What is Co-Extruded PET Heat Shrink Tubing and How Does It Work

Co-extruded pet heat shrink tubing has two layers. The outside is a strong PET wall. The inside layer has adhesive. This tubing gives good insulation. It sticks tightly when you heat it. The PET layer protects what is inside. The adhesive layer makes a tight seal. > Makers use a co-extrusion process to join these layers. This makes heat shrink tubing that works well for many things.

Key Takeaways

Co-extruded PET heat shrink tubing has two layers. The outside layer is strong PET. The inside layer is adhesive. The adhesive seals tightly when heated.

The tubing keeps wires and parts safe from water. It also blocks dust, chemicals, and damage. This makes it tough and dependable for hard places.

The tubing shrinks with heat to fit wires closely. The melted adhesive makes a waterproof and tight seal.

This tubing gives great electrical insulation. It also stands up to heat. This makes it good for cars, factories, hospitals, and electronics.

Co-extruded PET tubing lasts longer than other tubing. It also works better in rough conditions. This makes it a smart pick for hard jobs.

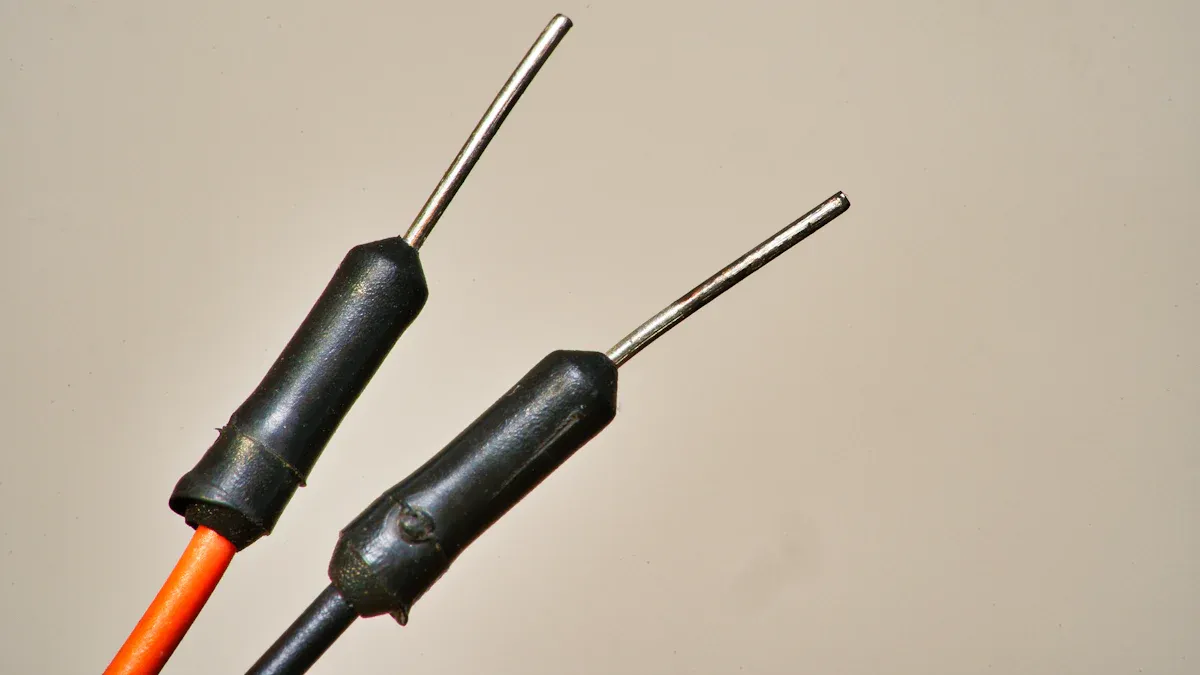

What Is Co-Extruded PET Heat Shrink Tubing

Dual-Wall Structure

Co-extruded PET heat shrink tubing has two layers. The outside is made of PET. This makes the tubing strong and lets it shrink with heat. The inside layer has a hot melt adhesive. When you heat the tubing, the glue gets soft and flows. It wraps tightly around wires or parts. Both layers work together to keep things safe and covered.

