What Are the Benefits of Electropolished Nitinol Tubes for Endoscopic Devices

Electropolished nitinol tube for endoscopic devices offers numerous advantages. These tubes feature smoother surfaces and enhanced resistance to rust, making them cleaner and safer for use inside the body. The electropolished nitinol tube for endoscopic devices is also highly durable and resistant to breakage, contributing to safer and more reliable medical procedures. The table below highlights how these properties translate into clinical benefits:

Property/Aspect | Clinical Impact |

|---|---|

Corrosion Resistance | Reduced nickel release leads to fewer allergies and less irritation. |

Fatigue Resistance | Can withstand over 10 million bends, improving surgical safety. |

Biocompatibility | Minimizes adverse reactions, ensuring patient safety. |

Clinical Outcomes | 97% procedural success rate, with 96.7% aneurysm closure maintained after 12 months. |

Shape Memory & Flexibility | Navigates complex anatomy, allowing for greater precision by physicians. |

Regulatory Compliance | Manufactured in compliance with FDA and ISO standards, ensuring high quality. |

Key Takeaways

Electropolished nitinol tubes have very smooth surfaces. This helps lower friction and stops tissue damage. It makes surgeries safer and easier for doctors and patients.

These tubes do not rust easily. They also let out less nickel. This lowers the chance of allergies and infections in patients.

Nitinol tubing can bend without breaking. It goes back to its original shape every time. This helps doctors move through tricky body paths safely.

Electropolishing takes away tiny cracks and weak spots. This makes the tubes stronger and last longer for many uses.

Makers follow strict rules for quality and safety. This makes sure electropolished nitinol tubes are safe and work well in medical procedures.

Electropolishing for Medical Devices

What Is Electropolishing

Electropolishing is a process that helps make medical devices better. It uses electricity and chemicals to smooth out metal surfaces. This removes tiny bumps, dirt, and extra iron from nitinol tubing. The tubes become shiny, clean, and do not rust easily.

Electropolishing makes medical devices safer for people.

It gets rid of places where germs can hide, so cleaning is easier.

The process can take off a very thin layer, about 0.0001 inches, from each side of the tube for a smooth finish.

Smooth nitinol tubing helps doctors see better in surgery because there is less glare.

Electropolishing follows strict rules like ISO 13485:2016 and 9001:2015, so every tube is made well.

Nitinol tubing that is electropolished has no sharp edges and is easy to clean.

Electropolishing is important for endoscopic tubes. It makes them smooth, helps them last longer, and keeps patients safe.

Why Use Nitinol Tubing

Nitinol tubing is used in endoscopic devices because it has special features. Nitinol can bend and go back to its original shape. This helps doctors move the device in the body without it breaking or getting stuck.

Nitinol tubing is strong, bends easily, and is safe for people. It does not rust and can bend many times without breaking.

The table below shows why nitinol tubing is a good choice for endoscopic devices:

Property | Benefit for Endoscopic Devices |

|---|---|

Superelasticity | Moves through tricky paths without bending out of shape |

Shape memory and superelasticity | Goes back to its shape for better control |

High fatigue resistance | Can be used many times |

Less chance of causing problems in the body | |

Corrosion resistance | Stays strong inside the body |

Smooth surfaces | Makes infections less likely and cleaning simple |

Electropolishing makes these good things even better. Electropolished nitinol tubing is smooth, clean, and lasts a long time. These features help doctors do surgeries with smaller cuts and help patients heal faster. Nitinol tubing with electropolished surfaces lets doctors do safer and more dependable surgeries.

Benefits of Electropolished Nitinol Tube for Endoscopic Devices

Surface Smoothness

Electropolished nitinol tubing has very smooth surfaces. The electropolishing process takes away tiny bumps and rough spots. This makes the tube shiny, like a mirror. Water slides off more easily after electropolishing. The surface becomes smoother and attracts water better. Tubes with less than 0.2 μm roughness move easily in the body. This means less friction and less damage to tissue. Smoother tubes are less likely to crack or rust. This is important for medical devices that stay inside the body.

