China Nitinol tubing factory for export: fast, flexible, friendly

You want fast results, flexible solutions, and friendly support. A china nitinol tubing factory for export gives you all three. China leads the world in advanced manufacturing and strong supply chains. You get high-quality tubing at a lower cost. Many buyers choose a china nitinol tubing factory for export because they trust china’s commitment to reliable export service and customer satisfaction.

Key Takeaways

Chinese nitinol tubing factories deliver fast production and efficient shipping, ensuring you get your orders quickly and on time.

These factories offer flexible options with custom sizes, shapes, and order quantities to fit your specific needs and help you grow.

Strong communication and after-sales support keep you informed and supported throughout your project, reducing risks and delays.

You receive high-quality nitinol tubing that meets strict medical standards and comes with trusted certifications for safety and reliability.

Competitive pricing and easy global sourcing from China help you save money while accessing top suppliers and reliable service.

Speed

Fast Production

You want your nitinol tubing fast. Chinese factories make this possible. They use advanced machines and skilled workers. You get your nitinol products quickly because these factories run around the clock. They do not waste time. You can place an order and see it move into production almost right away. Many factories keep raw materials ready, so they can start making your nitinol tubing as soon as you confirm your order.

Tip: If you need a special size or shape, Chinese factories can adjust their machines fast. You do not have to wait weeks for setup. This flexibility means you get your nitinol tubing on your schedule, not theirs.

Efficient Delivery

You need your nitinol tubing delivered on time. Chinese factories understand this. They have built a strong supply chain of nickel titanium tube that connects suppliers, manufacturers, and shippers. This network keeps your orders moving smoothly from the factory to your door.

Here is why you can trust Chinese factories for fast export and delivery:

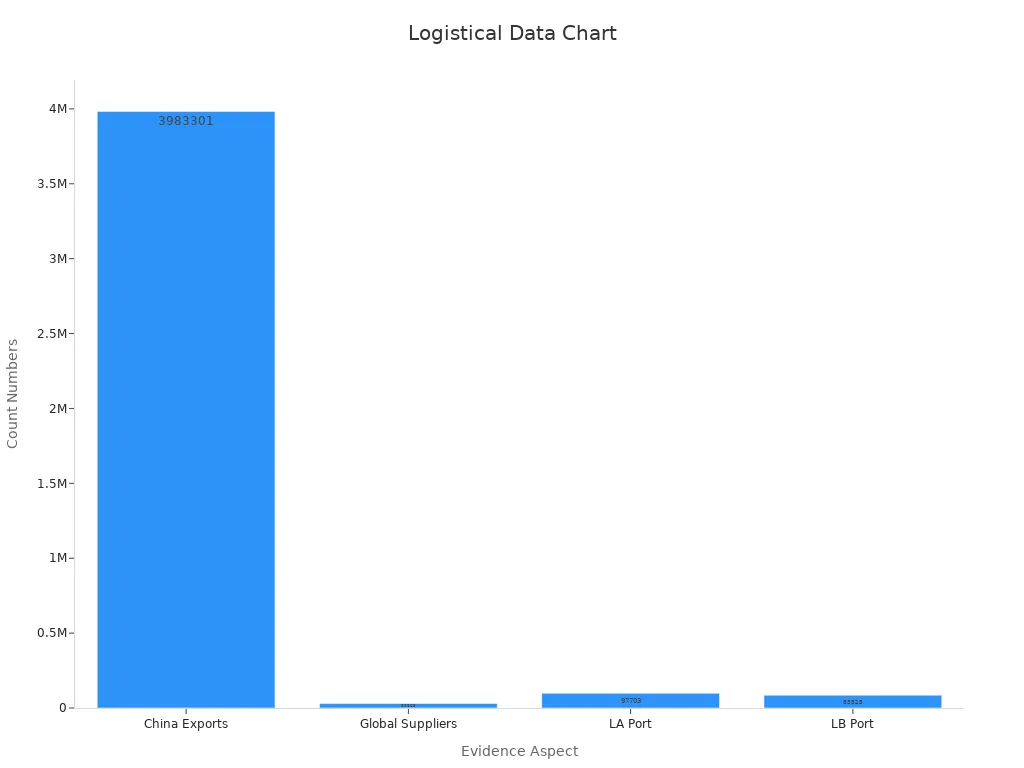

Evidence Aspect | Details |

|---|---|

Export Volume | China leads tubing exports with nearly 4 million shipments (3,983,301 export counts), indicating high shipment volume and capacity. |