The two layers have more benefits than just one layer:

The PET outside is tough and does not wear out fast.

The glue inside sticks well and keeps out water and dust.

The tubing works in hard places and keeps things safe.

The two layers help protect against weather and damage. They also make the tubing last longer and seal better than single-layer tubing.

Here is a table that shows what the PET outside and glue inside can do:

Property | PET Outer Layer Characteristics |

|---|---|

Wall Thickness | Very thin walls (0.0025 – 0.10 mm) |

Tensile Strength | Very strong (>20,000 PSI) |

Electrical Insulation | Good |

Flex Fatigue | Bends many times without breaking |

Surface Finish | Very smooth, hard, and shiny |

Melting Temperature | High melting point (473°F / 245°C) |

Biocompatibility | Safe for people and meets health rules |

Sterilization Methods | Can be cleaned with gas, radiation, or steam (some limits) |

The glue inside:

Melts at a lower heat than the PET.

Sticks to many things.

Keeps out water and dust.

Helps take in some pulling or bending.

This makes co-extruded PET heat shrink tubing great for wires, cables, and small parts.

Co-Extrusion Process

Makers use a co-extrusion process to make this tubing. This means both the PET outside and glue inside are made at the same time. Two machines push out the PET and glue together. This forms one tube with both layers stuck tight.

The steps to make the tubing are:

Get the PET and glue ready.

Use two machines to shape both layers at once.

Put the hot glue in the middle of the PET tube.

Make the tube bigger and control the heat so both layers stay right.

Cool the tube so the layers stay together.

Co-extrusion has many good points:

It lets makers control how thick and strong each layer is.

The tubing can block gases and liquids.

Makers can add special stuff to make the tubing work better.

The tubing comes out strong, bends easily, and is ready for hard jobs.

Co-extruded PET heat shrink tubing is special because it uses the best parts of both layers. This makes the tubing work well for cars, electronics, and medical tools.

How Heat Shrink Tubing Works

Shrinking Mechanism

Heat shrink tubing gets smaller when you heat it. The tubing starts out bigger than what it will cover. When you use heat, the tubing shrinks and wraps around wires or cables. This happens because the plastic, like PET, remembers its small shape. Here is how you use it:

Put the tubing over the part you want to cover.

Use a heat gun or another tool that makes heat.

The tubing will shrink and fit tightly.

The tight fit keeps out dust and dirt. It also holds wires together so they do not move. People use heat shrink tubing for electrical work and fixing cables. It can also help fix broken wire covers.

Tip: Use just enough heat. Too much heat can hurt the tubing or what is inside.

Adhesive Activation

Co-extruded PET heat shrink tubing has a special glue inside. This glue melts when you heat the tubing. As the tubing shrinks, the glue spreads and fills spaces. When the glue cools, it gets hard and sticks well.

The glue does more than just hold things. It keeps water, oil, and chemicals away from wires. The tubing makes a waterproof cover. This cover stops moisture and harsh chemicals from getting in. The glue also helps the tubing stay put, even if the wires bend.

After you put it on, the tubing protects wires from damage and sunlight. It also keeps out heat and cold. The sealed cover stops rust and keeps wires safe. This helps wires and cables last longer.

Many people use heat shrink tubing for both covering and sealing. It works well in tough places. It also makes fixing things easier and better. The two layers, PET and glue, make it stronger than tubing with just one layer.

Note: The glue inside works only when you heat it. Make sure to heat the tubing all over for the best seal.

Co-Extruded PET Heat Shrink Tubing Features

Durability and Protection

Co-extruded PET heat shrink tubing keeps wires and parts safe. The PET outside layer stops cuts and scrapes. This tubing works well even if you handle it roughly. It keeps working in hard places. The adhesive inside gives more safety. It blocks water and dust from getting in. Many people use this tubing to protect cables in cars, machines, and outdoor tools.

