make fewer mistakes when fixing or setting up devices. Color coding makes your job safer and easier.

Tip: Use the same color system for all your medical wires. This saves time and helps you avoid mistakes.

See how color coding helps your work in the table below:

Improvement Type | Description |

|---|---|

Improved Efficiency | Clear colors save time when you install or fix wires. |

Reduced Errors | Color coding lowers the chance of mistakes during repairs. |

You help keep patients safe with color coded PET heat shrink. You also follow healthcare rules.

PET Material Advantages

You want tubing that lasts and protects wires. PET material gives you many good things. It stands up to heat and chemicals. It stays strong after many uses. PET tubing is very thin, so it does not make devices bulky. It has a high shrink ratio, so it fits wires of many sizes.

PET heat shrink tubing is special because of its strong and heat-resistant features. Look at the table below to see how PET compares to other materials:

Property | Details |

|---|---|

Dielectric Strength | > 4,000 V/mil |

Dielectric Constant | 3.3 |

Dissipation Factor | 0.0025 |

Volume Resistivity | 10^18 Ohm-cm |

Surface Resistivity | 10^14 Ohm/square |

Long-term Temperature | -196°C to 135°C |

Short-term Temperature | Up to 200°C |

Melting Point | 235°C |

Biocompatibility | ISO 10993 |

PET heat shrink tubing keeps its shape in hot and cold. You can use it during sterilization, like autoclaving, with no problem. The tubing does not melt until it gets very hot, at 235°C. It is also safe for medical devices because it is biocompatible.

You pick color coded PET heat shrink for medical wires because it protects well, is easy to spot, and works well in hospitals.

How Medical Grade Heat Shrink Tubing Works

Heat Shrinking Process

Heat shrink tubing covers wires in medical devices. First, you slide the tubing over the wire. Then you heat it up. The tubing gets smaller and fits tightly. This makes a strong seal. It keeps out water and dirt. You can use a heat gun or a hot box. The heat must be just right. Too much heat can hurt the wire.

Here is a table showing the usual heat levels for PET tubing:

Temperature Type | Temperature (°C) | Temperature (°F) |

|---|---|---|

Minimum shrink temperature | 60 | 140 |

Full recovery temperature | >125 | >257 |

Material shrink temp range | 85 to 190 | 185 to 374 |

Recommended hot box range | 149 to 232 | 300 to 450 |

If you use the right heat, the tubing looks smooth. The tight seal keeps wires safe and helps your equipment last.

Application to Medical Wires

You see heat shrink tubing in many medical tools. It is used for catheters and endoscopes. It is also used for surgical tools. The tubing must meet tough safety rules. It passes tests to make sure it is safe for people. It also follows FDA rules and can handle being sterilized.

Standard/Requirement | Description |

|---|---|

Biocompatibility | Compliance with ISO 10993 ensures safety in contact with human tissue. |

Sterilization | Tubing can withstand various sterilization methods, including autoclaving. |

FDA Requirements | Meets strict regulatory standards for medical applications. |

You trust heat shrink tubing because it insulates wires well. It also protects wires from heat and chemicals. This helps your devices work longer and stay safe.

Easy Removal and Maintenance

You keep wires working by doing good maintenance. First, put the tubing over the spot that needs covering. Make sure it goes past the ends a little. Next, use a heat gun set between 150°C and 190°C. Move the heat around so it shrinks evenly. Let the tubing cool down. Check if it fits tight and looks smooth.

Tip: Always test the tubing after you put it on. This helps you find problems early.

You can take off and change the tubing if you need to. Checking and testing often keeps your medical devices safe.

Key Features of Medical Wire Insulation

Mechanical Strength and Durability

You need medical wire insulation that can handle rough use. Medical grade heat shrink tubing protects wires from bending and pulling. It also keeps wires safe from twisting. You can trust its toughness in busy hospitals. PET heat shrink tubing lasts a long time in medical tools. It works better than many other insulation types.

