How to Choose the Right PET Heat Shrink Tubing for Your Needs

PET heat shrink tubing plays a critical role in protecting and insulating wires, cables, and electronic components. Selecting the appropriate tubing ensures durability, efficiency, and safety in various applications. Factors like size, material properties, and shrink ratios directly impact its performance. Application-specific requirements also influence the choice, such as thermal resistance or flexibility. Customizable PET heat shrink tubing offers tailored solutions to meet unique needs, making it ideal for industries requiring precision and reliability. Ensuring compliance with industry standards further guarantees optimal functionality.

Key Takeaways

Pick the right size PET heat shrink tubing for a good fit. The tubing's width should match the widest part of the item.

Check the material and shrink ratios to match your needs. Look for tubing that handles heat and resists chemicals.

Think about what your project needs. Different fields, like cars or healthcare, need special tubing features.

Make sure the tubing follows safety rules and quality standards. This is very important for medical, car, and airplane uses.

Ask experts for help with custom solutions. They can guide you to tubing that fits your needs perfectly.

Understanding PET Heat Shrink Tubing

What is PET Heat Shrink Tubing

PET heat shrink tubing is a protective material made from polyethylene terephthalate (PET). It is designed to shrink tightly around objects when exposed to heat, creating a secure and insulating layer. This tubing is widely used in industries due to its ability to conform to various shapes and sizes, ensuring a snug fit. Its high tensile strength and resistance to chemicals make it a reliable choice for applications requiring durability and protection. PET heat shrink tubing also offers excellent electrical insulation, making it suitable for safeguarding wires and electronic components.

Key Benefits of PET Heat Shrink Tubing

PET heat shrink tubing provides several advantages that make it a preferred choice across industries:

Durability: Its robust structure resists abrasion, punctures, and impacts, ensuring long-term protection.

Chemical Resistance: It shields against oils, solvents, and corrosive substances, maintaining integrity in harsh environments.

Thermal Stability: The tubing operates effectively at temperatures up to 150°C (302°F) and withstands short-term exposure to 200°C (392°F).

Electrical Insulation: With a dielectric strength exceeding 4,000 V/mil, it ensures safety in electrical applications.

Cost-Effectiveness: Compared to alternatives like FEP, PET tubing offers a budget-friendly solution without compromising quality.

Property/Application | Description |

|---|---|

Mechanical Strength | Exhibits high tensile strength and abrasion resistance, suitable for demanding applications. |

Chemical Resistance | Resistant to a wide range of chemicals, oils, and solvents, ensuring protection from corrosive substances. |

Thermal Stability | Can withstand continuous operating temperatures up to 150°C (302°F). |

Tight Conformity | Conforms tightly to the shape of the object, providing a secure and protective covering. |

Cost-Effectiveness | Generally more cost-effective compared to FEP, making it attractive for budget-conscious applications. |