Surface Treatment | Sample Size (n) | Breakdown Potential < 800 mV (%) |

|---|---|---|

Mechanically Polished | 130 | 100% |

Electropolished | 290 | 13% |

This table shows electropolished nitinol tubes break down less often. This proves the finish is high quality. Smooth surfaces also stop bacteria from sticking. This makes cleaning easier and helps keep patients safe.

Corrosion Resistance

Electropolished nitinol tubing does not rust easily. The electropolishing process adds a thin titanium oxide layer. This layer stops nickel from coming out and keeps the tube from rusting. Electropolished tubes resist rust better than other types. They also release less nickel.

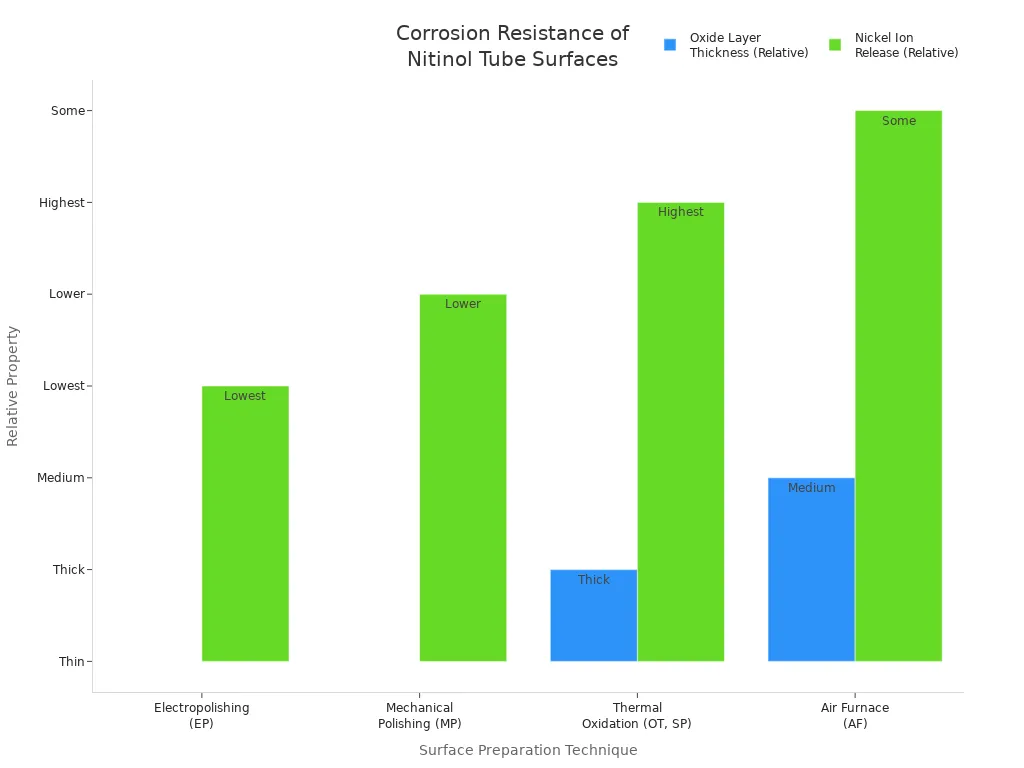

Surface Preparation Technique | Oxide Layer Thickness | Uniformity and Surface Characteristics | Correlation with Nickel Ion Release |

|---|---|---|---|

Electropolishing (EP) | Thin oxide layer | Smooth and even surface; removes nickel-rich spots | Strongly linked to less nickel release and better rust resistance |

Mechanical Polishing (MP) | Thin oxide layer | Even surface with chemical cleaning | Better than untreated but not as good as EP |

Thermal Oxidation (OT, SP) | Thick oxide layer (up to ~10 microns) | Not as even; can crack | More nickel comes out; rusts more easily |

Air Furnace (AF) | Medium oxide thickness | Not polished after heating | Some nickel comes out |

Electropolished nitinol tubes stay strong even after many uses. This helps them work well and stay safe inside the body.

