How to Choose the Best Laser Cutting Service for Your Needs

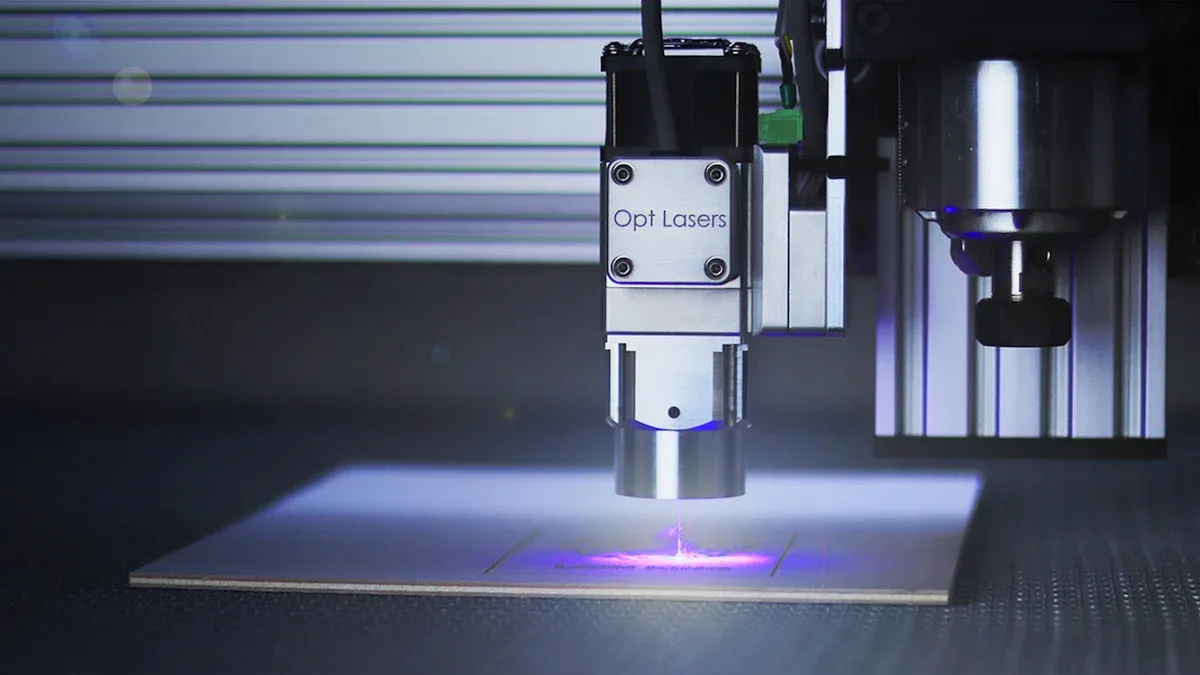

Choosing the best laser cutting service is very important. It can help your project succeed or fail. If you need detailed designs or perfect cuts, choose wisely. New technology helps make cuts accurate and clean. Skilled workers can handle tricky materials easily. For instance, companies with many years of experience often do better work. They know how to meet high-quality standards. Checking quality is also key to getting good results. By knowing what you need, you can find a service that is both precise and dependable.

Key Takeaways

Make sure the service works with your materials. This helps get the best results for your project.

Learn about CO2 and fiber laser machines. Pick the one that fits your material needs.

Check if the company has experience and good quality checks. Skilled workers do better work and manage tricky designs well.

Ask how fast they can finish and if they are flexible. A good service meets deadlines and adjusts to changes.

Find out if prices are clear. Ask for a full price list to avoid extra costs and stay on budget.

Key Factors to Consider

Material Compatibility

Making sure the service works with your materials.

When picking a laser cutting service, check if they can cut your materials. Not all machines can handle every material or thickness. For example, some are great for thin items like paper or plastic. Others work better with thick materials like steel or metal sheets. A skilled provider knows how to adjust settings for your material. This ensures precise cuts without causing damage.

Common materials and their cutting needs.

