How to Choose Nitinol Tubing for Torque Resistance

Selecting the right nitinol tubing with enhanced torque resistance is critical for applications demanding precision and durability. The material’s unique properties, such as superelasticity and shape memory, make it ideal for high-performance tools. However, ensuring consistent quality requires partnering with a manufacturer that adheres to stringent standards. AccuPath stands out as a leader in this space. Their ISO 13485 certification and FDA/QSR compliance guarantee superior nitinol tubing with enhanced torque resistance for medical and industrial needs. Advanced testing, including ultrasonic and X-ray evaluations, further ensures reliability and safety.

AccuPath’s expertise minimizes risks like impurity-induced corrosion, which can compromise torque resistance. For applications where performance and safety are non-negotiable, choosing a trusted manufacturer is not just an option—it’s essential.

Key Takeaways

Pick nitinol tubing from trusted makers like AccuPath for good quality.

Test samples and prototypes to check strength and flexibility before deciding.

Adjust wall thickness and size to improve strength and performance.

Choose tubing with a smooth finish, like electropolishing, for longer use and less friction.

Learn about nitinol’s special traits, like bending back and rust resistance, to use it better.

Importance of Torque Resistance in Nitinol Tubing

Defining Torque Resistance

Torque resistance refers to a material's ability to withstand twisting forces without deformation or failure. Engineers define torque as a twisting force that causes rotation, represented by the symbol τ (tau). It is measured in units such as Newton meters (N⋅m) or foot-pounds (ft/lbs), depending on the region. In nitinol tubing, torque resistance plays a critical role in ensuring durability and precision during rotational movements.

Several parameters are used to measure torque resistance in engineering applications:

Torque is a vector quantity, meaning it has both magnitude and direction.

Total driving resistance evaluates the torque of all driven axles, essential for vehicle dynamics.

Mechanical work is computed from driving resistance over a duty cycle, aiding engine load calculations.

Bearing losses indicate rotational inertia and are measured using torque sensors.

Measurement Method | Description |

|---|---|

Strain Gage Sensors | Measure torque through electronic outputs in rotary torque sensors. |

Brushless/Inductive Sensors | Enable contactless measurement of angle and RPM, reducing wear and maintenance needs. |

Applications Requiring Enhanced Torque Resistance

Enhanced torque resistance is vital in applications demanding high precision and reliability. In the medical field, nitinol tubing is used in guidewires and catheters, where torque control ensures accurate navigation through complex anatomical pathways. Industrial applications, such as robotics and precision tools, rely on nitinol tubing for its ability to maintain performance under repeated twisting forces.

For example, robotic arms equipped with nitinol tubing benefit from its superelasticity, allowing smooth and controlled movements. Similarly, precision tools used in manufacturing require tubing that can endure high torque without compromising accuracy. These applications highlight the importance of selecting nitinol tubing with optimized torque resistance to achieve superior performance.

Role of Nitinol’s Properties in Torque Resistance

Nitinol’s unique properties make it an ideal material for applications requiring torque control. Its superelasticity allows the tubing to recover its original shape after deformation, ensuring consistent performance during rotational movements. The nickel-titanium composition provides exceptional strength and flexibility, enabling the tubing to withstand high torque forces without breaking.

Additionally, nitinol’s corrosion resistance enhances its longevity, making it suitable for environments where exposure to moisture or chemicals is common. These properties, combined with its shape memory effect, ensure that nitinol tubing delivers reliable torque resistance across diverse applications. By leveraging these advantages, manufacturers can create high-performance tools that meet the demands of modern industries.

Material Properties of Nitinol Tubing

Superelasticity and Shape Memory Benefits

Nitinol stands out for its remarkable superelasticity and shape memory properties, making it a preferred material for high-performance applications. Superelasticity allows nitinol to recover from significant deformations without permanent damage. This characteristic is particularly valuable in dynamic environments where flexibility and durability are essential. For example, orthodontic devices like copper niti archwire rely on nitinol’s ability to maintain consistent force over extended periods, ensuring effective and predictable results.

The shape memory effect further enhances nitinol’s versatility. When heated, nitinol can return to its original form, enabling innovative applications such as self-expanding stents in the medical field. These stents adapt to the body’s temperature, expanding precisely where needed to restore blood flow. This unique combination of properties ensures that nitinol delivers unmatched performance in both medical and industrial settings.

Key material specifications include:

Shape Memory Effect: Enables nitinol to revert to its original shape upon heating.

Superelasticity: Allows recovery from large deformations, ideal for flexible applications.

Biocompatibility: Ensures safety for long-term medical implants.

Corrosion Resistance: Withstands harsh environments, extending its lifespan.

