Perfect Protection: PET Heat Shrink Tubes

Chemical resistant PET heat shrink tube is strong and resists chemicals well. It is used in many industries because it works reliably.

The global market for chemical resistant PET heat shrink tube may grow from $650 million in 2024 to $960 million by 2032. This shows more people need it.

The electrical and electronics industry uses 38% of chemical resistant PET heat shrink tube. This proves it is important for protecting wires.

The car industry expects a 6.2% yearly growth. This is because cars need tough insulation for their wiring, which is provided by chemical resistant PET heat shrink tube.

In healthcare, medical devices may grow 7.5% each year. This shows chemical resistant PET heat shrink tube is useful for safe, chemical-resistant tools.

These facts show chemical resistant PET heat shrink tube is flexible and handles tough conditions. It is needed in industries like aerospace and healthcare.

Key Takeaways

PET heat shrink tubing is tough and resists chemicals. It works well in industries like cars and healthcare.

The global market for PET tubing is growing fast. This shows more people need its protective features.

This tubing gives great electrical insulation, handling over 4,000 V/mil. It keeps electrical systems safe.

PET tubing is light and bends easily. It’s simple to use and lowers vehicle weight, helping save fuel.

Medical PET tubing follows strict safety rules. It protects medical tools and keeps patients safe.

Understanding Chemical Resistant PET Heat Shrink Tube

Why is PET Chemically Resistant?

PET heat shrink tubing resists chemicals because of its special structure. Its polymer chains are tightly packed, forming a strong barrier. This stops chemicals like oils, acids, and solvents from breaking it down. PET also repels water, which helps it last longer in tough conditions.

Studies show how the environment affects PET's resistance. For example, sunlight, heat, and humidity can change its performance. High heat makes the chains move more, causing faster wear. Humidity can lead to water damage and oxidation. Even with these issues, PET stays strong and works well in most situations.

Important Features of PET Heat Shrink Tubing

PET heat shrink tubing has many features that make it useful. It provides great electrical insulation with a strength over 4,000 V/mil. It works in temperatures from -196°C to 135°C for long use and up to 200°C for short times. Its melting point is 235°C, so it handles high heat.

Here’s a table of PET's key features:

Feature | Value |

|---|---|

Electrical Strength | > 4,000 V/mil |

Long-term Temperature Range | -196°C to 135°C |

Short-term Temperature Range | Up to 200°C |

Melting Point | 235°C |

Shrinkage Capability | Up to 50% or more |

PET tubing meets strict safety rules like ISO 10993-5 for toxicity and ISO 10993-10 for irritation. These prove it is safe and reliable, especially for medical tools.

How PET Tubing Works in Tough Conditions

PET heat shrink tubing is great for harsh environments. It resists chemicals, sunlight, and water damage. Its strong design stops corrosion and wear, even with harsh substances. For example, in cars, it protects wires from oil and fuel. In factories, it shields parts from harmful chemicals.

It also works in extreme temperatures. PET tubing stays flexible in freezing cold at -196°C. It also stays strong in heat up to 200°C. This makes it useful in many fields, like aerospace and healthcare.