Property | PET Heat Shrink Tubing | Other Insulation Materials |

|---|---|---|

Dielectric Strength | High | Varies |

Physical Toughness | Excellent | Moderate to High |

Shrink Percentage | Higher than FEP | Varies |

Activation Temperature | 60°C (140°F) | Varies |

Application in Battery Insulation | Ideal | Not specified |

You see PET heat shrink tubing work well in medical tools. It keeps wires safe and working for a long time. You do not have to worry about wires breaking or losing their cover.

Chemical Resistance and Biocompatibility

Medical grade heat shrink tubing keeps wires safe from strong chemicals. You use cleaning agents, solvents, and disinfectants every day in hospitals. PET heat shrink tubing does not get damaged by these chemicals. This keeps your wires clean and safe.

Cleaning agents

Solvents

Disinfectants

You also need wire insulation that is safe for people. Biocompatibility is important in every medical device. PET heat shrink tubing meets strict rules for biocompatibility. You see these safety certifications in medical wire insulation:

Regulatory Standard | Description |

|---|---|

ISO 10993 | Sets safety rules for materials that touch the body. |

USP Class VI | Checks safety with tests like injections and toxicity. |

You trust medical grade heat shrink tubing because it keeps wires safe. It also helps keep patients safe. Biocompatibility lets you feel sure when you use it in hospitals.

Thermal Stability and Electrical Insulation

Medical wire insulation must handle heat and electricity. PET heat shrink tubing works well in high heat. You can use it all the time at 150°C (302°F). It can also handle short times up to 200°C (392°F).

Operating Condition | Temperature (°C) | Temperature (°F) |

|---|---|---|

Continuous Operation | 150 | 302 |

Short-term Exposure | 200 | 392 |

You get strong electrical insulation with medical grade heat shrink tubing. It has high dielectric strength. This protects wires in high-voltage medical tools. You use it to cover needles and insulate electrosurgical tools. It also bundles wiring parts together.

Has one of the highest dielectric strengths.

Good for covering needles to protect skin during electrical use.

Insulates electrosurgical tools and other medical wires.

Property | Description |

|---|---|

High Dielectric Strength | Gives strong electrical insulation for high-voltage tools. |

Thin Walls | Makes devices smaller but still keeps wires safe. |

Excellent Electrical Insulation | Stops electrical leaks and keeps medical devices safe. |

You see medical grade heat shrink tubing in catheters and coatings. It is also used for many other wire jobs. It gives you good protection and keeps your devices safe.

Color Coding for Identification

You work faster and safer with color coding on medical wires. Medical grade heat shrink tubing comes in many colors. You can spot wires quickly and make fewer mistakes. Color coding helps you follow safety rules and stay organized.

Benefit | Description |

|---|---|

Immediate visual recognition | Color coding helps you find things fast and not miss anything important. |

Differentiation of product categories | Colors help you know different medical tools right away. |

Distinction of device sizes and types | You can tell sizes and types apart with colors. |

Guidance under pressure | In busy hospitals, color coding helps you make quick choices. |

Prevention of misidentification | Safety labels with colors stop guessing and help you follow rules. |

Tip: Use a clear color system for all your medical wire insulation. You save time and make things safer in every hospital.

You see medical grade heat shrink tubing make your job easier. You get protection, better organization, and safety with every wire you cover.

Benefits of Heat Shrink Tubing in Medical Applications

Enhanced Safety and Reliability

You want medical devices to be safe every time. Heat shrink tubing gives strong insulation and protection. This stops electrical problems and keeps devices working well. You use heat shrink tubing in things like pacemakers. It shields wires from outside harm. The tubing keeps wires from touching metal parts. It also blocks dirt and water. Devices work better and patients stay safer because the tubing helps hold everything together.

Insulation keeps wires safe from electrical problems.

Protection stops wires from touching other things.

Structural support helps devices last longer.