Biocompatibility

Biocompatibility means the tube works well with the body. Electropolished nitinol tubing has a special oxide layer. This layer stops nickel from coming out and keeps the tube from rusting. Tests show electropolished tubes help over 95% of cells grow healthy. They also stop proteins from sticking. This lowers the chance of blood clots and swelling. Smooth tubes also cause less rubbing and wear. This makes the tube safer and helps it work better.

Electropolished nitinol tubing is safer for long-term use. It works well in devices like stents and catheters.

In blood tests, electropolished tubes cause less clotting and fewer platelets stick. These features lower the risk of allergies and skin problems during use.

Aspect | Effect of Electropolishing on Nitinol Tubes Used in Endoscopy |

|---|---|

Surface modification | Helps make a strong titanium oxide layer |

Corrosion resistance | Better, so tubes rust less |

Nickel ion release | Lower, so fewer allergies |

Biological reactions | Less chance of skin problems and allergies |

Surface smoothness | Smoother, so less irritation and tissue damage |

Regulatory relevance | Helps meet safety rules by controlling nickel release |

Overall biocompatibility | Better, so patients are safer during use |

Fatigue and Durability

Medical nitinol tubing needs to bend and stretch many times. Electropolished nitinol tubing is very strong and lasts longer. Electropolishing removes cracks and weak spots. This helps the tube bend more times before breaking.

Performance Aspect | Evidence of Improvement with Electropolishing (EP) | Supporting Details / Context |

|---|---|---|

Fatigue Resistance | Tube bends more times before breaking | Shown in BioRace endodontic tools |

Fatigue Failure Resistance | Electropolished tubes resist breaking from bending | Means tubes last longer under stress |

Surface Roughness | Surface is much smoother (Ra drops from ~0.85 to 0.08 μm) | Smoother tubes have fewer places for cracks to start |

Corrosion Resistance | Protective layer forms; less nickel comes out | Tubes rust less and stay strong |

Comparative Studies | Electropolishing works better than other methods | Tubes rust less and are smoother |

Medical Device Usage | Over 60% of heart stents use electropolished nitinol tubing | Shows doctors trust these tubes for better results |

Electropolished nitinol tubes keep their shape and work well after many bends. This makes them reliable for tough medical jobs.

Cleanliness and Safety

Cleanliness and safety are very important for medical tubes. Electropolished nitinol tubing has smooth surfaces that stop bacteria from sticking. Studies show smoother tubes have less bacteria like E. coli and Staphylococcus aureus. Electropolishing removes tiny flaws and dirt. This makes cleaning easier and lowers infection risk.

Electropolishing makes surfaces smooth so they do not snag tissue.

The finish is not porous and stays clean, stopping germs from growing.

These changes help keep patients safe by lowering infection risk and making devices work better.

Electropolished nitinol tubing also makes endoscopic tools stronger and more reliable.

Electropolished nitinol tubes are smoother, resist rust, work well with the body, last longer, and are cleaner. These features make them the best choice for safe and strong medical devices.

Device Performance and Clinical Impact

Flexibility and Kink Resistance

Nitinol tubing helps endoscopic devices bend and twist easily. These tubes move through the body’s tricky paths without breaking. They keep their shape even after bending. This is because nitinol has superelasticity. It lets the tube go back to its original shape.

Tests show medical nitinol wires and tubes are tough. They can bend many times and still work well. This is important for devices used in surgeries. These features help stop kinks and keep tubes flexible. Endoscopic devices work better when they move through the body.

Nitinol wire bends a lot without getting ruined.

This helps medical tools move through hard-to-reach places.

The strong material lowers the chance of kinks or breaks.

These features make devices safer and easier to use.

Patients are safer because the device works well.

Superelasticity and strong tubes help them last after many bends. This means surgeries are safer and patients do better.

Minimally Invasive Advantages

Electropolished nitinol tubes help make smaller, flexible devices. Their smooth surface stops stress spots and rust. This helps the tubes last longer inside the body.