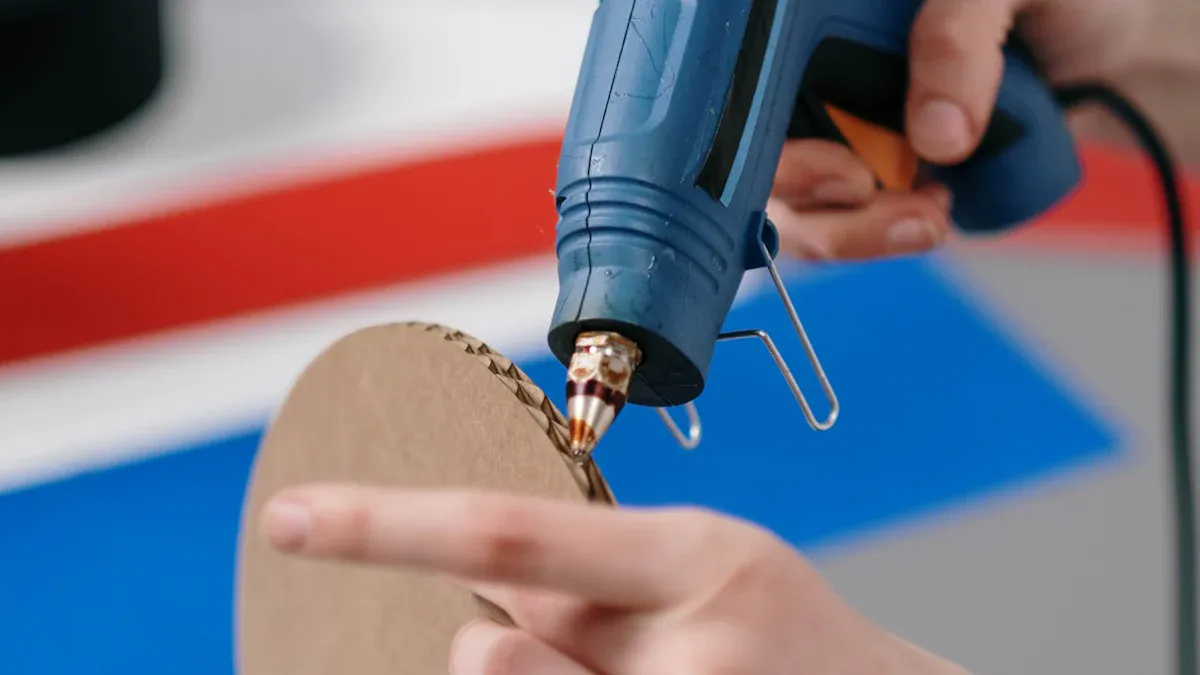

Tip: Use heat around 150°C (302°F) for the best shrinkage. This ensures a tight fit and strong protection.

Applications of PET Heat Shrink Tubing

Industrial and Automotive Applications

PET heat shrink tubing is important in factories and cars. It protects wires, cables, and parts from chemicals like oil and fuel. In cars, it keeps wires safe from heat and damage, helping them last longer. Factories use it to cover machine parts, stopping rust and wear from chemicals.

This tubing is light and flexible, making it easy to use. It also reduces car weight, which helps save fuel. It works in very cold places at -196°C and very hot ones up to 200°C. This makes it great for tough jobs in industries.

Note: PET heat shrink tubing blocks UV rays, making it perfect for outdoor use in factories and cars.

