Get the Best Bulk Nitinol Tubing Price for Medical Devices

Getting the best bulk nitinol tubing price per meter for medical devices takes planning.

Pick suppliers carefully to save money and maintain good quality.

Nitinol is special because it bends easily and is safe for the body.

It is very important in making medical tools.

Choose suppliers who have extensive knowledge about producing nitinol.

Check that the tubing meets strict medical regulations.

This way, you can secure good prices while ensuring compliance with the rules.

Key Takeaways

Pick suppliers wisely to get good quality and save money. Check if they have experience and positive reviews.

Make sure they have certifications like ISO 13485 and ASTM F2063. These prove the nitinol tubing is safe and high quality.

Ask for samples before ordering a lot. Testing samples shows if the tubing works well for medical needs.

Compare prices from different suppliers. This helps you find the best deal without losing quality.

Build strong connections with suppliers. Talking often can lead to better prices and useful market tips.

Finding Reliable Suppliers for Bulk Nitinol Tubing

Researching Supplier Reputation and Reviews

Choosing a supplier starts with checking their reputation. Look for companies with experience in making nitinol tubing. Search for certifications, customer reviews, and examples of their past work. A supplier with good feedback and successful projects shows they are trustworthy and care about quality.

Talk to the supplier's technical team about your needs. This helps you see if they understand medical-grade nitinol and follow rules. Ask for samples to test the tubing's quality and performance. Testing ensures the product meets your needs before ordering in bulk.

Working closely with the supplier is also important. A good partnership helps improve products and keeps your needs met. By doing this, you can find suppliers who focus on quality and reliability.

Verifying Certifications for Medical-Grade Nitinol

Certifications are key when picking a supplier for medical nitinol tubing. ISO 13485 certification proves the supplier follows strict safety and quality rules. This reduces risks like defects or recalls, which are critical in medical devices. Choosing ISO 13485-certified suppliers ensures better reliability and patient safety.

Suppliers should also meet ASTM standards, like ASTM F2063, which set safety rules for nitinol tubing. FDA approval is another must-have, as it involves strict testing to meet medical-grade standards. Reliable suppliers provide documents to confirm the tubing's quality and properties.

Evidence Type | Description |

|---|---|

ISO and ASTM Standards | Set safety and quality rules for nitinol tubing in medical devices. |

FDA Compliance | Requires strict testing to meet medical-grade certifications. |

Supplier Quality Assurance | Offers documents to confirm the tubing's material and properties. |

Checking these certifications ensures the tubing meets top standards for medical use.

Assessing Supplier Experience with Bulk Orders

A supplier’s ability to handle bulk orders is very important. Check if they can produce large amounts efficiently. Suppliers with advanced tools and high production capacity are better for big orders.

Customization is also key. See if the supplier can adjust the tubing to fit your project needs. This ensures the tubing matches your design and works as expected.

Look at factors like delivery times and reliability. Suppliers who stick to schedules help avoid delays. Regular checks of suppliers ensure they follow Good Manufacturing Practices (GMP) and other rules.

Metric | Description |

|---|---|

Confirms the nitinol meets strict standards for performance and safety. | |

Checks if the supplier can adjust tubing for specific needs. | |

Production Capabilities | Reviews if the supplier can handle large orders efficiently. |

Lead Times | Measures how quickly the supplier can produce and deliver. |

Delivery Reliability | Ensures the supplier delivers on time to avoid delays. |

By focusing on these points, you can pick a supplier who can handle your bulk nitinol tubing needs well.

Ensuring Quality Standards for Medical Applications

Understanding ASTM F2063 and Other Standards

Following rules makes sure nitinol tubing is safe for medical use. ASTM F2063 is a key rule. It tells how strong and flexible the nickel-titanium alloys should be. This rule makes sure the tubing works well in medical tools. Other important rules are ISO 13485 and FDA compliance. They check that the making process is safe and the tubing is good to use.

Important checks for nitinol tubing are:

Making sure sizes are correct.

Testing strength to handle pressure.

Checking if it's safe for the body.

These rules make sure the tubing is safe and works well in different uses.

Requesting Samples for Quality Verification

Asking for samples helps check nitinol quality before buying a lot. Samples let you test things like what it's made of and how strong it is. For example, special X-ray tests can check the tubing's makeup. Strength tests see how much it can bend and stretch.

Quality Check | How It's Tested |

|---|---|

Chemical Makeup | Special X-ray tests |

Shape and Size | Optical Keyence VHX-5000 |

Strength and Flexibility | Uniaxial tensile test INSTRON 5966 |

By checking these things, you make sure the tubing is good for medical use. Testing samples also finds problems like rust, which can affect how well the tubing works.