Laser cutting works on many materials. Popular choices include metals like steel, aluminum, and brass. Non-metals like wood, acrylic, and fabric are also common. Each material needs special care. For example, cutting metal needs more power for smooth edges. Cutting wood needs less power to avoid burns. Adjusting settings for each material type and thickness gives the best results.

Laser Cutting Technology

Comparing CO2 and fiber laser systems.

The laser system type affects your project. CO2 lasers are best for non-metals like wood and acrylic. They make smooth and precise cuts. Fiber lasers are better for metals, especially reflective ones like aluminum. They cut faster and are more efficient for big jobs. Knowing the strengths of each helps you pick the right one.

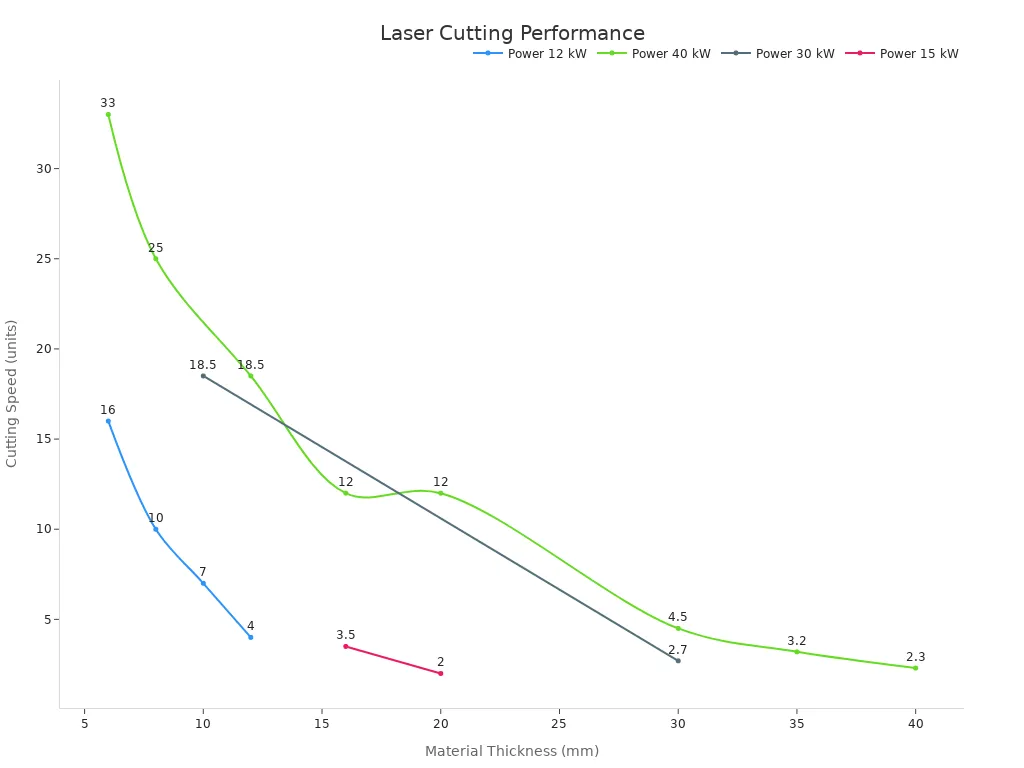

How power levels affect cutting.

Laser power is important for cutting well. High power cuts thick materials better. Low power works for thin materials. For example, a 40 kW laser cuts 20 mm steel faster than a 12 kW laser. Here’s a quick look at cutting speeds for different powers:

Laser Power (kW) | Material Thickness (mm) | Cutting Speed (units) |

|---|---|---|

12 | 6 | 16 |

40 | 6 | 33 |

12 | 20 | 2 |

40 | 20 | 12 |

Expertise and Quality Assurance

Why experience matters in laser cutting.

Experience is key when choosing a laser cutting company. A skilled company can handle tricky designs and give great results. For example, AccuPath is known for cutting Nitinol Tubing. Their years of work ensure top-quality results, even for hard projects.

