How to Select Nitinol Tubing for Medical Devices in 2025

When you pick nitinol tubing for a medical device, you need to think about how well it works and if it is safe. Make sure the Af temperature matches body temperature. This helps your device work right in the body. Fatigue resistance and surface finish are important. They help the device last longer and keep patients safe. The quality of the supplier is important too. Rules are different in each country. The nitinol tubing market may reach almost $2 billion in 2025. This is because people want better devices. Always think about what the device will do, its size, and the rules you must follow before you buy nitinol tubing.

Key Takeaways

Pick nitinol tubing with an Af temperature just under body temperature. This helps it work well inside the body.

Find tubing that can handle lots of bending and moving. This makes sure your device will last a long time.

Choose tubing with a smooth and clean surface. This stops rust, lowers risks, and helps your device last longer.

Work with trusted suppliers who give you quality papers and help. This way, you get tubing you can count on for your needs.

Think about special choices like laser cutting and coatings. These can make your device work better and feel nicer for patients.

Nitinol Tubing Properties

Shape Memory & Superelasticity

When you pick shape memory alloy tubing, you get two special features. The shape memory effect lets the tubing go back to its first shape when it gets warm enough. This is important for devices that need to change inside the body. Superelasticity means the tubing can bend or stretch and still return to normal. You see this in things like self-expanding stents and guidewires. Shape memory effect lets the tubing stretch up to 8%, which is much more than stainless steel. This makes it good for small surgeries and helps the device work well in moving places. Shape memory alloy tubing also soaks up vibration and does not kink easily. That is why it is a great pick for new medical devices.

Tip: Shape memory effect and superelasticity help niti tubing work well in devices that need to bend and return to shape inside the body.

Af Temperature Selection

You need to pick the right Af temperature for your device. Af temperature is when the tubing finishes changing back to its strong shape. Most medical devices need the Af temperature just under body temperature. This makes sure the shape memory effect and superelasticity work at 37°C. Makers set the Af temperature by changing the nickel and titanium mix and using special heat. Tests like Bend Free Recovery and Differential Scanning Calorimetry check if the Af temperature is right. The table below gives important details:

Aspect | Details |

|---|---|

Typical Af Temperature Range | 0 to 20°C |

Purpose | Superelasticity at body temperature |

Control Factors | Alloy composition, heat treatment |

Standards | ASTM F2082, ASTM F2004 |

Fatigue Resistance

Fatigue resistance and strength are very important for devices that bend or move a lot. Niti tubing can last through up to 10 million bends at levels found in the body. This is much better than stainless steel or cobalt-chromium alloys. The shape memory effect and superelasticity help the tubing handle stress without breaking. Devices like stents and catheters need this to last longer and not fail. You can count on niti for jobs that need strong fatigue resistance and long life.

Biocompatibility

Biocompatibility is very important for neurovascular uses. Nitinol tubing is very safe for the body and does not rust, so it lowers the chance of swelling or rejection. Surface treatments like electropolishing make the tubing smooth and safe. Studies show patients heal faster and have fewer problems with nitinol devices. Nitinol tubing is flexible and does not kink, so it protects soft tissues. You can use shape memory alloy tubing for blood vessels and soft tissue safely, knowing it meets tough medical rules for safety and how it works.

Shape Memory Alloy Tubing Applications

Nitinol Tubing for Neurovascular Stents

Doctors use shape memory alloy tubing to make safe stents. Nitinol tubing helps stents stretch and fit inside tricky blood vessels. This lets blood flow well and keeps the vessel safe from harm. These stents work well, with success rates up to 97%. They can change shape to fit each patient’s blood vessels. This helps blood move better and lowers the chance of the vessel getting blocked again.

Nitinol tubing is strong and does not break after many heartbeats. This means the stent lasts a long time and works well. The tubing does not rust, so it stays safe in the body. Patients heal faster and feel less pain because the stent fits the vessel’s shape. Studies show people have fewer problems and leave the hospital sooner. When picking a stent, you must match the tubing size to the blood vessel. Stents need to be flexible, strong, and safe for the body. These things make nitinol tubing the best pick for important medical jobs.