Surface Finish | Breakdown Potential (mV) |

|---|---|

Oxidized Tubing | -117 |

Electropolished (EP) | Up to 1000 |

This table shows electropolished tubes resist rust much better. Nitinol’s superelasticity lets tubes bend sharply and have thin walls. The tube’s solid design means doctors use less force to move it. This makes surgery easier and safer for patients. These features help doctors do safer surgeries with fewer problems.

Reliability in Endoscopic Procedures

Electropolished nitinol tubes make endoscopic devices more reliable. Their smooth surface stops rust and breaking. Strong tubes can be used many times without snapping. Superelasticity and shape memory help the device keep its shape during surgery.

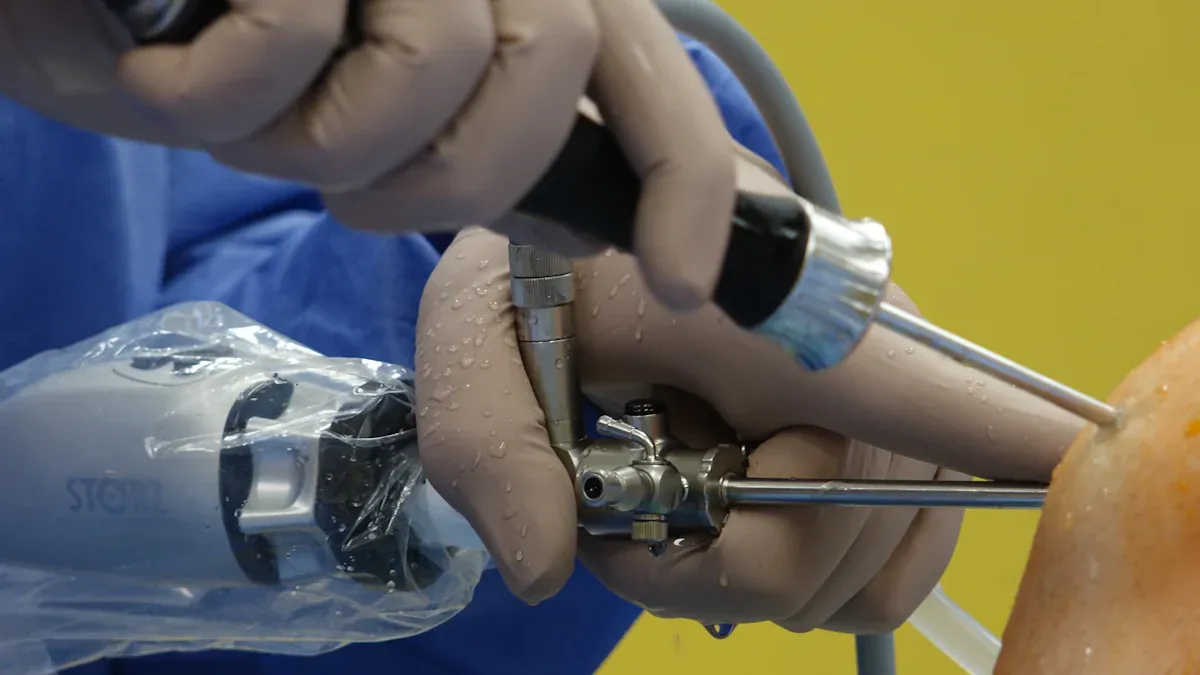

In robotic and endoscopic systems, nitinol tubes act like flexible arms. They move gently inside the body. For example, robotic bronchoscopes use curved nitinol tubes to reach deep into lungs. These tubes stay strong and flexible, so they hurt tissue less and keep patients safe. Electropolished nitinol tubes lower the chance of problems and help devices last longer. This means patients do better and devices work well every time.

Quality and Standards in Electropolishing Medical Devices

Certification and Compliance

Manufacturers must follow strict rules to keep people safe. They use high-quality nickel-titanium alloy for nitinol tubing. This gives the tubes superelasticity and shape memory. Certification and compliance are important for quality control. Companies must meet standards like ISO 13485, ASTM F2063, and ISO 10993. These rules help make sure the tubes are safe and strong for use in the body.