Nickel-Titanium Composition and Performance

The nickel-titanium composition of nitinol is the foundation of its exceptional performance. A precise balance of these two elements creates the alloy’s unique properties, including its superelasticity and shape memory. Vacuum melting plays a critical role in achieving this balance by removing impurities and ensuring alloy purity. This meticulous process allows manufacturers to produce high-quality nitinol tubing that meets the stringent demands of modern applications.

Engineers must carefully consider the trade-offs between stiffness and flexibility when designing nitinol components. For instance:

A higher Young’s Modulus increases stiffness but may reduce flexibility.

Lower stiffness enhances flexibility but may compromise structural integrity.

Achieving the right balance ensures optimal performance for specific applications.

This composition also makes nitinol an ideal material for copper niti archwire, where consistent force and durability are crucial. Its ability to maintain performance under stress ensures reliable results in orthodontic treatments and other precision applications.

Corrosion Resistance and Longevity

Nitinol’s corrosion resistance is a defining feature that ensures its longevity in challenging environments. This property is especially critical in medical applications, where nitinol tubing often comes into direct contact with human tissue. Electropolished nitinol tubing demonstrates superior corrosion resistance, with a breakdown potential of up to 1000 mV, compared to oxidized tubing, which has a much lower breakdown potential of -117 mV. This enhanced resistance minimizes the risk of device failure, ensuring long-term reliability.

Surface Finish | Breakdown Potential (mV) |

|---|---|

Oxidized Tubing | -117 |

Electropolished Tubing | Up to 1000 |

The durability of nitinol also makes it suitable for marine and chemical applications, where exposure to moisture and corrosive substances is common. Its ability to maintain strength and flexibility over time ensures consistent performance, even in the harshest conditions. This reliability is why nitinol is a trusted material for copper niti archwire and other high-performance tools.

Tip: Choosing nitinol tubing with a high-quality surface finish, such as electropolishing, can significantly enhance its corrosion resistance and longevity, ensuring optimal performance in demanding applications.

Design Considerations for Enhanced Torque Resistance

Wall Thickness and Diameter Optimization

The wall thickness and diameter of nitinol tubing significantly influence its torque resistance and overall performance. Engineers must carefully balance these dimensions to achieve the desired mechanical properties. Thicker walls provide greater resistance to twisting forces, making the tubing more durable under high torque conditions. However, excessive thickness can reduce flexibility, which may limit its application in areas requiring enhanced flexibility.

Optimizing the diameter is equally important. A larger diameter increases the tubing's ability to withstand torque, while a smaller diameter enhances maneuverability. For example, in medical applications like guidewires, a smaller diameter allows precise navigation through narrow anatomical pathways. On the other hand, industrial tools often benefit from larger diameters to handle higher torque loads.

Tip: Collaborating with a trusted manufacturer ensures precise control over wall thickness and diameter, resulting in nitinol tubing tailored to specific performance requirements.