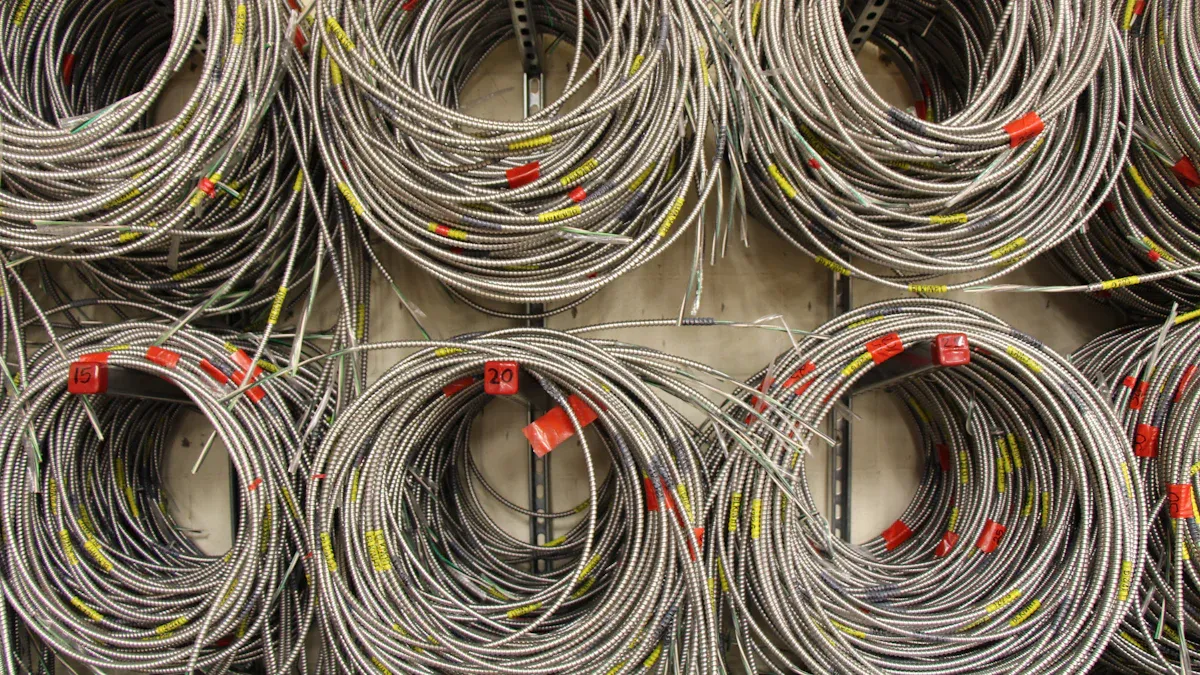

Common Applications of Heat Shrinkable Tubing

Heat shrinkable tubing serves a variety of purposes across industries. Its versatility makes it indispensable in applications requiring insulation, protection, and structural reinforcement.

Electronics: PET tubing insulates wires and cables, preventing electrical shorts and damage.

Medical Devices: It maintains clarity and flexibility after sterilization, ensuring safety and durability in sterile environments.

Automotive: The tubing protects wiring harnesses from moisture, chemicals, and abrasion, enhancing vehicle reliability.

Industrial Equipment: It shields components from corrosive substances and mechanical stress, ensuring longevity.

Aerospace: PET tubing provides thermal stability and electrical insulation, meeting the stringent requirements of aerospace applications.

PET heat shrink tubing enhances the structural integrity of components by conforming tightly to their shape. Its ability to endure repeated sterilization processes and exposure to harsh cleaning agents makes it ideal for medical and industrial settings.

Key Factors for Choosing Customizable PET Heat Shrink Tubing

Determining the Right Size and Fit

Choosing the correct size is crucial for ensuring the tubing performs effectively. The diameter of the polyethylene heat shrinkable tubing must match the largest part of the component it will cover. After shrinking, the recovered diameter should be smaller than the smallest part of the component to guarantee a snug fit.

Manufacturers use precise methods to ensure the tubing meets size requirements. Special tools smooth and strengthen the tubing during production, while consistent processes ensure reliability across batches. Suppliers also test properties like strength and heat resistance to meet industry standards.

Evidence Description |

|---|

Studies show that how nitinol is made affects its strength. Testing samples helps you see if the tubing meets your needs. |

Careful methods make sure the tubing is the right size. |

Special tools keep the tubing smooth and strong. |

Consistent methods make tubing that works the same every time. |

Suppliers test things like strength and heat resistance to meet set standards. |

Rules like ASTM F2063 help keep nitinol materials consistent and high-quality. |

Following ASTM F2063 means testing to prove materials meet strict rules. |

Evaluating Material Properties and Shrink Ratios

Material properties and shrink ratios play a significant role in determining the suitability of customizable PET heat shrink tubing for specific applications. PET tubing offers excellent thermal stability, chemical resistance, and electrical insulation. However, variations in material properties can impact performance.

Studies in materials science highlight the importance of optimizing shrink ratios. For example:

The study by Cho et al. demonstrates a reduction in maximum residual stress of PET beverage bottles by 22%.

The shrinkage of PET beverage bottles was reduced by 25% through optimization of molding parameters such as temperature, pressure, and injection time.