Evaluating Consistency in Tubing Dimensions and Properties

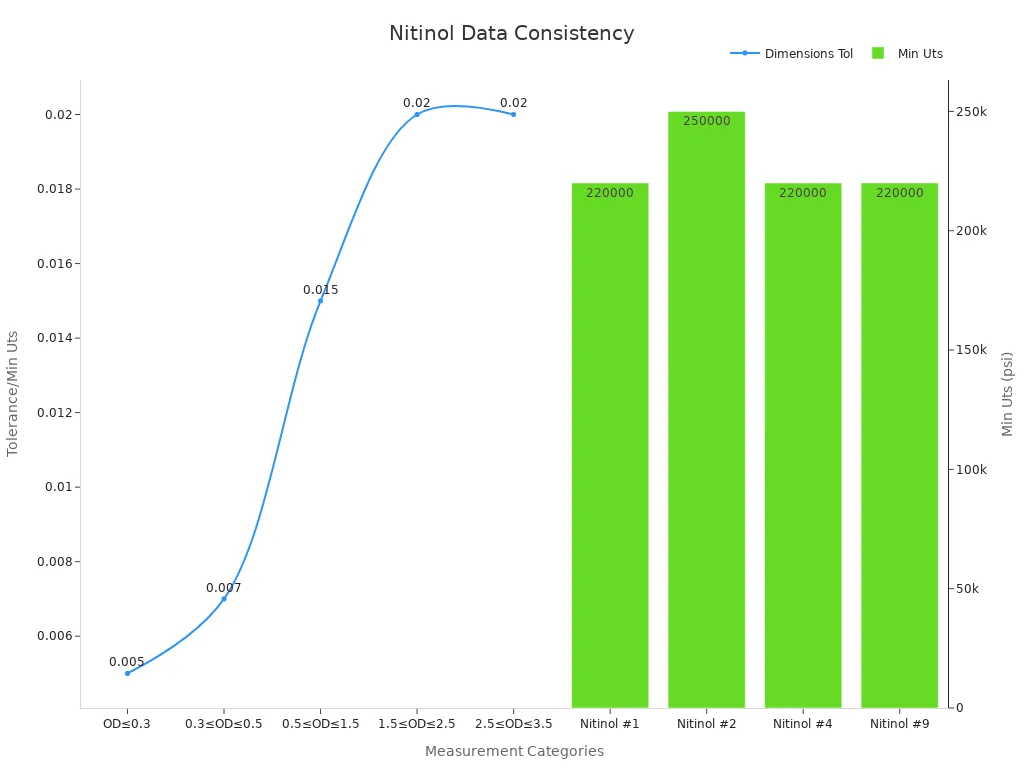

Being the same is important for nitinol used in medicine. Tubing must have exact sizes and materials to work right. For example, nitinol tubing has nickel (54.5-57.0%) and titanium, with few other things. Size rules change based on the tubing's outer size, making sure it's made right.

Property | Details |

|---|---|

Chemical Makeup (wt%) | Fe: ≤0.05, Ni: 54.5-57.0, Ti: Balanced, others ≤0.05 |

Size and Rules | OD≤0.3: ±0.005, 0.3≤OD≤0.5: ±0.007, 0.5≤OD≤1.5: ±0.015 |

Tests like Differential Scanning Calorimetry (DSC) and Bend Free Recovery (BFR) check the tubing's heat and bend properties. These tests make sure the tubing keeps its shape and bends back, which is important for medical tools.

Negotiating the Best Bulk Nitinol Tubing Price per Meter

Comparing Quotes Across Multiple Suppliers

To get the best price for nitinol tubing, compare quotes from different suppliers. Each supplier may have unique prices based on their production methods and costs. By checking multiple quotes, you can find good deals that meet your quality needs.

When asking for quotes, share clear details about the tubing. Include size, tolerances, and certifications needed. This helps suppliers give accurate prices and avoids surprises later. Use a table to compare suppliers by price, quality, delivery times, and extra services like customization.

Tip: Don’t pick the cheapest option without checking quality. Balancing cost and performance ensures the tubing works well for medical devices.

Using Bulk Orders and Long-Term Contracts

Buying in bulk is a smart way to lower costs for nitinol tubing. Suppliers often give discounts for large orders because it saves them money. Long-term contracts can also reduce costs by ensuring steady demand, helping suppliers plan better.

Ordering over 10,000 units yearly can cut costs by 18–22%.

Bulk buying and contracts can lock in prices, avoiding sudden increases.

Show suppliers you’ll buy regularly to get better deals. Reliable customers may get extra discounts or faster service. But always check that quality stays high for big orders. Regular inspections help ensure standards are met.

Timing Purchases for Better Prices

Market changes affect nitinol tubing prices. Costs for materials, demand shifts, and supply chain issues can raise or lower prices. Buying at the right time can save money.

Watch market trends to find times when material costs drop. For example, buying during low demand periods can lead to cheaper prices. Work with suppliers to learn their schedules and find cost-saving opportunities.

Note: Building strong supplier relationships can give you helpful market tips. This helps you plan purchases wisely.

By comparing quotes, using bulk orders, and timing purchases, you can save money while keeping quality high for nitinol tubing.