The tubing does not break or crack easily.

It blocks dirt and water.

The seal stays tight, even when wires bend.

This strong protection helps wires last longer and work better. The tubing stops short circuits and keeps wires safe from harm.

Chemical Resistance

The PET layer in this tubing blocks many chemicals. It keeps oil, fuel, and cleaners away from wires. The adhesive inside also helps stop chemicals from getting in. This makes the tubing a good pick for places with strong chemicals.

The tubing does not change shape with oil or grease.

It keeps wires safe in factories and cars.

The tubing stops rust and corrosion.

Chemical resistance means the tubing can do hard jobs and still protect.

Electrical Insulation

This tubing gives strong electrical insulation. The PET outside does not let electricity pass through. The adhesive inside fills spaces and covers wires fully. This keeps people and machines safe from shocks.

The tubing covers wires so they do not touch.

It stops power loss and keeps signals clear.

The tubing works for both small and big wires.

Good electrical insulation is important for safe wiring. The tubing gives protection and helps you feel safe.

Heat Shrink Tubing Applications

Electrical and Electronics

Many people use heat shrink tubing for electrical work. It covers wires and connectors to keep them safe. The tubing stops wires from touching and causing problems. It helps fix cables by sealing broken spots. This makes them strong again. On circuit boards, tubing protects small parts from dust and water. These uses help devices last longer and work better.

Tip: Electricians like this tubing because it fits tight. It seals well and keeps out water and dirt.

Automotive and Industrial

In cars and factories, tubing has hard jobs. Workers use it to cover wires, hoses, and sensors. The tubing stands up to heat, oil, and rough use. It also helps fix cables in engines and machines. Co-extruded PET heat shrink tubing has many good points here:

Very high shrink ratio fits many shapes and sizes.

Lower shrink temperature saves time and energy.

Fast shrinking helps make things quicker.

Dielectric protection keeps electrical systems safe.

Wear resistance keeps parts safe for a long time.

Custom sizes and lengths fit many needs.

Linear seamed construction gives a smooth finish.

These features make the tubing a top pick for cars and factories.

Medical and Specialty

Medical tools need safe and clean covers. Co-extruded PET heat shrink tubing meets strict health rules. It covers wires in surgery and test tools. The tubing also protects sensors and small parts in medical machines. PT&C’s tubing meets many important standards, so it is trusted for big jobs.

Certification/Standard | Description/Applicability |

|---|---|

RoHS | Restriction of hazardous substances compliance |

ASTM D149 | Standard test method for dielectric breakdown voltage |

ISO 9001:2015 | Quality management system certification |

CSA Certification | Canadian Standards Association approval |

UL Listing | Underwriters Laboratories safety certification |

FDA Approval | U.S. Food and Drug Administration approval for medical use |

REACH Compliance | Registration, Evaluation, Authorization, and Restriction of Chemicals compliance |

NSF Standards | Public health and safety standards |

ISO 13485 | Medical devices quality management systems |

ISO 14001 | Environmental management system certification |

Mil-Spec | Military specifications compliance |

ASME, SAE, ANSI Standards | Industry-specific engineering and safety standards |

NADCAP | Aerospace industry accreditation |

CE Certification | European conformity marking |

GMP | Good Manufacturing Practice standards |

This tubing works for special jobs like aerospace and defense. Its strong seal and high standards make it a trusted choice for important needs.