Technical benchmarks also provide guidance for selecting suitable tubing. The maximum sizing should not exceed 15% above the diameter of the component, while the target shrink ratio is typically 1.1:1. Recovery capability of over 20% can be achieved by stabilizing the ends during heating.

Specification | Details |

|---|---|

Maximum Sizing | No larger than 15% above the maximum diameter of your part |

Target Shrink Ratio | 1.1:1 |

Recovery Capability | >20% achievable by drawing or stabilizing the ends as heated |

Considering Application-Specific Requirements

Different applications demand specific features from PET heat shrink tubing. For example, automotive applications require tubing that resists moisture, chemicals, and abrasion. Medical devices need tubing that remains clear and flexible after sterilization. Industrial equipment benefits from tubing that withstands corrosive substances and mechanical stress.

Polyethylene heat shrinkable tubing must meet the unique needs of each application. Matching the tubing’s expanded diameter to the largest part of the component ensures proper coverage. Ensuring the recovered diameter fits tightly around the smallest part guarantees effective insulation and protection.

Customizable PET heat shrink tubing provides tailored solutions for diverse industries. Its adaptability makes it suitable for applications requiring precision and reliability.

Ensuring Compliance with Industry Standards

Compliance with industry standards ensures that PET heat shrink tubing meets safety, quality, and performance benchmarks. Adhering to these standards is essential for industries like medical, automotive, and aerospace, where reliability and safety are critical. Manufacturers must follow established guidelines to guarantee that their products perform as intended under various conditions, including high-temperature resistance.

Several regulatory documents outline the requirements for PET heat shrink tubing, particularly in medical and industrial applications. These documents ensure that materials are safe, non-toxic, and environmentally friendly. The table below highlights key regulatory documents and their descriptions:

Regulatory Document | Description |

|---|---|

USP Class VI | Establishes biocompatibility testing for medical devices, requiring tests for systemic reactions. |

ISO 10993 | Defines biocompatibility standards for medical devices, categorizing body contact and exposure periods. |

FDA Title 21 | Regulates safety and effectiveness of medical devices, ensuring non-toxic materials are used. |

EU Regulation 1907/2006 | Addresses chemical substances to protect human health and the environment. |

In addition to regulatory documents, compliance standards play a vital role in ensuring the quality and safety of PET heat shrink tubing. These standards guide manufacturers in maintaining consistent production processes and meeting industry-specific requirements. The following table outlines some of the most widely recognized compliance standards:

Compliance Standard | Description |

|---|---|

ISO 13485 | Focuses on quality management systems for medical devices, ensuring product safety, quality, and performance. |

FDA Regulations | Ensures medical devices are safe and effective, guiding manufacturers in construction and electrical safety. |

RoHS Compliance | Ensures materials do not contain harmful substances that could compromise patient safety. |

By adhering to these standards, manufacturers can produce PET heat shrink tubing that meets the stringent demands of various industries. For example, ISO 13485 ensures that medical-grade tubing is manufactured under strict quality control, while RoHS compliance guarantees that materials are free from hazardous substances. These measures not only protect end-users but also enhance the reputation of manufacturers by demonstrating their commitment to quality and safety.

When selecting PET heat shrink tubing, buyers should verify that the product complies with relevant standards. This step ensures that the tubing will perform reliably in its intended application, whether it involves insulating electrical components or protecting medical devices. Consulting with suppliers who prioritize compliance can further streamline the selection process and provide peace of mind.

How to Test and Verify PET Heat Shrink Tubing

Testing for Proper Fit and Shrinkage

Proper fit and shrinkage are critical for ensuring PET heat shrink tubing performs as intended. Testing these aspects involves evaluating the tubing’s ability to conform tightly to components without compromising its structural integrity. Manufacturers often rely on standardized test methods to assess these properties under controlled conditions.