Other Medical Uses

Shape memory alloy tubing is used in many medical tools. You find it in heart implants, guidewires, catheters, and surgery tools. Making a device with nitinol lets you build strong and steady implants. Nitinol in guidewires and catheters makes them bendy and tough. This helps doctors move through the body’s twists and turns.

Here is a table showing new uses:

Emerging Medical Use | Description and Benefits |

|---|---|

Orthopedic Implants | Moves with the body, lowers rejection, and lasts longer. |

Catheters & Surgical Tools | Bends easily, causes less harm, and goes back to shape. |

Personalized Medicine | Grows at body heat for a good fit and fast healing. |

Emerging Innovations | Helps deliver cells and tiny parts for new treatments. |

More doctors want shape memory alloy tubing for new medical ideas. You see nitinol in many new tools, and more people want these materials every year.

Buy Nitinol Tubing

Size & Tolerances

When you buy nitinol tubing, you must pick the right size. The inner diameter, outer diameter, and length must fit your device. Medical-grade nitinol tubing comes in many sizes. Outer diameters are often between 0.2 mm and 2 mm. For blood vessels, 1.61 mm is a common size. Wall thickness is usually from 0.1 mm to 0.3 mm. These small sizes help your device work well and fit in the body.

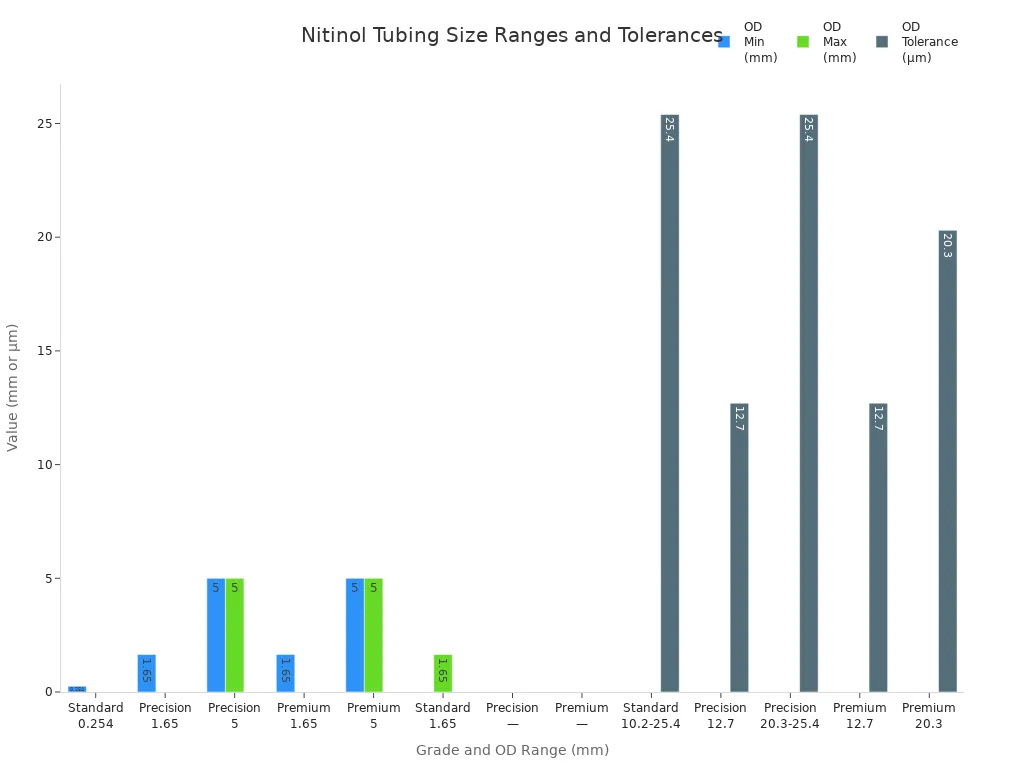

Manufacturers make different grades of nitinol tubing. Each grade has its own size range and tolerance. You can see the main choices in the table below:

Grade | Outer Diameter Range (inches/mm) | OD/ID Ratio | OD Tolerance (inches/µm) | Concentricity Tolerance | Typical Applications |

|---|---|---|---|---|---|

Standard | 0.010 - 0.065 (0.254 - 1.65) | 1.11 - 2.67 | +0.0003 to +0.001 (10.2 - 25.4) | N/A (Specified OD/ID) | Guidewires, catheters, needles, dental, disposables, sheaths |

Precision | 0.065 - 0.197 (1.65 - 5) | > 1.08 | ±0.0005 (12.7) | > 90% | Implants, delivery aides, stents, filters, orthopedic implants |

Premium | 0.065 - 0.197 (1.65 - 5) | > 1.08 | ±0.0005 (12.7) | > 95% | Critical implants, heart devices, neurovascular stents, carotid artery devices |

Premium | Various (thin wall) | < 1.08 | Dependent on OD & wall | > 95% | Thin-wall designs for advanced implantable devices |

You can also look at a chart that shows nitinol tubing grades by OD range and tolerance:

When you buy nitinol tubing, check that the tolerances meet ASTM F2633-07. Tight tolerances, like ±0.01 mm, help your device work safely. If you need special sizes, ask your supplier about custom options.

Tip: Always test samples before buying nitinol tubing. This helps you make sure the tubing fits your device and works for your needs.

Surface Finish

Surface finish is very important for how the device works and for safety. When you buy nitinol tubing, look for ones with good surface processing. Electropolishing takes away rough spots and nickel-rich layers. This makes a thin oxide layer that lowers nickel ion release and helps stop rust. Your device will last longer and stay safe in the body.

Other treatments like plasma and parylene coatings change the surface. These coatings help cells stick to the tubing and help healing. Smoother surfaces from processing lower protein build-up and reduce blood clots. They also help stop allergic reactions.

A good surface finish helps stop rust. This keeps ions from leaking out and stops the tubing from breaking down in the body. Surface processing also lowers friction and wear when using the device. This makes the device easier to use and more comfortable for patients.

Studies show electropolishing can make the surface up to 75% smoother. It can also make the tubing last about 20% longer. Coatings like parylene lower friction in blood vessels and help stop tissue irritation. Plasma and laser processing make the surface better for healing and lower the chance of breaking in implants.

Note: When you buy nitinol tubing, always ask about the surface processing. The right finish keeps your device strong, safe, and reliable.

Customization Options

Customization is very important when you buy nitinol tubing for new medical devices. Modern methods let you make special shapes and patterns without losing superelasticity or shape memory. Laser cutting is a top way to customize tubing. You can add small holes, slots, or special patterns to help the device work better.

Femtosecond and fiber lasers help with careful cutting. Femtosecond lasers use very fast pulses to cut with almost no heat. This keeps the tubing’s properties safe and makes smooth edges. Fiber lasers make some heat, but using gas like argon stops oxidation and keeps the tubing strong.

After laser cutting, electropolishing removes sharp bits and makes a smooth oxide layer. This step helps the tubing be safe for the body and stops rust. Premium tubing can be cut to within ±12.7 micrometers, which is important for stents, catheters, and implants.

You can pick from different laser cut patterns:

Interrupted Spiral Cut: Has flexible and solid parts for bending and strong turning, good for catheter shafts.

Spiral Cut: Gives steady flexibility, great for moving through tight blood vessels.

Puzzle Cut: Uses locking shapes to join materials and keep a clear opening.

Other options include coatings like titanium nitride and hydroxyapatite. These coatings help stop wear and help the device stick to bone or tissue. Customization is used in heart care, bone care, and many other areas.