Electrical and Electronic Uses

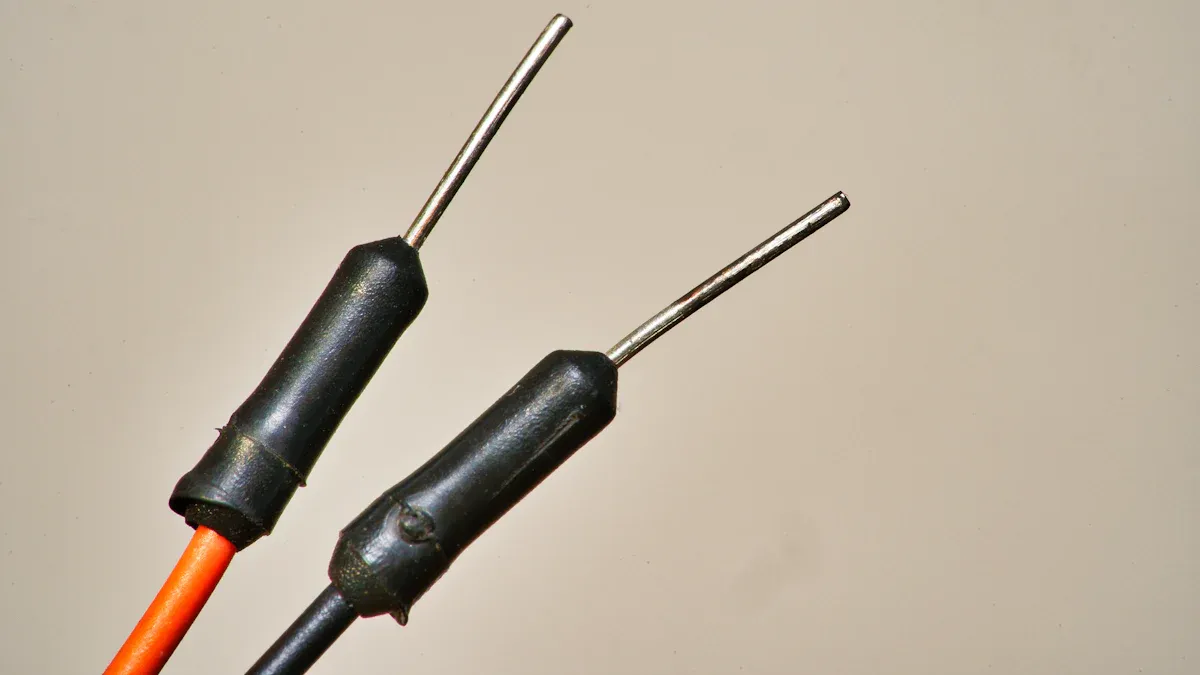

PET heat shrink tubing is great for electrical systems. It stops short circuits and keeps parts safe from water, dust, and chemicals. Engineers use it to group wires, cover connectors, and protect circuit boards, ensuring they work well for a long time.

Here’s a table of its key features:

Property | Specification Requirement | Test Method |

|---|---|---|

Tensile strength | ASTM D2671 | |

Shrink ratio | 2:1 | N/A |

Dielectric Strength | > 4,000 V/mil | N/A |

Long-term Temperature | -196°C to 135°C | N/A |

Short-term Temperature | Up to 200°C | N/A |

These features show it works well in electrical tasks. Its insulation strength of over 4,000 V/mil keeps electricity safe. The 2:1 shrink ratio fits it tightly around wires. It also lasts a long time, making it a good choice for electronics.

Medical-Grade PET Heat Shrink Tubing in Healthcare

Medical-grade PET heat shrink tubing is very useful in healthcare. It resists chemicals and is safe for medical tools like catheters and surgical devices. It meets strict rules like ISO 10993-5 for safety and ISO 10993-10 for irritation, keeping patients safe.

Doctors trust this tubing because it handles cleaning with heat and strong chemicals. It bends easily to fit complex tools, making it perfect for detailed medical devices.

Medical tools need to be precise and strong. PET heat shrink tubing protects them from water, UV rays, and chemicals. Its light design makes tools easier to use, and its strength helps them last longer. As healthcare grows, more PET heat shrink tubing will be needed for new medical technology.

Tip: Choose medical-grade PET heat shrink tubing that meets safety and cleaning standards.

Benefits of PET Heat Shrink Tubing

Strong and Long-Lasting

PET heat shrink tubing is tough and lasts a long time. It works well in extreme conditions without losing its strength. For example, it stays strong in temperatures from -196°C to 135°C for long periods. Even short-term heat up to 200°C doesn’t damage it. This makes it perfect for industries like cars and airplanes that need strong insulation.

Its electrical strength is over 4,000 V/mil, making it safe for electrical uses. It also meets ISO 10993 standards, proving it’s safe for medical tools. Tests show it resists wear and damage, even in harsh chemical environments. These features lower repair costs and make it last longer.

Attribute | Value |

|---|---|

Dielectric Strength | Over 4,000 V/mil |

Long-term Temperature Range | -196°C to 135°C |

Short-term Exposure Temperature | Up to 200°C |

Melting Point | 235°C |

Biocompatibility Standards | ISO 10993 |

Sterilization Resistance | Stays strong after cleaning |

Chemical Resistance | Resists oils and cleaning agents |

Protects Against Damage from Sun, Water, and Chemicals

PET heat shrink tubing is great for outdoor and factory use. It blocks UV rays, stopping damage from sunlight. This is helpful for outdoor LED lights, where it protects wires from the weather.