You trust heat shrink tubing because it meets medical rules. It works well in hospitals and helps new ideas. The table below shows how PET heat shrink tubing makes critical care equipment safer and more reliable:

Benefit | Description |

|---|---|

Structural reinforcement | Lowers risk of device failure and keeps patients safe. |

Reliable insulation | Reduces contamination and electrical hazards. |

Long-lasting durability | Keeps devices working and improves patient care. |

Maintains integrity | Supports performance in tough conditions. |

High dielectric strength | Insulates high-voltage parts and prevents failures. |

Organization and Device Appearance

You need to find wires fast in busy hospitals. Marking and color-coding wires with heat shrink tubing helps you work quickly and safely. Color coding makes it easy to spot the right wire. This lowers mistakes. Teamwork gets better because everyone knows the color system. Hospitals use color-coded tubing to keep patients safe and make work easier.

Benefit | Description |

|---|---|

Enhanced Patient Safety | Color-coded labels help you identify important wires fast. |

Streamlined Processes | You save time when you install or fix devices. |

Clear Communication | Color cues help your team work together and avoid errors. |

Improved Patient Engagement | Patients understand their care better with clear color codes. |

Heat shrink tubing also makes devices look neat and professional. You see a smooth finish that builds trust with patients and staff. The tubing makes a seal that shows if someone has opened the device. This means your device is clean and safe. Many companies now use eco-friendly materials to make devices look good and help the planet.

Clean finish gives devices a professional look.

Tamper-evident seals make people trust sterile products.

Eco-friendly options help hospitals protect the environment.

Extended Cable Lifespan

You want medical cables to last a long time. PET heat shrink tubing protects cables from damage and wear. This means you spend less money fixing or replacing them. The tubing keeps cables strong during cleaning and daily use. You see fewer problems and less downtime in your hospital.

PET heat shrink tubing helps you avoid expensive repairs. Its strength means cables stay safe and work well. You also get better catheter protection and safer devices. Biocompatibility testing makes sure the tubing is safe for people. Sterilization keeps everything clean and ready for use.

Tip: Clean your cables often and use good heat shrink tubing. This helps your cables last longer and stay safe.

You use color coded PET heat shrink tubing to cover medical wires. This tubing keeps wires safe and helps you know which wire is which. You make the tubing fit tight by using the right heat and shrink ratio. This helps your medical devices work the right way. PET tubing can go through sterilization and still work well. It also follows tough safety rules, as you can see in the table below:

Regulatory Standard | Description |

|---|---|

USP Class VI | Biocompatibility certification for medical devices. |

ISO 10993 | Safety tests for body contact and exposure. |

FDA Title 21 | Ensures non-toxic materials in medical devices. |

PET is better for the environment than PVC because it is easier to recycle. Think about these things to keep your medical wires safe and working well.

FAQ

What is PET heat shrink tubing used for in medical devices?

You use PET tubing to cover and protect wires. It keeps wires safe and easy to find. This tubing helps hold wires together in medical devices. It meets tough rules and keeps wires safe while you use them.

How does color coding improve safety in medical technology?

Color-coded PET tubing helps you find wires fast. This lowers mistakes and helps you do your job better. Color coding also helps you follow rules and keeps your work neat.

Is PET tubing safe for patient contact?

You can trust PET tubing to be safe for people. Medical grade PET tubing follows strict safety rules. It passes tests for use in medical tools and meets all the needed rules.

Can PET tubing handle sterilization processes?

You use PET tubing because it stands up to heat and chemicals. It keeps its shape when you clean it with heat. This makes it a good pick for medical jobs and keeps it working well.

Why choose PET tubing over other materials?

You pick PET tubing because it is strong and bends easily. It lasts a long time and meets safety rules. PET tubing works in many medical tools and gives good results.

See Also

The Importance of Ultra-Thin PET Tubing in Healthcare

Essential Insights on PET Heat Shrink Tubing for Electronics

Advantages of Using FEP Heat Shrink Tubing in Healthcare

New Developments in FEP Heat Shrink Tubing for Medicine

The Significance of Gamma Radiation Resistant Tubing in Medicine