How to cut NiTi shape memory alloy tubes safely and efficiently

Cutting nitinol tubes needs special care. This material acts differently than normal metals. You will face many problems when you work with nitinol in factories.

Challenge | Description |

|---|---|

Thermal Sensitivity | Nitinol's crystal structures change with temperature, making cutting harder. |

Tool Wear | Nitinol's special features make tools wear out faster, so you must replace them often. |

Strain Hardening | Nitinol gets harder when bent or stretched, so it is tough to shape without mistakes. |

Precise Control of Parameters | You must control cutting settings well to stop mistakes when working with nitinol. |

Nitinol can change shape when it gets hot. This shape memory effect means you must watch the temperature. If not, the tube can bend or stop working right. The best way to cut niti shape memory alloy tube is to control heat and tool wear. This keeps the material working as it should. If you use the wrong way to cut, you can get tiny cracks or rough edges. These problems need more work to fix. Always try to cut nitinol tubes very carefully. This helps keep nitinol working as you want.

Key Takeaways

Pick laser or waterjet cutting for good results. These ways keep the nitinol tube cool. They help the tube keep its shape memory.

Always wear safety gear like goggles and gloves. This keeps you safe from sharp edges and flying bits.

Make sure your workspace is clean and neat. A tidy space stops accidents. It helps you pay better attention.

Use tools that are sharp and in good shape. Dull tools make too much heat. They can hurt the nitinol tube.

Watch the temperature closely when you cut. If the tube gets too hot, stop and let it cool. This keeps its special properties.

Best Way to Cut NiTi Shape Memory Alloy Tube

When you want the best way to cut niti shape memory alloy tube, you need to think about heat, precision, and how fast you can work. Nitinol is not like other metals. It reacts to heat and can lose its special shape memory if you use the wrong cutting method. You must choose a method that keeps the tube strong and keeps its shape memory.

Laser Cutting Methods

Laser cutting gives you high precision and clean edges. When you use a UV picosecond laser, you get even better results. This type of laser uses very short bursts of light. The heat does not spread far, so you get minimal thermal impact. This helps keep the nitinol tube’s shape memory and strength. Laser micromachining also makes less damage under the surface. You can cut very thin or complex shapes with this method. Many people use laser cutting for medical devices because you need high precision and smooth edges. If you want the best way to cut niti shape memory alloy tube, laser cutting is a top choice.

Tip: Always control the laser settings. Too much heat can change the nitinol’s properties.

Abrasive Waterjet Cutting

Abrasive waterjet cutting uses a stream of water mixed with tiny grains of sand. This method does not use heat, so the nitinol tube stays cool. You do not risk losing the shape memory effect. Waterjet cutting gives you smooth edges and keeps the tube strong. You can use this method for cutting nitinol sheets or tubes. It works well for both thick and thin materials. Waterjet cutting is fast and does not wear out tools quickly. Many factories use this method when they want the best way to cut niti shape memory alloy tube and keep the material safe.

Nonconventional machining like waterjet and laser cutting works better than old methods for nitinol.

Waterjet cutting reduces both mechanical and thermal damage.

You keep the shape memory and strength of the tube.

You get high precision and smooth cuts.

Manual Cutting Tools

Manual cutting tools, like saws or tube cutters, do not work well for nitinol. The metal is very tough and gets harder as you cut. You will see your tools wear out fast. The cut edges may look rough, and you might see burrs. Manual tools cannot give you high precision or smooth cuts. When you try cutting nitinol sheets or tubes by hand, you may damage the tube or lose its shape memory. Manual cutting is not the best way to cut niti shape memory alloy tube, especially if you need high precision or want to keep the tube’s special properties.

New technology helps you get better results. Factories now use 3D printing and new surface treatments to make nitinol tubes stronger and safer. Additive manufacturing lets you make complex shapes for medical and aerospace uses. These new ways of making and cutting nitinol tubes help you get the best way to cut niti shape memory alloy tube with less waste and better safety.

If you want to keep the tube’s shape memory and strength, choose laser or waterjet cutting. These methods give you high precision, smooth edges, and protect the special features of nitinol. Manual cutting tools do not give you the same results and can damage the tube.

Nitinol Cutting Process Steps

Preparation and Safety

Before you start cutting nitinol tubes, you need to prepare your workspace and tools. Always wear safety glasses and gloves. Make sure your area is clean and free from clutter. You should check that your cutting tools are sharp and in good condition. Sharp tools help reduce friction and heat, which is important for nitinol. If you use dull tools, you might create too much heat and damage the tube.