Regulatory agencies need full records for every batch of tubing. Manufacturers give certificates that show what the tubes are made of. They also show how strong the tubes are and their transformation temperatures. They keep records of biocompatibility tests and surface checks. These steps help doctors trust that electropolished medical devices are reliable.

Quality Parameter | Description / Value |

|---|---|

Shape Recovery Strain | About 4.16%, lets the tube return to its original shape |

Superelastic Strain | About 7%, allows bending without damage |

Chemical Composition | 55% nickel, 45% titanium, with strict impurity control |

Dimensional Tolerances | Precise outer and inner diameter measurements |

Biocompatibility Testing | Follows ISO 10993 for safety |

Meets ASTM F2063 and ISO 13485 standards |

Manufacturers also follow RoHS and REACH rules for the environment. These certifications show that electropolished medical devices meet world requirements.

Testing and Inspection

Testing and inspection help keep quality high for electropolished medical devices. Companies use special tools to check every tube. Laser micrometers measure the outside and inside of the tubes very closely. Ultrasonic and eddy current testing find hidden cracks or problems inside the tubes. Metallography and scanning electron microscopy check that heat-affected zones are gone, so the tubes stay strong.

100% dimensional inspection makes sure each tube matches the design.

Corrosion testing checks if the tube resists rust, which is important for implants.

Mechanical inspections test strength, elasticity, and fatigue resistance.

Biocompatibility tests follow ISO 10993 to make sure the tube is safe for patients.

Traceability systems track every step, from raw material to finished product.

A special method uses sodium hypochlorite soaking to find surface inclusions. Looking at the tube after soaking helps spot nickel reactions, but more checks are needed to avoid damage. All these steps help make sure electropolished medical devices are high quality and safe for doctors to use in surgery.

Quality Control Method | Description |

|---|---|

Ultrasonic Testing | Finds internal defects using sound waves |

Eddy Current Testing | Detects surface cracks with electromagnetic fields |

Dimensional Accuracy Inspections | Measures tube size with ±0.005 mm accuracy |

Corrosion Testing (ASTM F2129) | Checks resistance to rust for long-lasting implants |

Material Transformation Temperature Verification | Confirms phase changes for shape memory and superelasticity |

Manufacturers write down all test results and certifications. This makes sure medical nitinol tubing meets the highest standards for quality and safety.

Electropolished nitinol tubes have very smooth surfaces. They do not rust easily and work well with the body. Tests show they are as safe as other materials. Cell health is about the same for both groups:

Parameter | Nitinol Group | Control Group | P-value |

|---|---|---|---|

Endothelial Cell Count | 2290.5 ± 615.7 | 2326.7 ± 1005.1 | 0.8 |

Corneal Thickness (μm) | 656–682 | 645–684 | 0.5–0.9 |

Experts say nitinol’s superelasticity helps endoscopic tools bend and move.

Shape memory and fatigue resistance are also important features.

Electropolished nitinol tubing is a top choice for safe and strong medical devices.

FAQ

What makes electropolished nitinol tubes safer for patients?

Electropolished nitinol tubes have very smooth surfaces. They do not rust and let out less nickel. These things help lower allergies and infections. Doctors use these tubes because they are safer for patients.

How does electropolishing improve device performance?

Electropolishing takes away small bumps and cracks. It makes the surface shiny and even. Devices can move easily inside the body. This helps doctors do careful and steady surgeries.

Can electropolished nitinol tubes be used in long-term implants?

Yes, they can. Electropolished nitinol tubes work well with the body. They do not rust or wear out fast. These features make them good for stents and other implants that stay in the body for a long time.

Are electropolished nitinol tubes tested for quality?

Manufacturers check every tube for strength, size, and safety. They use special tools to look for cracks and rust. They follow strict rules like ISO 13485 and ASTM F2063.

See Also

The Importance Of Nitinol Tubing In Minimally Invasive Surgery

Nitinol Tubing Transforming The Future Of Medical Equipment

A Deep Dive Into Nitinol Tubing Uses In Healthcare Tools

The Process Behind Manufacturing Nitinol Tubing For Medicine