Supplier Network | Over 30,365 active global tubing suppliers, including many in China, showing a broad and reliable supplier base. |

Shipment Data Fields | Detailed shipment records include dates, quantities, ports of origin/destination, and supplier/buyer info, reflecting transparency and organization. |

Major Import Ports in US | Top US ports like Los Angeles (97,703 shipments) and Long Beach (85,525 shipments) handle large volumes from China, indicating streamlined logistics. |

Supply Chain Optimization Tools | Advanced filters and analytics on Volza’s platform help optimize supply chain efficiency, supplier reliability, and cost-effectiveness. |

You benefit from this organized system. Your nitinol tubing moves quickly through customs and shipping. You can track your order at every step. Volza’s platform gives you access to shipment details and helps you connect with top suppliers. This means you get reliable updates and fewer delays.

Choose a Chinese nitinol tubing factory for export. You get speed, reliability, and peace of mind.

Flexibility

Custom Orders

You want nitinol tubing that fits your exact needs. Chinese factories give you this power. You can order nitinol in many forms—wire, tubing, sheet, or powder. Each form works for different uses, especially in the cardiovascular field. You get to choose the size, shape, and even the finish. Factories use advanced tools like laser cutting, electropolishing, and shape setting. These methods help you get superelastic nitinol alloys with the right properties for your project.

If you need tight tolerances for medical devices, you can trust Chinese factories. They control the nickel content and temperature with great care. This means your nitinol meets strict standards for cardiovascular implants and other sensitive uses. You can ask for custom stents, guidewires, or other parts. Factories use 3D printing and micromachining to create complex shapes. You get rapid prototypes and patient-specific designs. This flexibility helps you stay ahead in the fast-changing cardiovascular market.

Note: Superelastic nitinol alloys keep their shape and strength, even after bending. This makes them perfect for cardiovascular devices that need to move and flex inside the body.

Order Size Options

You do not have to worry about minimum order sizes. Chinese factories work with both small and large orders. You can start with a small batch to test your design. If you like the results, you can scale up fast. This approach saves you money and reduces risk. You get the same high quality for every order, no matter the size.

Factories adapt to your needs. You can order superelastic nitinol alloys for a single cardiovascular device or for mass production. You get fast turnaround and reliable delivery. This flexibility lets you respond quickly to market changes or new customer requests.

Order a few custom nitinol tubes for a new cardiovascular device.

Scale up to thousands of superelastic nitinol alloys for a big launch.

Change your order size as your business grows.

You stay in control. Chinese factories make it easy to get the nitinol products you need, when you need them.

Service

Communication

You deserve clear answers and fast responses when you order nitinol tubing. Chinese factories know this. They invest in strong communication channels to help you every step of the way. You get support from bilingual staff who understand your needs. Translation services and cultural training help bridge any gaps. This means you can ask questions about superelastic nitinol alloys and get answers right away.

Factories use real-time monitoring and scorecards to track how quickly they respond to your requests. They measure how well they answer your questions about nitinol, superelastic nitinol alloys, and cardiovascular applications. You see their willingness to help and share information. Regular reviews and customer surveys keep their service sharp.

Communication effectiveness and flexibility set Chinese suppliers apart.

You get updates on your order status, delivery times, and product details.

Factories act on your feedback to improve their service.

Tip: If you ever face a language barrier, you can rely on translation support. This keeps your project on track and helps you avoid costly mistakes with superelastic nitinol alloys.

After-Sales Support

Your relationship with a Chinese nitinol tubing factory does not end after delivery. You get after-sales support that helps you succeed. If you have questions about superelastic nitinol alloys or need help with a cardiovascular device, you can reach out anytime. Factories track product quality, delivery times, and compliance with standards. They use this data to solve problems fast.

You can expect:

Support Feature | What You Get |

|---|---|

Quick Response | Fast help with any issues or questions |

Technical Guidance | Expert advice on using superelastic nitinol alloys |

Replacement & Returns | Easy process if you need to exchange products |

Continuous Improvement | Factories use your feedback to get better |

You stay in control. Chinese factories want you to succeed with nitinol and superelastic nitinol alloys. They work hard to earn your trust and keep you coming back for your next cardiovascular project.