Tip: Use modern temperature monitors like pyrometers to keep an eye on heat during cutting. This helps you avoid activating the shape memory effect in nitinol.

Marking and Securing Tubes

You need to mark the nitinol tube where you want to make the cut. Use a fine marker or scribe for accuracy. Secure the tube in a clamp or fixture to keep it from moving. Make sure the clamp holds the tube firmly but does not crush it. If you use a rotary tool, create a glide path first. This step helps reduce the chance of the tube breaking during cutting. Always inspect your tools and clamps for wear before you start.

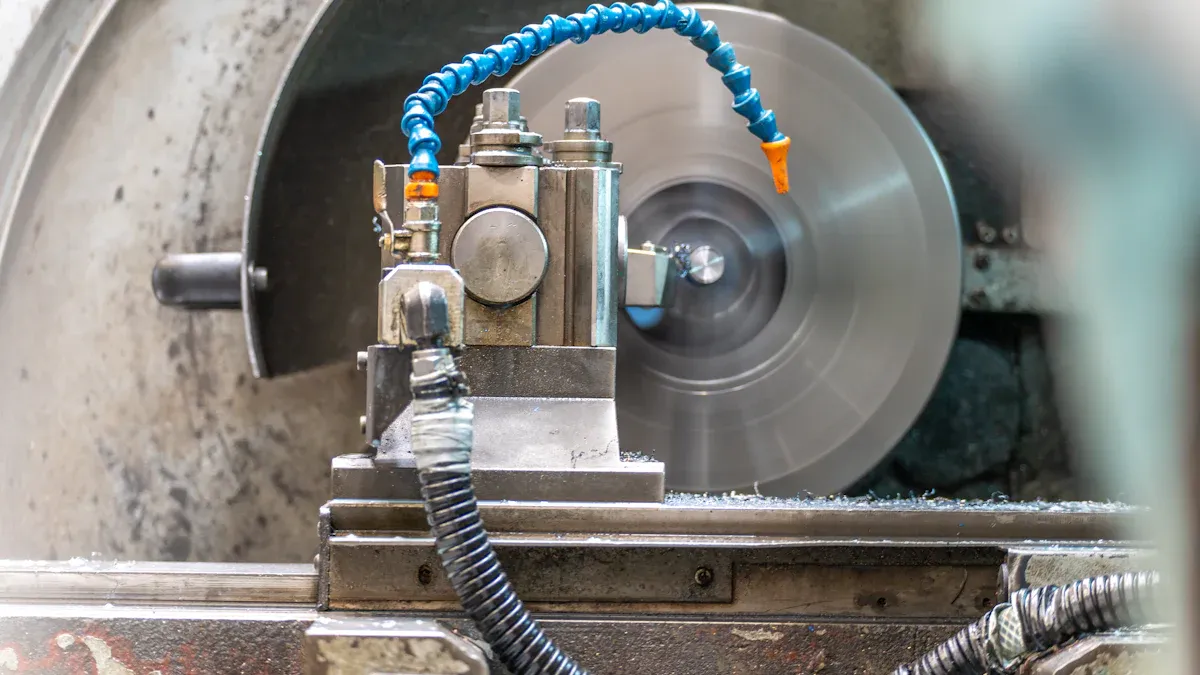

Cutting Execution

Follow these steps for safe and efficient cutting:

Set the cutting speed and feed rate to low values. This helps control heat and stress on the nitinol tube.

Start cutting gently. Do not force the tool through the tube.

Keep the tube cool by using water or air as needed.

Watch the temperature closely. If the tube gets too hot, stop and let it cool.

Move the tool smoothly and avoid bending or twisting the tube.

After cutting, check the edge for burrs or rough spots.

Note: If you need to restore the shape memory of nitinol after cutting, heat the tube above its transformation temperature and cool it quickly.

Troubleshooting Issues

Sometimes, you may see problems during cutting. Here are common issues and solutions:

Burrs or rough edges: Adjust your cutting tool settings or use assist gas.

Excessive dross: Lower the cutting power and improve airflow.

Tube slips in the clamp: Check and maintain your clamping system.

Inconsistent part sizes: Use cooling strategies and keep your equipment in good shape.

If you follow these steps, you can cut nitinol tubes safely and keep their special properties.

Post-Cutting Care for NiTi Tubes

Deburring and Cleaning

After you cut nitinol tubes, you must clean them. You need to get rid of sharp edges and leftover bits. This makes the cuts smooth and keeps your area safe. There are different ways to clean and deburr nitinol tubes:

Use a nylon brush and scrub the tube about 20 times. This helps remove loose pieces.

Put the tube in a 1% sodium hypochlorite solution for 10 minutes. This kills germs and does not hurt nitinol.

