Choosing the Best Nitinol Tubing for Your Application

If you want to pick the best nitinol tubing for your project, you should think about more than just size or cost. Nitinol tubing has special features like shape memory and superelasticity. These features make it popular for medical devices and airplanes. The need for nitinol tubing is growing quickly. This is happening most in healthcare and high-tech fields.

Tip: Look at both the technical features of nitinol and how dependable your tubing supplier is. This will help you get the best results for your projects.

Key Takeaways

Pick nitinol tubing that fits your project's size, strength, and where it will be used. This helps you get the best results.

Find tubing with the right shape memory, superelasticity, and surface finish. This makes sure it is strong and safe.

Pick suppliers who have good certifications and do quality checks. This helps you get nitinol tubing that you can trust.

Try prototyping services to test and improve your tubing before you buy a lot. This lowers risks and helps make better designs.

Think about how long it takes to get your tubing and how much it costs. Talk often with your supplier to stop delays and surprises.

Application Needs

To pick the right nitinol tubing, you need to know what your project needs. Think about the size, how strong it must be, and how much it can bend. Also, think about where the tubing will be used. Medical and industrial uses have different needs. When you know these needs, you can choose tubing that fits your goals.

Dimensions & Tolerances

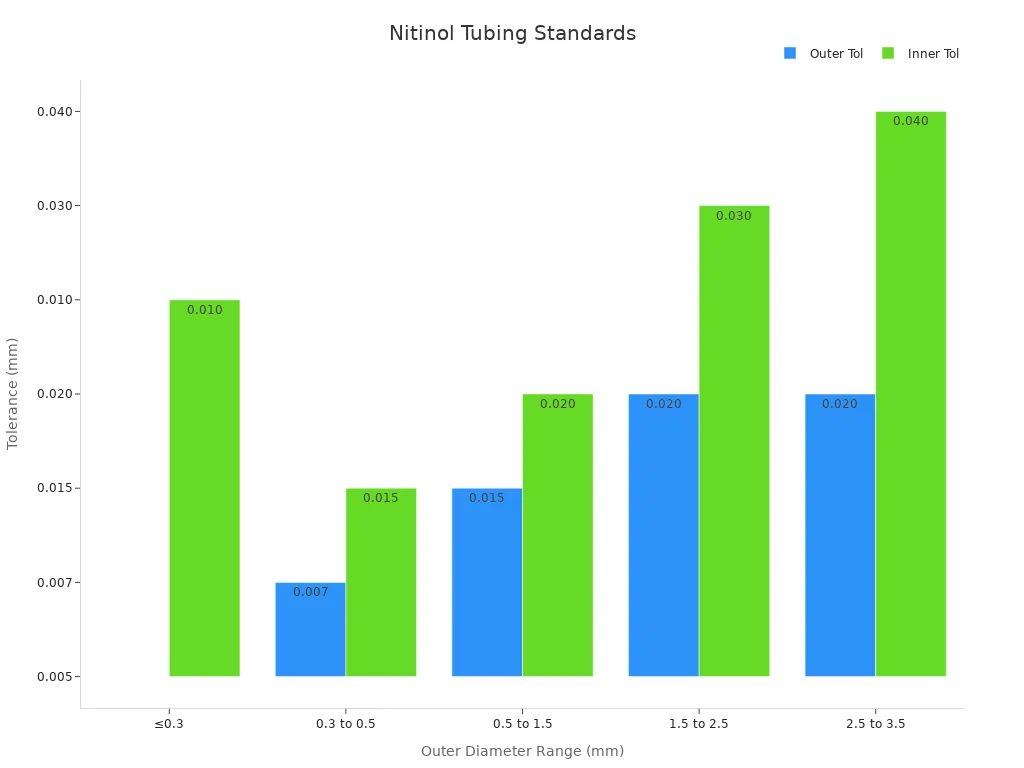

First, decide what size and tolerance you need for your tubing. Nitinol tubing comes in many sizes. The outer diameter can be as small as 0.1mm or as big as 5mm. The wall thickness can go from 0.1mm up to 15mm. Medical devices often need very tight tolerances, like ±0.01mm, to keep people safe. Industrial uses can have a little more room for error. The table below shows the usual standards for nitinol tubing:

Outer Diameter Range (mm) | Outer Diameter Tolerance (mm) | Inner Diameter Tolerance (mm) |

|---|---|---|

≤0.3 | ±0.005 | ±0.010 |

0.3 to 0.5 | ±0.007 | ±0.015 |

0.5 to 1.5 | ±0.015 | ±0.020 |

1.5 to 2.5 | ±0.020 | ±0.030 |

2.5 to 3.5 | ±0.020 | ±0.040 |

Note: You can get special lengths and wall thicknesses for custom devices.

Mechanical & Functional Requirements

Check what mechanical features your project needs. Nitinol tubing can bend and return to its shape. It is also strong and lasts a long time. For medical uses, the tubing should bend many times and not break. Important things to look at are tensile strength, even wall thickness, and how well it resists cracks. A smooth finish, like electropolishing, helps it last longer and work well in the body. For industrial uses, focus on strength and how well it holds up under stress.

Environmental & Regulatory Needs

Think about where the tubing will be used. In medical uses, nitinol tubing touches body fluids, so it must not rust and must be safe for people. Devices must meet rules like ASTM F2063, FDA approval, and ISO 13485. For industrial uses, the tubing might need to handle chemicals or heat. Always make sure your tubing meets the right rules for your job. Following these rules keeps devices safe and working well.

Nitinol Tubing Properties

Shape Memory & Superelasticity

Nitinol tubing is special because it can remember its shape. It also bends and stretches without breaking. If you bend or pull this nickel-titanium alloy, it goes back to its old shape when heated or at body temperature. This happens because nitinol switches between two solid forms called austenite and martensite. Many people use this in medical devices and robots.

The shape memory effect lets nitinol tubing stretch up to 8% when heated. Superelasticity means the tubing can stretch up to 4% at 37 °C and still return to normal. You can bend or squeeze the tubing, and it will snap back. These features make nitinol tubing great for stents and guidewires. It is also good for other devices that need to move inside the body.

Property / Metric | Value / Description |

|---|---|

Superelastic strain limit | Up to 4% at 37 °C |

Shape memory strain limit | Up to 8% (requires heating) |

Tensile strength | 500 - 900 MPa |

Fatigue resistance | Up to 400 million cycles |

Activation temperature | Around body temperature (37 °C) |

Tip: Shape memory and superelasticity help nitinol tubing last longer and work better in tough places.

Medical grade ASTM F2063 nitinol tubing goes through many tests. These tests check for rust and how long the tubing lasts. Labs also check the chemical makeup and how the tubing changes shape. This makes sure you get nitinol tubing that works well every time.

A study tested how well the shape memory effect works. Ten nitinol wires were bent into a 90-degree curve. After heating, the wires went back to a radius of 65.1 mm, which was very close to the goal. This shows nitinol tubing works the same way each time.

Grades & Surface Modifications

You can pick from different grades of nickel-titanium alloy for your tubing. Each grade has its own flexibility, strength, and temperature for changing shape. The best grade depends on what you need. For example, heart devices need tubing that can bend many times and change shape at the right temperature.

Surface changes can make the tubing work better. Chemical etching can make the surface rough or smooth. For example, H2SO4/H2O2 keeps the tubing smooth. HCl/H2SO4 makes it rougher. NH4OH/H2O2 adds oxides and makes the tubing attract water. These changes help the tubing work better with body tissues or fluids.

Laser polishing is another way to improve nitinol tubing. CO2 laser polishing can make the tubing 91% smoother. This helps stop irritation or blood clots. Femtosecond laser polishing can change the surface, but it does not always make it smoother.