How quality checks improve results.

Good quality checks make better products. Companies with strict rules give clean cuts and smooth edges. This reduces extra work after cutting. For instance, fiber lasers are very accurate. They can cut within tiny tolerances, making them perfect for industries needing high precision.

Turnaround Time and Flexibility

Checking if a provider can meet deadlines.

Timing is very important for projects. If a laser cutting service is late, it can mess up your plans. Always ask about their delivery time before hiring them. Do they work quickly? Can they handle your project size without delays? A good company should finish on time, whether it’s a small sample or a big order.

Here’s a simple guide to what to check:

Aspect | Details |

|---|---|

Turnaround Time | Check if the provider can meet your deadlines. |

Efficiency | Make sure they have fast processes to deliver on time. |

For example, AccuPath is great at finishing jobs quickly and accurately. They are skilled at cutting Nitinol Tubing, even for hard projects.

Why flexibility matters for changing plans.

Projects don’t always go as planned. Sometimes, you need to change designs or rush an order. Flexibility is very important in these cases. A good laser cutting service should adjust to your needs. Ask if they can handle quick orders or changes without lowering quality.

Companies like AE Oscroft show how being flexible helps. Their tools can handle small samples or big orders. This lets them adjust to different needs.

Aspect | Details |

|---|---|

Flexibility | Find providers who can handle quick orders or changes. |

Responsiveness | Modern tools should support different project needs. |

Picking a flexible company keeps your project on track. Providers like AccuPath can adapt while giving excellent results.

Types of Laser Cutting Services

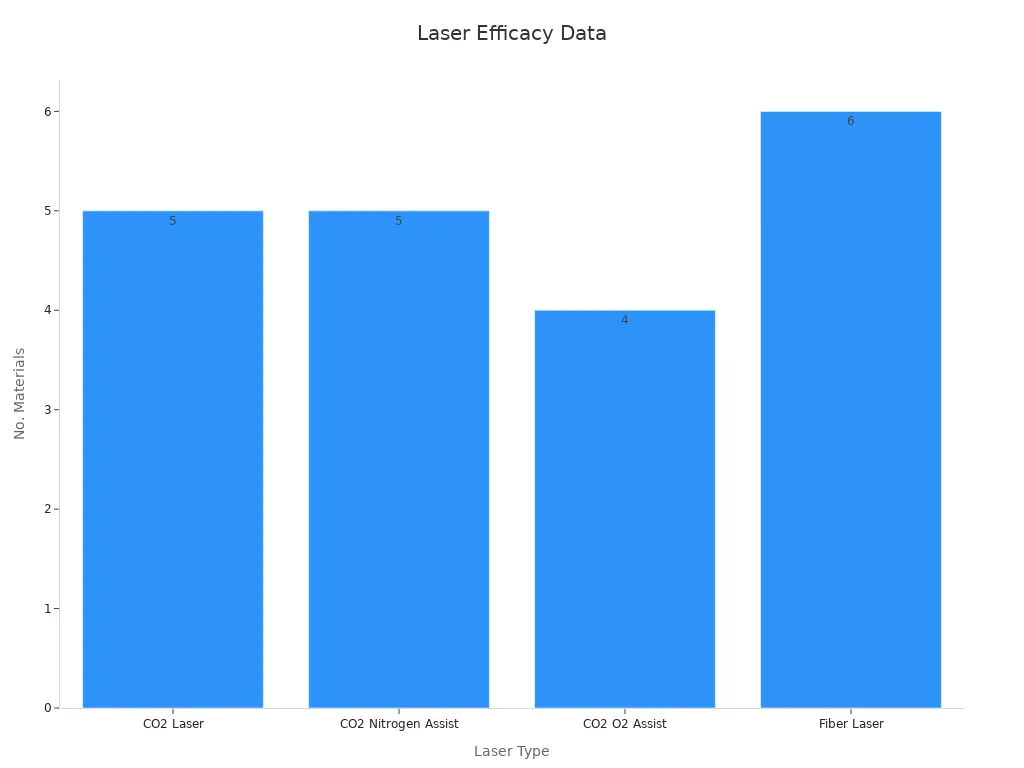

CO2 Laser Cutting

Best uses and benefits of CO2 laser cutting.