It also keeps out water and stops rust, working well in wet or chemical-filled places. For example, it protects industrial LED systems from water, sunlight, and temperature changes. Its anti-aging design means it lasts longer, so you don’t need to replace it often.

Note: PET heat shrink tubing is perfect for tough jobs in harsh environments.

Lightweight, Bendable, and Easy to Install

PET heat shrink tubing is light and flexible, making it easy to use. It bends to fit tricky shapes, so it’s great for wiring in medical tools and car parts. Its 2:1 shrink ratio ensures it fits tightly around wires for strong protection.

Its lightweight design helps reduce the weight of cars and planes. This improves fuel efficiency and lowers costs. It’s also quick to install, saving time for engineers and workers.

Application | Benefit |

|---|---|

LED Strip Lights | Covers wires for safe use. |

Outdoor LED Installations | |

Industrial LED Systems | Insulates wires in tough environments. |

With its flexibility, light weight, and ease of use, PET heat shrink tubing works well in many industries.

Comparing PET Heat Shrink Tubing to Other Materials

PET vs. Polyolefin: Chemical Resistance and Strength

PET tubing resists chemicals better than polyolefin tubing. Its strong structure stops damage from oils and solvents. This makes it great for medical tools and factory machines. PET tubing stays strong after cleaning many times. Polyolefin tubing can bend or weaken in tough conditions. It is less useful where high strength is needed.

PET tubing is also safer for medical use. It meets strict rules for tools like catheters and surgical devices. Polyolefin tubing works well but isn’t as strong or safe as PET in hard environments.

PET vs. PVC: Durability and Environmental Impact

PET tubing lasts longer and is better for the planet than PVC. PVC pipes can last over 100 years because they resist rust. But PET tubing handles sunlight and heat better, making it good for outdoor use. PET is light and bends easily, which helps parts stay strong.

PET tubing is made in a cleaner way than PVC. PVC production creates more pollution. PET also stops bacteria from growing, making it safer for food and medical uses.

Why PET Heat Shrink Tubing is the Best Choice for Chemical Resistance

PET tubing is the top choice for resisting chemicals. It doesn’t break down from oils, acids, or solvents. It stays strong after cleaning and meets safety rules for healthcare. PET also blocks sunlight, water, and heat, making it useful in many industries.

Car, airplane, and medical companies trust PET tubing for its strength and durability. It’s light, easy to install, and made in an eco-friendly way. These features make PET tubing the best option for tough jobs.

PET heat shrink tubing is strong, durable, and resists chemicals well. It works in tough conditions, making it useful in many industries. It protects car wires and keeps medical tools safe and reliable.

Key Insight: PET tubing lasts long and is eco-friendly. Its light weight and flexibility make it easy to use and lower repair costs.

Using PET heat shrink tubing gives reliable results in hard situations. Its strength and versatility make it important for industries and healthcare today.

FAQ

What is PET heat shrink tubing made of?

PET heat shrink tubing is made from polyethylene terephthalate, a strong material. Its tightly packed structure makes it tough and resistant to chemicals. This helps it work well in hard environments.

How does PET heat shrink tubing protect wires?

PET tubing covers wires with a tight, protective layer. It blocks moisture, chemicals, and sunlight, keeping wires safe. This ensures they last longer, even in tough conditions.

Tip: Use a heat gun carefully to shrink the tubing evenly.

Can PET heat shrink tubing be used outdoors?

Yes, PET heat shrink tubing is great for outdoor use. It resists sunlight, water, and temperature changes. This makes it perfect for outdoor jobs like LED lights and car wiring.

Is PET heat shrink tubing safe for medical devices?

Yes, medical-grade PET tubing follows strict safety rules like ISO 10993. It handles cleaning and is safe for tools like catheters and surgical devices.

What industries benefit most from PET heat shrink tubing?

Industries like cars, healthcare, and electronics use it the most. Its strength, flexibility, and chemical resistance protect wires, cables, and delicate parts.

Key Insight: PET heat shrink tubing works well in many environments, offering strong protection for different industries.