Material | Tensile Strength Range (MPa) | Key Characteristics |

|---|---|---|

Nitinol Tubing | 500–900 | Superelasticity, shape memory effect |

Stainless Steel | 600–1100+ | Cost-effective, strong |

Titanium Alloys | 900–1200 | High strength-to-weight ratio |

Note: New ways to make nitinol tubing, like the TM-1 process, make it cleaner and stronger. This means fewer problems and better tubing.

Studies show that the inside structure of different nickel-titanium alloy grades matters. Some grades have smaller bits inside, which helps the tubing last longer. You should ask your supplier which grade and surface treatment are best for you.

Biocompatibility & Corrosion Resistance

Biocompatibility and corrosion resistance are very important for nitinol tubing in medical devices. The nickel-titanium alloy forms a thin oxide layer on the outside. This layer stops nickel from leaking out, which is good because nickel can be harmful.

Electropolishing takes away dirt and makes the tubing smooth. This lowers the chance of blood clots and makes the tubing safer in the body. Research shows that electropolished nitinol tubing lets out less nickel and does not rust as easily. This means your devices will last longer and be safer.

Some nickel-titanium alloy tubing has a porous structure. This makes a special ceramic-metal layer that stops rust and helps the body accept the tubing. The porous design also lets fluids move through, which can help healing.

Callout: Always make sure your nitinol tubing meets the rules for biocompatibility and corrosion resistance. This keeps your devices safe and working well.

Clinical trials, like MISAGO 1 and ORION, show that nitinol stents work better than other materials. These stents stay open longer and do not break, even after many uses. Surface treatments like electropolishing and chemical passivation help the tubing work better and keep patients safe.

Tubing Options

Standard & Custom Sizes

You can pick standard or custom nitinol tubing sizes for your needs. Standard sizes follow rules like ASTM F2063 and ISO 13485. They have tight tolerances, as small as ±0.0005 inches. Custom tubing can be made with even smaller diameters and thinner walls. This is important for medical devices that must fit in tiny spaces.

Precision methods, like laser cutting and 3D printing, help make tubing with exact shapes.

Quality checks can find changes as small as ±5 microns.

Custom tubes can have special features, like sensors or coatings for better use.

Standard nitinol tubing is easier to find but comes in fewer sizes. Custom tubing takes more time and costs more money. But it is made for special uses in advanced projects. More people want low volume nitinol tubing with smaller sizes. This is especially true for procedures that do not need big cuts.

Nitinol Laser Cut Hypotubes

Nitinol laser cut hypotubes give many benefits for your projects. These hypotubes use laser cutting for very high precision. This makes complex shapes and smooth surfaces. These things are important for medical devices.

Performance Aspect | Nitinol Laser Cut Hypotubes (LCHTs) Advantages |

|---|---|

Precision Manufacturing | Laser cutting enables tight tolerances and intricate features. |

Clinical Outcomes | Studies show 20% better recovery and fewer complications. |

Fatigue Resistance | Superior durability under repeated use. |

Corrosion Resistance | Electropolished surfaces resist corrosion up to 1000 mV. |

Biocompatibility | Safe for the body, reducing device failure risks. |

You can use nitinol laser cut hypotubes in many ways. Some examples are stents, catheters, and robotic tools. These hypotubes work better than regular tubing. They use advanced making methods and the special features of nitinol. You get better device function, better patient results, and more reliable use.

Wall Thickness & Finishes

Wall thickness and surface finishes are very important for nitinol tubing. You can control wall thickness within 0.01 mm. This helps you get the right strength and flexibility for your needs.

Metric | Description and Impact |

|---|---|

Tensile Strength | 500–900 MPa, showing strong and durable tubing. |

Cycles to Failure | Up to 10 million cycles, meaning high fatigue resistance. |

Breakdown Potential | Up to 1000 mV after electropolishing, for excellent corrosion resistance. |

Cutting Tolerances | ±10 microns, ensuring precise and consistent wall thickness. |

Surface treatments, like electropolishing and passivation, make tubing smoother and safer. These finishes lower the risk of corrosion and nickel release. This is very important for medical uses. Precision methods, like laser cutting and ultrasonic gauging, help keep wall thickness even. This can double or triple how long your hypotubes last.