Surface Finish and Its Impact on Torque

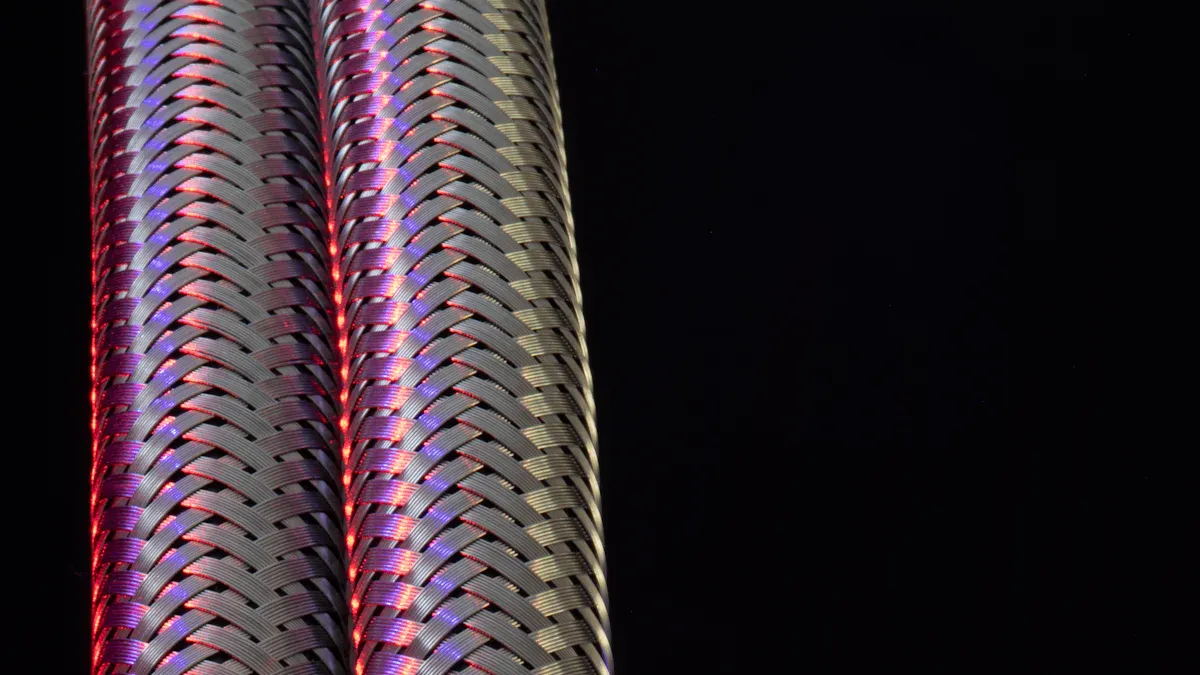

The surface finish of nitinol tubing plays a crucial role in its torque resistance and longevity. A smooth, polished surface reduces friction during rotational movements, enhancing the tubing's performance. Electropolishing, a common finishing technique, removes surface imperfections and creates a uniform finish. This process not only improves torque resistance but also enhances the tubing's corrosion resistance.

Rough or uneven surfaces can lead to stress concentrations, increasing the risk of material failure under high torque. For applications requiring consistent performance, such as robotic arms or precision tools, a high-quality surface finish is essential. Manufacturers like AccuPath use advanced finishing techniques to ensure their nitinol tubing meets the highest standards of quality and reliability.

Surface Finish Technique | Benefits |

|---|---|

Electropolishing | Enhances corrosion resistance and reduces surface roughness. |

Mechanical Polishing | Improves surface uniformity and minimizes stress concentrations. |

Customization for Specific Applications

Customization is key to maximizing the performance of nitinol tubing in diverse applications. Each industry has unique requirements, and a one-size-fits-all approach rarely delivers optimal results. For instance, medical devices like catheters may require tubing with enhanced flexibility and precise torque control. In contrast, industrial tools might prioritize durability and high torque resistance.

Manufacturers can customize nitinol tubing by adjusting its dimensions, surface finish, and alloy composition. Advanced manufacturing techniques, such as laser cutting and precision machining, enable the creation of tubing tailored to specific needs. This level of customization ensures that the tubing performs reliably, even in the most demanding environments.

Call to Action: Partnering with a reliable manufacturer like AccuPath ensures access to fully customized nitinol tubing designed to meet your exact specifications.

Application-Specific Insights

Medical Applications: Nitinol Guidewires and Catheters

Nitinol guidewires and catheters have revolutionized medical procedures by delivering unmatched precision and reliability. Their superelasticity allows them to navigate complex anatomical pathways with ease, ensuring accurate placement during procedures. The biocompatible guidewire design minimizes risks of adverse reactions, making them ideal for long-term use in sensitive environments.

Clinical studies highlight their effectiveness. The Silverway nitinol guidewire achieved a 98% success rate in vessel crossing, while catheters demonstrated a 92% delivery success rate. These tools also reduce procedural complications, leading to better procedural outcomes and shorter recovery times for patients. Advanced designs enable precise mapping and ablation, ensuring complete treatments and improved patient care.

Tip: Choosing nitinol guidewires with optimized torque resistance ensures smoother navigation and enhances procedural outcomes, especially in challenging anatomical regions.

Industrial Applications: Robotics and Precision Tools

In industrial settings, nitinol tubing plays a pivotal role in robotics and precision tools. Its ability to withstand repeated twisting forces without deformation makes it indispensable for applications requiring high torque performance. Robotic arms equipped with nitinol tubing benefit from smooth, controlled movements, enhancing operational efficiency.

Precision tools, such as those used in manufacturing, rely on nitinol’s durability to maintain accuracy under stress. The material’s corrosion resistance ensures longevity, even in harsh environments. By leveraging nitinol’s unique properties, industries can achieve superior performance and reliability in their operations.

Call to Action: Partnering with manufacturers who specialize in nitinol tubing customization ensures tools and robotics meet exact performance requirements.

Matching Tubing Design to Application Needs

Matching nitinol tubing design to specific application needs is essential for optimizing performance. Engineers must consider factors like wall thickness, diameter, and surface finish to achieve the desired torque resistance. For example, medical applications often require tubing with smaller diameters for navigating complex anatomical pathways, while industrial tools benefit from larger diameters to handle higher torque loads.

A comparative analysis confirms that geometric optimization significantly enhances torque performance. Adjusting inlet and outlet angles in components like turbines and stators improves efficiency and torque ratios. Similarly, precise control over tubing dimensions ensures reliable performance across diverse applications.