Managing Bulk Order Logistics

Knowing Minimum Order Quantities and Lead Times

Minimum order quantities (MOQs) are important for buying nitinol in bulk. Suppliers set MOQs to make production easier and more efficient. Ask about their MOQ rules before ordering. This helps you plan costs and avoid spending too much.

Lead times show how fast you’ll get your nitinol tubing. Shorter lead times help you meet tight schedules. Always check lead times early to prevent delays in your production.

Tip: Pick suppliers with fair MOQs and quick lead times. This way, you get good tubing on time.

Organizing Storage and Inventory

Storing nitinol tubing the right way keeps it in good shape. Use a clean, dry place to stop rust from forming. Keep the temperature steady, as extreme heat or cold can harm the tubing.

Tracking inventory helps you know how much tubing you have. Use software to check stock levels and plan when to reorder. This ensures you always have enough tubing for your projects.

Storage Checklist:

Clean, dry storage space

Temperature control tools

Regular checks for rust

Note: Good storage and tracking prevent waste and keep tubing high-quality.

Considering Shipping Costs and Customs Rules

Shipping costs can add a lot to your total price. Compare shipping fees from different companies to save money. Ask suppliers if they offer discounts for large shipments.

Customs rules differ by country. Make sure your nitinol tubing follows import and export laws. Work with suppliers who provide the right paperwork to avoid delays at customs.

Factor | Details |

|---|---|

Shipping Costs | Compare prices and ask for deals |

Customs Compliance | Check for proper documents |

Tip: Choose suppliers who know international shipping to make things easier.

Ensuring Compliance with Medical Manufacturing Standards

Following FDA and ISO Rules

Meeting FDA and ISO rules keeps nitinol safe for medical use. These rules require careful testing and records to prove the tubing meets strict standards. For example, FDA compliance includes inspections to check material makeup and size accuracy. Similarly, ISO 13485 ensures quality is maintained during production.

Following these rules helps in many ways. It lowers the chance of recalls or legal problems and makes products more reliable. For instance, meeting ASTM F2633-07 ensures nitinol tubing is fit for surgical implants and stents. By sticking to these rules, you can produce high-quality tubing and get better prices in the market.

Evidence Type | Description |

|---|---|

Certifies nitinol tubing for cardiovascular stents. | |

ISO and ASTM standards | Specify requirements for nickel-titanium alloys. |

FDA compliance | Ensures safety through testing and audits. |

Choosing Suppliers with Traceability

Picking suppliers who offer traceability improves quality checks. Traceability means you can track the tubing’s history, from raw materials to the final product. This helps confirm the tubing meets all rules and quality needs.

Suppliers with traceability provide certificates showing material details and consistency. They also use advanced tools like laser micrometry to check tolerances. This ensures the tubing is reliable. By working with such suppliers, you can deliver top-quality products to your customers.

Tip: Always ask for traceability papers to avoid problems and ensure quality in every batch.

Performing Regular Checks and Inspections

Regular checks are key to keeping nitinol tubing high-quality. These checks help find and fix any issues with meeting rules. For example, tests confirm the tubing meets ASTM and ISO standards for strength, flexibility, and size.

Skipping checks can cause big problems, like recalls or fines. Proper inspections, like ultrasonic tests and compliance certificates, reduce risks and confirm reliability. By doing regular checks, you ensure your tubing meets industry standards and stays high-quality.

Note: Skipping tests can lead to costly failures. Regular checks protect your products and reputation in the medical field.

Getting the best bulk nitinol tubing price needs careful planning. Look for trusted suppliers and check that quality stays the same. Work on good deals and manage storage and shipping well to save money.

Remember: Following FDA and ISO rules is a must. These rules keep products safe, reliable, and ready for medical use.

Use these tips to balance cost and quality. This way, you can buy nitinol tubing that fits your medical device needs without overspending.

FAQ

How long does it take to get bulk nitinol tubing?

The time depends on the supplier and order size. Most suppliers take 4–8 weeks to complete bulk orders. Always check delivery times before ordering to avoid delays.

How do you make sure the tubing is medical-grade?

Ask for certifications like ISO 13485 and ASTM F2063. Request traceability papers and test samples to check quality. These steps ensure the tubing is safe and works well for medical devices.

Do long-term contracts save money with suppliers?

Yes, they can help lower costs. Suppliers often give discounts for regular orders. Contracts also lock prices, protecting you from sudden price changes.

How should nitinol tubing be stored?

Keep it in a clean, dry place with steady temperatures. Avoid moisture and extreme heat. Check regularly for rust or damage to keep it in good condition.

Can nitinol tubing be customized for medical devices?

Yes, many suppliers offer customization. You can choose sizes, tolerances, and materials to fit your device. Talk to your supplier about your needs before ordering.

Tip: Clear communication helps ensure the tubing meets your exact needs.

See Also

Choosing the Right Nitinol Tubing Supplier for You

The Manufacturing Process of Nitinol Tubing for Medicine

Nitinol Tubing's Impact on the Future of Medical Devices