Tip: Always pick the right wall thickness and finish for your needs. This helps your low volume nitinol tubing last longer and work better.

Supplier Selection

Picking the right supplier for nitinol tubing is very important. You should not only think about price or delivery time. It is better to look at things like certifications, quality, prototyping, and support. These things help you get safe and reliable tubing for your project.

Certifications & Quality

Certifications show a supplier follows strict rules for safety and quality. When you choose a supplier, check if they have certifications like ISO 13485 for medical devices or AS9100 for airplanes. These certifications mean the supplier uses good quality systems and follows world standards.

ISO 13485:2016 checks every step, from raw materials to finished tubing. It looks at paperwork, tracking, and risk control.

AS9100 and IATF 16949 are needed for airplane and car parts.

FDA registration and astm f2063 certifications show the supplier meets U.S. and world rules.

Other certifications are ISO 9000, ISO 14000, REACH, RoHS, and Conflict Minerals Disclosure.

Suppliers with these certifications use new ways to make tubing, like laser cutting and precision drawing. They also use tests like ultrasonic and eddy current checks to find problems without breaking the tubing. They measure the tubing to make sure it is the right size, sometimes as close as ±0.0005 inches. They also test strength, bending, and how long the tubing lasts.

Tip: Certified suppliers usually have better quality checks, less waste, and find problems faster. This helps you get tubing that works well and lasts a long time.

A supplier with strong certifications can sell in more places and grow faster. You can trust their tubing for hard jobs, like medical devices and airplane parts. They keep good records, use computers for audits, and follow strict rules at every step.

Nitinol Tubing Prototyping Service

A good prototyping service helps you turn ideas into real products. Prototyping lets you test designs, check fit, and see how tubing works before you buy a lot. This is very important for medical devices, where safety and how it works matter most.

The best suppliers make prototypes fast and send samples quickly.

They use special tools, like diamond dies and laser cutters, to make custom shapes.

You can visit their factories to see how they work and check quality.

Suppliers like AccuPath and Resonetics let you try prototyping and give expert help.

Customers often say good things about suppliers who send quality tubing on time. Stories show that suppliers with strong prototyping skills can make superelastic nitinol parts for hard medical jobs. These suppliers help you test tubing before you order a lot.

Prototyping services should have:

Same quality in every batch

Fast turnaround times

Custom alloy mixes

Fatigue testing and special processing

Full paperwork and rule-following

Studies show that some ways of making tubing, like TM-1, make tubing last two or three times longer than other ways. This means your prototypes will last longer and work better. Models that use microstructure and inclusion size help make sure you get good tubing every time.

Callout: Always pick a supplier with a good nitinol tubing prototyping service. This lowers risk and helps you make better products faster.

Support & Reliability

You need a supplier who helps you at every step. Good support means clear answers, quick replies, and help with problems. Reliable suppliers keep your project moving and fix issues fast.

Pick suppliers who answer custom requests quickly.

See if they give technical help and fix problems.

Ask about their return rules and warranty choices.

Reliable suppliers use tight controls to make sure tubing is right for you. They test for strength, biocompatibility, and fatigue resistance. They follow ISO 13485 and FDA 21 CFR Part 820 to keep quality high and problems low.

Supply chain reliability is important too. The best suppliers watch inventory in real time, use smart warehouses, and have backup plans to stop delays. They deliver tubing on time, even for urgent prototypes.

Support Metric | What to Look For |

|---|---|

Communication | Fast, clear, and helpful responses |

Technical Assistance | Expert advice on tubing and prototyping |

Delivery Times | On-time shipments, even for small batches |

Quality Control | Regular testing and strict process monitoring |

Customization | Willingness to make special sizes or finishes |

Note: The best suppliers show they are reliable with certifications, strong quality checks, and new ways to make tubing. This helps you feel safe and makes your project do well.