When you buy nitinol tubing, talk to your supplier about your needs. The right choices will help your device work better and help patients feel better.

Supplier Selection

Certifications & Quality

When picking a supplier for medical grade tubing, check their certifications first. ISO 13485 is the main certification in the United States and Europe. This means the supplier follows strict rules for quality and safety. It also shows the tubing meets FDA and EU Medical Device Regulation rules. Good suppliers also meet ASTM F2063 and ISO 10993-1 for biocompatibility and material standards.

Quality is more than just having certificates. The best suppliers keep careful records for every batch they make. They track tubing from raw materials to delivery. They use digital systems and AI tools to find defects and track each tube. This helps you fix problems fast if something goes wrong. Companies like HaoLu Tech use machines to check every tube for safety and quality.

Tip: Always ask for papers that prove the tubing meets ISO 13485 and other important standards.

Technical Support

Good technical support helps you turn ideas into real products. Top suppliers help you from design to making the final product. They give advice on tubing size, wall thickness, and shape memory features. You can get help with custom work like laser cutting and surface treatments.

Some suppliers, like Viant Medical and Nordson MEDICAL, have made tubes for many years. They help with making samples, small or big orders, and extra services like heat treating and coating. Their teams help you solve problems and make your device better. Custom options let you match tubing to your device, making it safer and work better.

Prototyping and making lots of tubes

Custom work and special surface finishes

Engineering help for design and testing

Supply Chain Reliability

A strong supply chain keeps your project moving. Nitinol is special, and only a few companies make good tubing. Make sure your supplier can fill your order and deliver on time. If there are delays or shortages, your device launch could be late.

The best suppliers use smart ways to avoid problems. They keep extra tubing in stock and work with many shipping partners. They control every step of making the tubing. This helps them handle changes in demand and avoid long waits. Suppliers also give you clear records, like Device Master Records and batch tracking, so you can follow each tube from start to finish.

Supply Chain Best Practices | Benefits for You |

|---|---|

Inventory buffers | Fewer delays |

Multiple logistics partners | Reliable delivery |

Vertical integration | Consistent quality and supply |

Full documentation | Easier audits and compliance |

Note: Test sample tubing before making big orders to check quality and performance.

Picking nitinol tubing for your medical device means you must look at Af temperature, fatigue resistance, and how good the supplier is. You need to check tubing choices in a careful way:

Evaluation Aspect | Description and Importance |

|---|---|

Certifications | Make sure it meets ISO, FDA, and CE rules for safety. |

Size & Tolerances | Pick tubing that fits your project’s size needs. |

Fatigue Resistance | Look at supplier info to see if it lasts a long time. |

Surface Condition | Check that the finish helps stop rust. |

Quality Documentation | Ask for records and test results you can track. |

A checklist helps you remember all the important things, like how strong the tubing is and how smooth it feels. Talk with suppliers and experts to make the tubing right for your project and to not make mistakes. This way, your device will work better and it will be easier to get approval from the rules.

FAQ

What is the most important factor when choosing nitinol tubing?

You need to pick an Af temperature close to body temperature. This helps your device work right inside the body. The right Af temperature keeps superelasticity and shape memory working.

How do you verify the quality of nitinol tubing?

You can look for these things:

ISO 13485 certification

ASTM F2063 compliance

Batch traceability

Always ask your supplier for papers and test results.

Can you customize nitinol tubing for unique device designs?

Yes, you can ask for:

Custom diameters and wall thickness

Special laser-cut patterns

Surface coatings

Talk to your supplier about what your device needs before you buy.

Why does surface finish matter for medical nitinol tubing?

A smooth surface finish helps stop rust and nickel from coming out. It also makes your device last longer and keeps patients safer. Electropolishing and coatings make the tubing better for use in the body.

See Also

The Role Of Nitinol Tubes In Future Medical Devices

The Manufacturing Process Behind Nitinol Tubing For Medicine

Nitinol Tubing Transforming The Medical Device Industry Today