China Nitinol Tubing Factory for Export

Nitinol Quality

You want the best for your cardiovascular projects. A china nitinol tubing factory for export gives you that edge. You get nitinol that meets strict standards for strength, flexibility, and shape memory. Superelastic nitinol alloys from these factories keep their shape even after bending. This makes them perfect for cardiovascular devices that need to move inside the body. You can trust the quality because factories in china use advanced testing for every batch. They check the nickel content, temperature response, and surface finish. You see the results in every piece of nitinol you order.

Superelastic nitinol alloys help you create devices that last longer and perform better. You get tubing that resists fatigue and corrosion. This means your cardiovascular products stay safe and reliable. When you choose a china nitinol tubing factory for export, you get consistent quality every time. Factories use modern machines and skilled workers to make sure your nitinol meets your needs. You can ask for custom shapes or sizes, and the factory will deliver exactly what you want. Superelastic nitinol alloys give you the confidence to innovate in the cardiovascular field.

Certifications

You need proof that your nitinol meets global standards. A china nitinol tubing factory for export provides that assurance. Leading factories, such as Baoji Highstar Titanium Metal Co., Ltd, show their commitment to quality with recognized certifications. You can look for these important marks:

ISO 9001: Shows the factory uses a strong quality management system.

RoHS: Confirms the nitinol is safe for the environment and free from harmful substances.

CE: Proves the tubing meets European health, safety, and environmental rules.

ASTM standards: Ensures the nitinol and superelastic nitinol alloys follow strict material and testing guidelines.

These certifications help you trust the nitinol you buy. You know your cardiovascular devices will meet the demands of doctors and patients worldwide. Superelastic nitinol alloys from china give you a clear advantage in the global market. When you choose a china nitinol tubing factory for export, you get quality, safety, and peace of mind.

Cost & Sourcing

Competitive Pricing

You want to stay ahead in the nickel titanium tube market. Chinese factories help you do that with unbeatable prices. Lower labor costs and efficient material sourcing give you a real advantage. You pay less for high-quality tubing. This means you can offer better prices to your customers and win more business.

Factories in China use advanced technology to cut waste and boost productivity. You see these savings in your final quote. Many suppliers offer bulk discounts, so you save even more when you scale up. You get the best value for your money in the nickel titanium tube market.

Tip: Ask for a detailed price breakdown. You will see how Chinese suppliers keep costs low without cutting corners on quality.

Global Procurement

You need easy access to suppliers in the nickel titanium tube market. China makes global procurement simple. You can find hundreds of trusted factories on platforms like Alibaba. These platforms let you compare prices, check reviews, and contact suppliers directly.

Here is how you benefit from global sourcing in China:

Wide selection of nickel titanium tube market suppliers

Fast quotes and clear communication

Secure payment and buyer protection

Flexible shipping options to your country

Sourcing Platform | Key Features |

|---|---|

Alibaba | Verified suppliers, trade assurance, easy comparison |

Made-in-China | Detailed product listings, direct messaging |

Global Sources | International focus, quality checks |

You control the process from start to finish. You choose the best supplier for your needs in the nickel titanium tube market. You get fast delivery and reliable service every time.

You want to lead in the nickel titanium tube market. Chinese factories give you speed, flexibility, and service. You get tubing with precise accuracy and strong testing. Factories use automation and advanced shaping for the highest growth potential. They meet strict medical standards, so your products fit the cardiovascular devices market. Surface treatments make your tubing last longer. Choose Chinese suppliers to stay ahead in the nickel titanium tube market and deliver quality every time.

FAQ

What is Nitinol tubing used for?

You use Nitinol tubing in medical devices, especially for cardiovascular implants. It works well for stents, guidewires, and surgical tools. Its superelasticity and shape memory help your products perform better and last longer.

How fast can I get my order from a Chinese factory?

You get your order quickly. Most factories start production right after you confirm. Shipping often takes just a few days to a few weeks, depending on your location and order size.

Can I order custom sizes or shapes?

Yes! You choose the exact size, shape, and finish you need. Chinese factories use advanced machines to create custom tubing for your project. You get perfect results for every order.

Are Chinese Nitinol tubing factories certified?

Leading factories hold ISO 9001, CE, and RoHS certifications. You get tubing that meets strict global standards. Always ask your supplier for proof of certification before you buy.

See Also

The Process Behind Manufacturing Nitinol Tubing For Medicine

Choosing The Right Nitinol Tubing Supplier For Your Needs

Finding The Most Cost-Effective 2mm Nitinol Tubing Supplier