Place the tube in an ultrasonic bath for 5 minutes. The bath shakes off dirt from hard places.

Scrub with sponges and use special cleaning chemicals. This lowers the chance of germs.

Tip: Always rinse the tube with distilled water after using chemicals. This stops leftover stuff from staying on the tube.

Inspecting for Damage

You need to check nitinol tubes for damage after cutting. Careful checking helps you find cracks or rust early. Here are some ways to inspect tubes:

Method | Description |

|---|---|

Eddy Current Testing | Finds cracks and rust without touching the tube. |

Internal Rotary Inspection System (IRIS) | Uses sound waves to measure thickness and spot problems. |

Visual Inspection Using a Videoscope | Lets you see inside the tube with a tiny camera. |

Note: Checking tubes often helps you find problems before they get worse.

Preserving Material Properties

You want nitinol tubes to keep their special features after cutting. This means you must protect their shape memory and strength. You can use these ways:

Technique | Description |

|---|---|

Use of PCD dies | These diamond dies help keep tubes round and smooth. |

Interpass anneals | Heat the tube in a safe gas or vacuum to stop rust and keep its features. |

Clean the tube well at every step to keep it nice. | |

Laser cutting does not make hot spots, so the tube stays strong and keeps its memory. |

Use pure materials for laser work and clean the tube before cutting. Change laser power and speed to protect nitinol. Give the tube stress relief and polish it after cutting to make it last longer.

Tip: Careful steps after cutting help nitinol tubes stay strong and work well for their final job.

Safety Tips and Best Practices

Personal Protective Equipment

When you work with nitinol tubes, you must protect yourself. Cutting this material can send small pieces flying. You need to wear the right gear every time you start a cutting job. Here is what you should use:

Safety glasses or goggles keep your eyes safe from flying debris.

Gloves protect your hands from sharp edges on the tube.

Good ventilation helps you avoid breathing in dust or small particles.

Choose tools made for hard materials like nitinol to make cutting safer.

Keep heat low to protect both you and the tube’s special properties.

Always keep your work area tidy to prevent accidents.

Make sure you know how to use each tool and understand nitinol’s unique features.

Tip: Training helps you use cutting tools the right way and keeps you safe.

Workspace Setup

A clean and organized workspace helps you cut nitinol tubes safely. Place all your tools within easy reach. Remove clutter from your table. Make sure your work area has enough light so you can see every detail during cutting. Use clamps or fixtures to hold the tube steady. This stops the tube from moving and keeps your hands safe. Always check that your ventilation system works well before you begin. Good airflow removes dust and keeps the air clean.

Tool Maintenance

Sharp and well-kept tools make cutting nitinol easier and safer. Check your tools before each use. Look for signs of wear or damage. Replace blades or bits that look dull. Clean your tools after every cutting job. Store them in a dry place to prevent rust. When you take care of your tools, you get smoother cuts and reduce the risk of accidents.

Note: Well-maintained tools last longer and help you keep the special properties of nitinol after cutting.

You can cut NiTi tubes well if you pick the right way and keep things cool. Laser and waterjet cutting help the tube keep its shape memory and strength. Always use sharp tools. Make sure your workspace is clean. Here are some important things to remember:

Cutting fast saves time and stops tools from breaking.

New designs, like PTN rotary files, help you get better cuts.

Leave at least 1 mm of the tube to keep it strong.

Use these tips to make sure your NiTi tubes stay safe and strong.

FAQ

What is the safest way to cut NiTi tubes?

You should use laser or waterjet cutting. These methods keep the tube cool and protect its special shape memory. Always wear safety gear and keep your workspace clean.

Can you cut NiTi tubes with regular tools?

You can try, but regular tools wear out fast and may damage the tube. You will get rough edges and might lose the tube’s shape memory. Use special cutting tools for the best results.

How do you stop NiTi tubes from overheating during cutting?

Keep the cutting speed low and use cooling methods like water or air. Watch the temperature closely. If the tube gets hot, stop and let it cool before you continue.

Why does NiTi lose its shape memory after cutting?

Too much heat during cutting can change the tube’s crystal structure. You must control the temperature to keep the shape memory. Use the right cutting method and check the tube after cutting.

See Also

A Comprehensive Approach to Selecting Nitinol Tubing Options

Understanding the Manufacturing Process of Nitinol Tubing for Medicine

Latest Innovations in Laser Cutting Technology for Nickel-Titanium Tubes

Detailed Instructions for Creating Nitinol Microtubing in Neurovascular Use

Finding the Most Cost-Effective Supplier for 2mm Nitinol Tubing