The following table highlights key test methods used to verify fit and shrinkage behavior:

Test Method | Description |

|---|---|

Evaluates linear dimensional changes of nonrigid thermoplastic sheeting or film at elevated temperatures. This is essential for understanding shrinkage behavior. | |

D2732-14(2020) | Measures unrestrained linear thermal shrinkage of plastic films and sheeting, directly applicable to PET heat shrink tubing. |

D2838-18 | Determines shrink tension and orientation release stress of plastic films, aiding in assessing fit and shrinkage performance. |

These tests provide valuable insights into how the tubing behaves when exposed to heat. For example, D2732-14(2020) ensures the tubing shrinks uniformly, while D2838-18 evaluates the stress levels during shrinkage. By adhering to these methods, manufacturers can guarantee consistent quality and performance.

Verifying Performance in Specific Conditions

PET heat shrink tubing must perform reliably in various environmental and operational conditions. Testing its performance involves exposing the tubing to factors such as temperature extremes, chemical exposure, and mechanical stress. For instance, thermal cycling tests simulate repeated heating and cooling to evaluate the tubing’s durability. Similarly, chemical resistance tests determine how well the tubing withstands exposure to oils, solvents, and corrosive substances.

In industrial applications, abrasion resistance tests are crucial. These tests measure the tubing’s ability to endure physical wear and tear. For electrical applications, dielectric strength tests ensure the tubing provides adequate insulation. Each of these evaluations confirms the tubing’s suitability for its intended use.

Tip: Always choose tubing that has been rigorously tested for the specific conditions it will encounter in your application. This ensures long-term reliability and safety.

Consulting Experts for Customizable Solutions

When standard PET heat shrink tubing does not meet unique application requirements, consulting industry experts can provide tailored solutions. Experts analyze the specific needs of the application, such as size constraints, environmental factors, and regulatory compliance. They then recommend customized tubing options that align with these requirements.

For example, in medical applications, experts may suggest tubing that meets USP Class VI standards for biocompatibility. In automotive settings, they might recommend tubing with enhanced resistance to moisture and chemicals. Collaborating with knowledgeable professionals ensures the selected tubing delivers optimal performance and meets all necessary specifications.

Note: Partnering with experienced suppliers can streamline the customization process, saving time and ensuring the highest quality standards.

Selecting the right PET heat shrink tubing involves understanding critical factors such as size, material properties, and application-specific requirements. These considerations ensure the tubing performs effectively and meets industry standards. Testing for fit, shrinkage, and performance under specific conditions further guarantees reliability.

Tip: Consulting experts can simplify the process and provide tailored solutions for unique applications.

Customizable PET heat shrink tubing offers flexibility for diverse industries. Readers should explore these options to find the best fit for their needs, ensuring durability, safety, and efficiency in their projects.

FAQ

What is the primary purpose of PET heat shrink tubing?

PET heat shrink tubing provides insulation and electrical protection for wires and components. It also offers mechanical protection against abrasion, moisture, and chemicals, ensuring enhanced safety and durability in various applications.

Can PET heat shrink tubing be used in medical equipment?

Yes, PET heat shrink tubing is suitable for medical equipment. Its biocompatibility and ability to withstand sterilization processes make it ideal for biocompatible applications, ensuring safety and performance in medical environments.

How does PET heat shrink tubing ensure quality and performance?

Manufacturers test PET heat shrink tubing for material quality and performance. These tests verify its insulation, shrinkage, and resistance to environmental factors, ensuring it meets industry standards for safety and reliability.

Is PET heat shrink tubing resistant to sterilization processes?

PET heat shrink tubing resists sterilization processes, maintaining its structural integrity and clarity. This makes it a preferred choice for medical applications requiring repeated sterilization without compromising performance.

Why is compliance important when selecting PET heat shrink tubing?

Compliance ensures PET heat shrink tubing meets safety and quality standards. Adhering to regulations guarantees its suitability for specific applications, such as medical equipment, where enhanced safety and reliability are critical.

See Also

A Comprehensive Approach To Selecting Proper Heat Shrink Tubing Size

Selecting The Ideal Ultra-Slim PET Heat Shrink Tubing For Your Needs

Finding The Most Suitable FEP Heat Shrink Tubing For Your Requirements

Navigating The Selection Of FEP Autoclavable Heat Shrink Tubing

Determining The Optimal FEP Biocompatible Heat Shrink Tubing For Your Uses