Practical Considerations

Lead Time & Pricing

When picking Nitinol tubing, think about how long it takes to get and how much it costs. These things can change fast because of the market and supply chain problems. Nitinol tubing costs more than other metals. This is because making it needs special machines and pure materials. Every step must be watched closely. If nickel or titanium prices go up, Nitinol tubing gets more expensive too.

More people want Nitinol tubing, especially for medical devices that need superelasticity and biocompatibility.

Trusted companies like AccuPath make sure tubing is safe and exact, but this can raise the price.

Nitinol tubing can be made into tricky shapes and fit patients’ needs, so many people think it is worth the higher cost.

The FDA and EMA have strict rules, so only the best tubing is sold.

Prices can change if raw materials cost more, shipping is slow, or new rules come out. The table below shows how these things can change your order:

Factor | Impact on Procurement |

|---|---|

Raw Material Price Surges | Raises production costs by 10-12% |

Lead Time Extensions | Delays shipments by 8-12 weeks |

Regulatory Delays | Adds months to market entry and increases costs |

Shipping Costs | Raises inventory costs and can delay delivery |

Pricing Volatility | Causes shipment delays and order changes |

Geopolitical Risks | Shifts sourcing to higher-cost regions |

Tip: Plan early and talk to your supplier about possible delays or price changes. Buying in bulk and planning ahead can help you save money and avoid running out.

Communication & Support

Good communication and support from your supplier are very important. You want a supplier who answers fast and gives clear updates about your order. Many top suppliers have customer support all day and night. They give you an account manager to help you with every step.

Special support teams fix problems quickly and give expert help.

You get updates on your order, so you can plan your project.

After you buy, you get tips for care and options for replacements. This shows the supplier wants you to do well.

If you work with teams in other countries, multilingual support helps a lot.

Good suppliers tell you how long your order will take and answer problems fast. They have easy return rules and strong warranties. This helps you feel safe and keeps your project going.

Note: Good communication and support help you avoid delays and fix problems early. Always pick a supplier who cares about your time and needs.

Picking the best Nitinol tubing means you need to match what your project needs with the right tubing features. You should also choose a supplier you can trust. Always look for certifications to make sure the tubing is safe and high quality. Ask for samples so you can check the tubing yourself. Get all the paperwork from your supplier. Talk to experts if you need help picking the right tubing. The table below lists important steps to help you make a smart and safe choice:

Key Aspect | Why It Matters |

|---|---|

Certified Standards | Makes sure medical devices are safe and good quality |

Surface Treatments | Helps the tubing work well in the body and stops rust |

Nickel Release Testing | Makes sure nickel stays much lower than FDA rules |

Checks that the tubing is strong and safe | |

Documentation & Traceability | Helps follow rules and keeps patients safe |

Tip: Work with your supplier and talk often to get the best tubing for your project.

FAQ

What is the main benefit of Nitinol tubing?

Nitinol tubing can return to its original shape after bending. You get strong, flexible tubing that works well in many devices. This makes it popular for medical and high-tech uses.

How do you choose the right Nitinol tubing size?

You should measure the space where you will use the tubing. Check the needed diameter and wall thickness. Ask your supplier for help if you need special sizes.

Is Nitinol tubing safe for medical use?

Yes! Nitinol tubing is safe when it meets medical standards like ASTM F2063 and ISO 13485. Always ask for proof of testing and certifications from your supplier.

Can you get custom Nitinol tubing?

You can order custom Nitinol tubing for special projects. Many suppliers offer custom sizes, finishes, and features. Custom tubing may cost more and take longer to make.

How do you care for Nitinol tubing?

Store tubing in a dry, clean place.

Avoid bending it too much.

Clean with mild soap and water.

Check for damage before each use.

Tip: Good care helps your tubing last longer and work better.

See Also

A Detailed Guide To Selecting Proper Nitinol Tubing

The Manufacturing Process Of Nitinol Tubing For Medicine