CO2 laser cutting works well for non-metals like wood and paper. It can also cut metals like aluminum and steel with gas help. This method makes smooth edges and detailed designs. It’s great for making signs, furniture, and packaging.

Here’s why CO2 lasers are useful:

They cut thin materials with high accuracy.

They work on many materials, even glass and stone.

They don’t touch the material, so it stays clean.

For example, CO2 lasers are great for cutting metal sheets for decorations or making patterns on wood.

Downsides of using CO2 lasers.

CO2 lasers are flexible but have limits. They use more energy than fiber lasers. They also don’t work well with shiny metals like copper. Cutting thick materials is slower, which can delay big projects.

Material Type | CO2 Laser | CO2 Nitrogen Assist | CO2 O2 Assist |

|---|---|---|---|

Plastic | ✓ | ||

Glass | ✓ | ||

Wood | ✓ | ||

Aluminum | ✓ | ✓ |

Fiber Laser Cutting

Best uses for fiber laser cutting.

Fiber lasers are great for cutting metals, especially shiny ones like brass. They also cut thin steel quickly and accurately. Industries like cars and airplanes use fiber lasers for their speed and precision.

Why fiber lasers are good for shiny metals.

Fiber lasers are perfect for reflective metals. Unlike CO2 lasers, they cut these without problems. They use less energy, saving money over time. They also cut thin materials faster, improving efficiency.

Aspect | Fiber Laser Cutting | CO₂ Laser Cutting |

|---|---|---|

Cutting Speed (1mm Steel) | 3 times faster than CO₂ | Slower |

Energy Consumption | Lower (3 kW fiber uses 1/3 of 4 kW CO₂) | Higher |

Material Compatibility | Can cut reflective materials | Limited with reflective materials |

Specialized Techniques

Special laser cutting methods overview.

Sometimes regular laser cutting doesn’t work for special projects. Advanced methods like precision cutting or hybrid systems can handle tricky designs or materials. These are great for industries needing exact results, like medical tools.

When to pick special techniques for tough projects.

If your project needs complex designs or materials like Nitinol Tubing, choose special methods. Companies like AccuPath are experts in this. They deliver top-quality results for even the hardest jobs.

Evaluating Laser Cutting Service Providers

Equipment and Technology

Why modern laser tools are important.

The tools a company uses affect your project’s success. New laser machines work faster and cut more precisely. They can handle tricky designs and tough materials easily. For example, advanced lasers cut metals quickly while keeping edges smooth. Old machines might not meet your needs or expectations.

Questions to ask about their tools.

Always ask about the company’s equipment. Do they use CO2 or fiber lasers? What is the power of their lasers? These details show what they can do. For instance, AccuPath uses top-notch tools for cutting hard materials like Nitinol Tubing. Knowing this helps you pick the right provider.

Customer Service and Communication

Why good communication matters.

Clear communication keeps your project on track. A good company listens to your needs and gives updates. Misunderstandings can cause delays or mistakes. Choose a provider who values your input and keeps you informed.

How to check their customer service.

Test how quickly they respond to your questions. Are they willing to discuss changes or problems? A company with great customer service will adjust to your needs. For example, AccuPath is known for being flexible and helpful, ensuring projects run smoothly.

Reviews and Proven Track Record

Why reviews are helpful.

Customer reviews tell you if a company is reliable. Look for comments about speed, precision, and quality. Positive reviews show they care about doing good work. Don’t be afraid to ask for examples of their past projects.

Why experience is important.

Experienced companies know how to handle different materials and designs. They can also fix problems quickly. For example, AccuPath’s years of experience make them a trusted choice for industries needing precise work, like medical tools or airplanes.