Comparison with Other Tubing Types

PET vs. Polyolefin

PET and polyolefin heat shrink tubing both keep wires safe. But they are good at different things. PET tubing can handle high heat and is very strong. Polyolefin tubing bends more easily and can shrink in more ways. The table below shows how they are different:

Property | PET Heat Shrink Tubing | Polyolefin Heat Shrink Tubing |

|---|---|---|

Temperature Resistance | Up to 150°C (302°F) | Best for low-temperature shrink applications |

Mechanical Strength | High tensile strength, abrasion resistant | Good compressive strength, flexible |

Shrink Ratio | 1.1:1 to 3:1 | 1.5:1 to 10:1 (often around 4:1) |

Flexibility | Less flexible | Very flexible, thin-wall |

Cost | Higher | Low to medium |

Application Suitability | Demanding, moderate to high temperature | Delicate, low-temperature, tight tolerance |

Polyolefin tubing is usually cheaper than PET tubing. Many people pick polyolefin because it bends well and costs less. PET tubing costs more, but it protects better in hard places. In hospitals, PET’s higher price is worth it for its strength.

Note: PET tubing is best when you need to block heat, wear, or chemicals. Polyolefin is better for jobs that need more bending and lower heat.

When to Use Co-Extruded PET

Co-extruded PET heat shrink tubing is best for some jobs. Experts use it when they need:

To handle heat up to 150°C.

Strong tubing that does not wear out fast.

Easy to put on and shrinks the same every time.

To last in places with oil, like cars and machines.

Materials that can be recycled to help the planet.

Tight fits for car wires that need to be exact.

Many car and electrical jobs use PET tubing because it is strong and lasts long. PET tubing also helps companies recycle and protect the earth. If you need both insulation and a tight seal, co-extruded PET heat shrink tubing is a good pick.

Co-extruded PET heat shrink tubing is special because it has two layers. The PET outside and the glue inside work together. They help keep things safe, covered, and sealed. Experts say this tubing has many good points:

Benefit Category | Description |

|---|---|

Insulation Properties | It keeps out water, dust, and other things from outside. |

High Shrink Ratio | It can shrink a lot, so it fits many shapes and sizes. |

Chemical Resistance | It does not get ruined by oil, cleaners, or strong chemicals. |

Durability and Strength | It stays strong and lasts a long time, even if you bend it. |

Lightweight and Thin-Walled | It is light and thin, so it works well in small devices. |

Versatility | You can use it in cars, hospitals, and electronics. |

Ease of Use | You can cut it easily and shrink it with heat. |

Cost-Effectiveness | It lasts long, so you do not need to replace it often. |

This tubing gives strong cover and sticks well, so it is good for hard jobs. If you want to know more, you can check out:

Nordson Medical’s guides and product lists

Zeus’s catalogs, brochures, and free samples

Picking the right heat shrink tubing helps keep things safe, strong, and working well.

FAQ

What makes co-extruded PET heat shrink tubing different from single-layer tubing?

Co-extruded PET heat shrink tubing has two layers. The PET outer layer gives strength. The adhesive inner layer creates a tight seal. This design protects wires better than single-layer tubing.

Can co-extruded PET heat shrink tubing be used outdoors?

Yes. The PET layer resists sunlight, water, and weather. The adhesive blocks moisture and dust. This tubing works well for outdoor cables and connections.

How does someone install co-extruded PET heat shrink tubing?

A person slides the tubing over the part. They use a heat gun to shrink it. The tubing tightens and the adhesive melts. This creates a strong, sealed cover.

Is co-extruded PET heat shrink tubing safe for medical devices?

Yes. Many types meet strict medical standards. The tubing protects wires in medical tools. It also resists chemicals and can be sterilized.

What sizes are available for co-extruded PET heat shrink tubing?

Manufacturers offer many sizes. Tubing comes in different diameters and lengths. This helps users find the right fit for wires, cables, or parts.

See Also

Essential Facts About PET Heat Shrink Tubing For Electronics

A Simple Guide To FEP Autoclavable Heat Shrink Tubing

Selecting The Ideal Ultra-Thin PET Heat Shrink Tubing Easily

Uses Of Heat Shrink Tubing For Electrical Wire Insulation

Applications Of FEP Heat Shrink Tubing Across Various Industries