OD Tolerances | Wall Thickness | WT Tolerances | |

|---|---|---|---|

> 0.80mm | ±0.005mm | 0.05–0.12mm | ±0.0075mm |

0.801-2.80mm | ±0.010mm | 0.13–0.26mm | ±0.010mm |

0.281-6.00mm | ±0.015mm | 0.27–0.40mm | ±0.013mm |

6.010-12.00mm | ±0.020mm | 0.41–0.60mm | ±0.020mm |

12.010-15.00mm | ±0.030mm | 0.61–1.00mm | ±0.030mm |

Note: Collaborating with manufacturers who monitor compliance metrics like temperature, pressure, and material composition ensures tubing meets industry standards and delivers optimal performance.

Best Practices for Selecting Nitinol Tubing

Partnering with Reliable Manufacturers Like AccuPath

Selecting the right manufacturer is crucial when sourcing nitinol tubing. Reliable manufacturers, such as AccuPath, ensure consistent quality by adhering to rigorous production standards. Their expertise in nitinol processing guarantees tubing with optimal torque resistance and durability. Manufacturers like AccuPath also offer advanced customization options, enabling engineers to tailor tubing to specific application needs.

Tip: Collaborating with manufacturers who conduct multi-modal characterization of nitinol’s microstructure and fatigue performance ensures superior product reliability. Testing for clinical applications, such as 600 million cycles for heart valve designs, provides confidence in the tubing’s long-term performance.

Evaluating Samples and Prototypes

Evaluating samples and prototypes is a critical step in selecting nitinol tubing. Engineers should assess the tubing’s mechanical properties, such as torque resistance and flexibility, under conditions that mimic real-world applications. Prototypes allow for early identification of potential issues, reducing the risk of costly design changes later.

Testing should include fatigue performance and corrosion resistance to ensure the tubing meets application-specific requirements. For example, nitinol tubing used in medical devices must withstand repeated stress without compromising safety or performance. By thoroughly evaluating samples, engineers can make informed decisions and select tubing that delivers consistent results.

Ensuring Compliance with Industry Standards

Compliance with industry standards is essential for ensuring the safety and performance of nitinol tubing. Standards such as ASTM F2063 and ISO 10993-1 provide guidelines for mechanical properties, corrosion resistance, and biocompatibility. Manufacturers that meet these standards demonstrate their commitment to quality and reliability.

Standard | Description |

|---|---|

ASTM F2063 | Specifies mechanical properties and corrosion resistance for nitinol tubing. |

ISO 10993-1 | Mandates biocompatibility testing for materials used in medical devices contacting bodily fluids. |

FDA/EMA Compliance | Ensures safety and performance in medical applications, influencing design and production. |

Selecting tubing from manufacturers who comply with these standards ensures that the product meets the rigorous demands of modern applications. This approach minimizes risks and guarantees long-term reliability.

Choosing the right Nitinol tubing for torque resistance involves understanding critical factors like material properties, design optimization, and application-specific requirements. These elements ensure the tubing performs reliably under demanding conditions.

Key Takeaway: Partnering with a trusted manufacturer like AccuPath guarantees access to high-quality, customizable Nitinol tubing. Their expertise ensures compliance with industry standards and delivers superior performance.

For applications where precision and durability are essential, AccuPath provides the confidence needed to achieve exceptional results.

FAQ

What makes Nitinol tubing ideal for torque resistance applications?

Nitinol tubing offers unmatched superelasticity and shape memory properties. These features ensure durability and precision under twisting forces. Its nickel-titanium composition provides exceptional strength, while corrosion resistance guarantees long-term reliability. These qualities make it indispensable for medical and industrial applications.

How does AccuPath ensure the quality of Nitinol tubing?

AccuPath adheres to ISO 13485 standards and FDA/QSR compliance. Their advanced testing methods, including ultrasonic and X-ray evaluations, eliminate impurities and ensure consistent performance. Their expertise guarantees tubing tailored to meet specific torque resistance requirements.

Can Nitinol tubing be customized for unique applications?

Yes, manufacturers like AccuPath offer customization options. Engineers can adjust wall thickness, diameter, and surface finish to match application needs. Advanced techniques like laser cutting ensure tubing performs optimally in medical devices, robotics, and precision tools.

Why is surface finish important for torque resistance?

A smooth surface finish reduces friction during rotational movements, enhancing torque resistance. Techniques like electropolishing remove imperfections, improving durability and corrosion resistance. This ensures consistent performance in demanding environments.

What industries benefit most from Nitinol tubing?

Medical and industrial sectors rely heavily on Nitinol tubing. In healthcare, it improves guidewire navigation and catheter precision. In industry, it enhances robotic arm movements and precision tool durability. Its versatility makes it a preferred choice across diverse applications.

See Also

Choosing The Ideal Nitinol Tubing Supplier For Your Requirements

A Comprehensive Approach To Selecting The Perfect Nitinol Tubing

Analyzing The Strength Differences Between Nitinol And Stainless Steel Tubing

The Manufacturing Process Of Nitinol Tubing For Medical Uses

The Importance Of Nitinol Tubing In Modern Medical Technologies