Cost and Value Considerations

Balancing Budget and Quality

Why the cheapest choice might not be the best.

Picking the cheapest laser cutting service can seem smart. But it may lead to problems like bad cuts or delays. Low-cost services might not have good tools or skilled workers. This can cause mistakes or damage to materials. For example, AccuPath’s skill in cutting Nitinol Tubing ensures accuracy. Cheaper services might not match this quality. Spending more now can prevent costly errors later.

Why quality services are worth it over time.

Paying for better services often saves money later. Good laser cutting reduces waste, speeds up work, and avoids fixing mistakes. This saves time and money during your project. Companies like AccuPath use advanced tools to give steady, high-quality results. This keeps your project on schedule and within budget.

Transparent Pricing

Watching out for hidden fees in services.

Some companies offer low prices but add extra fees later. These can include setup, material handling, or finishing costs. These hidden charges can increase your total cost. Always ask for a full price list. This helps you compare services fairly and avoid surprises.

Why clear pricing is important.

Clear pricing helps you trust the company and plan better. Look for companies that give honest quotes without hidden fees. For example, AccuPath is known for upfront pricing. You’ll know exactly what you’re paying for. This makes it easier to balance cost and quality.

Cost-Effective Solutions

How to save money while keeping quality.

Saving money doesn’t mean losing quality. For example, using smart nesting techniques reduces waste and saves money. Advanced laser systems, like those at AccuPath, make clean and precise cuts. This gives great results without overspending.

Why quality saves money in the long run.

Quality services cost more at first but save money later. Here’s a comparison:

Aspect | Tube Laser Cutting | Traditional Methods |

|---|---|---|

Initial Investment | Costs more upfront | Costs less upfront |

Production Time | Faster production | Slower production |

Material Waste | Less waste | More waste |

Labor Costs | Lower labor costs | Higher labor costs |

Maintenance Costs | Lower maintenance | Higher maintenance |

Risk of Human Error | Lower with automation | Higher with manual work |

As shown, advanced laser cutting, like AccuPath’s, saves money on labor, materials, and repairs. Their skill in cutting Nitinol Tubing ensures precision without extra costs.

Picking the right laser cutting service is very important. It can decide if your project succeeds or fails. Think about material compatibility, cutting technology, skill, and cost. These help you get accurate results without wasting time or money.

🛠 Pro Tip: Check a company’s experience and quality checks. Experts like AccuPath, skilled in cutting Nitinol Tubing, offer great precision and dependability.

Understand what your project needs. Spend time researching and asking questions. This way, you’ll find a service that fits your needs and ensures success.

FAQ

What matters most when picking a laser cutting service?

Focus on material compatibility. Not all services cut every material. For example, AccuPath is skilled at cutting Nitinol Tubing. This material needs precision and experience. Always check if the company knows your material.

🛠 Pro Tip: Look at their past work to see if they fit your needs.

How can I tell if a company uses modern laser tools?

Ask about their machines. Companies with advanced tools, like fiber lasers, give better results. For instance, AccuPath uses top systems to cut reflective metals and tricky designs. This ensures great quality for your project.

Can laser cutting services handle sudden changes?

Yes, but it depends on the company. Some, like AccuPath, are great at adjusting to changes. They can handle quick design edits or rush jobs. Their team works fast without lowering quality.

Why is AccuPath good for cutting Nitinol Tubing?

AccuPath has lots of experience with Nitinol Tubing. Their skilled team and advanced tools make precise cuts. They’re a trusted choice for medical and aerospace projects needing accuracy.

✅ Did You Know? Nitinol Tubing is tricky to cut because of its special properties. AccuPath’s skill makes them a leader in this area.

Are there extra fees in laser cutting services?

Some companies add costs for setup or finishing. Always ask for a full price list. AccuPath gives clear pricing, so you know what you’ll pay. This helps you plan your budget better.

💡 Tip: Compare prices from different companies to get the best deal without losing quality.