Advancements in Nitinol Tubing for Vascular Dilation Devices

Nitinol has revolutionized the field of vascular dilation devices. Its unique properties, such as shape memory and superelasticity, allow it to adapt to complex anatomical structures. These characteristics make it an ideal material for minimally invasive medical tools. Recent advancements in Nitinol Tubing for vascular dilation devices have further enhanced its performance. Improved manufacturing techniques and surface modifications ensure better biocompatibility and durability. These innovations contribute to safer procedures and faster recovery times, significantly improving patient outcomes. Nitinol continues to set new standards in medical device technology.

Key Takeaways

Nitinol tubing has special traits like shape memory and flexibility. These traits help it fit well in tricky body areas.

New ways to make Nitinol tubing improve its accuracy and use. This makes it work better in medical tools.

Special surface changes, like new coatings, make Nitinol safer. These changes lower the chance of bad reactions in patients.

3D printing helps create custom Nitinol devices for each person. This makes treatments work better and fit patients' needs.

Using AI and robots with Nitinol tools will change healthcare. It will make surgeries more exact and tools more flexible.

The Unique Properties of Nitinol Tubing

Nitinol tubing stands out due to its remarkable properties, which make it an essential material in vascular dilation devices. These unique characteristics include shape memory, superelastic properties, biocompatibility, and exceptional durability.

Shape Memory and Superelasticity

Nitinol exhibits shape memory, allowing it to return to its original form after deformation. This property is critical in vascular dilation devices, as it enables tools to adapt to the body's complex anatomy. Additionally, its superelastic properties allow it to withstand significant strain without permanent deformation.

Property | Nitinol | Other Materials |

|---|---|---|

Elasticity | Exceptional elasticity | Limited flexibility |

Superelasticity | Withstands significant strain | Limited strain capacity |

Flexibility | Highly flexible without kinking | Often rigid or less flexible |

These features ensure that Nitinol tubing performs reliably under challenging conditions, surpassing the capabilities of many traditional materials.

Biocompatibility and Corrosion Resistance

Biocompatibility is a crucial factor in medical devices, and Nitinol excels in this area. Its ability to integrate with human tissue minimizes the risk of adverse reactions. Furthermore, its corrosion resistance ensures long-term performance, even in the body's harsh internal environment.

Nitinol's biocompatibility and resistance to corrosion make it a safer choice compared to materials like stainless steel or titanium alloys. While stainless steel and titanium alloys have tensile strengths of approximately 550 MPa, Nitinol's tensile strength of 500 MPa is sufficient for most medical applications, with the added benefit of superior flexibility and adaptability.

Durability and Fatigue Resistance

Durability is another standout feature of Nitinol tubing. Its fatigue resistance ensures that it can endure repeated cycles of stress without failure. This property is particularly important in vascular dilation devices, which must perform reliably over extended periods.

Nitinol's ability to maintain its structural integrity under constant use sets it apart from other materials. Its combination of durability, shape memory, and biocompatibility ensures that it meets the rigorous demands of modern medical applications.

Latest Advancements in Nitinol Tubing for Vascular Dilation Devices

Innovations in Manufacturing Techniques

Recent advancements in material science have transformed the production of Nitinol tubing for vascular dilation devices. Enhanced processing methods now allow for greater precision and efficiency in manufacturing. Advanced machining techniques enable the creation of ultra-fine Nitinol wires and tubes. These innovations improve the superelasticity and thermal memory of the material, making it more versatile for medical applications.

Manufacturers have also adopted laser cutting and electrochemical machining to achieve intricate designs. These methods ensure that Nitinol tubing meets the stringent requirements of vascular dilation devices. By streamlining production, these techniques reduce waste and improve the overall quality of Nitinol medical devices.

Enhanced Surface Modification for Biocompatibility

Surface modification plays a critical role in improving the biocompatibility of Nitinol tubing. Advanced coating technologies, such as plasma electrolytic oxidation, create a protective layer on the material's surface. This layer enhances corrosion resistance and reduces the risk of adverse reactions when the tubing interacts with human tissue.

Polishing techniques, including electropolishing and mechanical polishing, further refine the surface of Nitinol tubing. These methods minimize imperfections, ensuring a smooth finish that promotes better integration with the body. Enhanced surface modification techniques contribute to the safety and reliability of Nitinol medical devices used in vascular dilation procedures.

Additive Manufacturing for Customization

Additive manufacturing, or 3D printing, has opened new possibilities for customizing Nitinol tubing for vascular dilation devices. This technology allows manufacturers to create patient-specific designs with unparalleled precision. By layering material incrementally, additive manufacturing produces complex geometries that traditional methods cannot achieve.

Customization through additive manufacturing improves the performance of Nitinol medical devices. Patient-specific designs ensure a better fit and functionality, leading to improved outcomes in vascular treatments. This approach also reduces production time, making it a cost-effective solution for healthcare providers.

Applications of Nitinol Tubing in Vascular Dilation Devices

Use in Stents and Guidewires

Nitinol tubing plays a critical role in the development of stents and guidewires. Its superelasticity allows stents to recover their original shape after deformation, making them ideal for navigating the complex anatomy of blood vessels. This property is especially beneficial in self-expanding stents, which automatically expand to fit the vessel's diameter. Nitinol's biocompatibility ensures that these stents integrate seamlessly with human tissue, reducing the risk of adverse reactions.

The flexibility of nitinol tubing enables guidewires to conform to the natural contours of blood vessels, minimizing the risk of vessel damage during procedures. Additionally, its fatigue resistance ensures that stents and guidewires maintain their structural integrity under repeated stress. Clinical studies have demonstrated improved success rates in cardiovascular treatments when nitinol stents are used.

Performance Metric | Benefit |

|---|---|

Superelasticity | Enhances performance in self-expanding stents. |

Biocompatibility | Improves patient safety and treatment reliability. |

Fatigue Resistance | Ensures durability under significant strain. |

Flexibility | Reduces the risk of vessel damage by conforming to natural contours. |

Clinical Outcomes | Higher procedural success rates in cardiovascular treatments. |

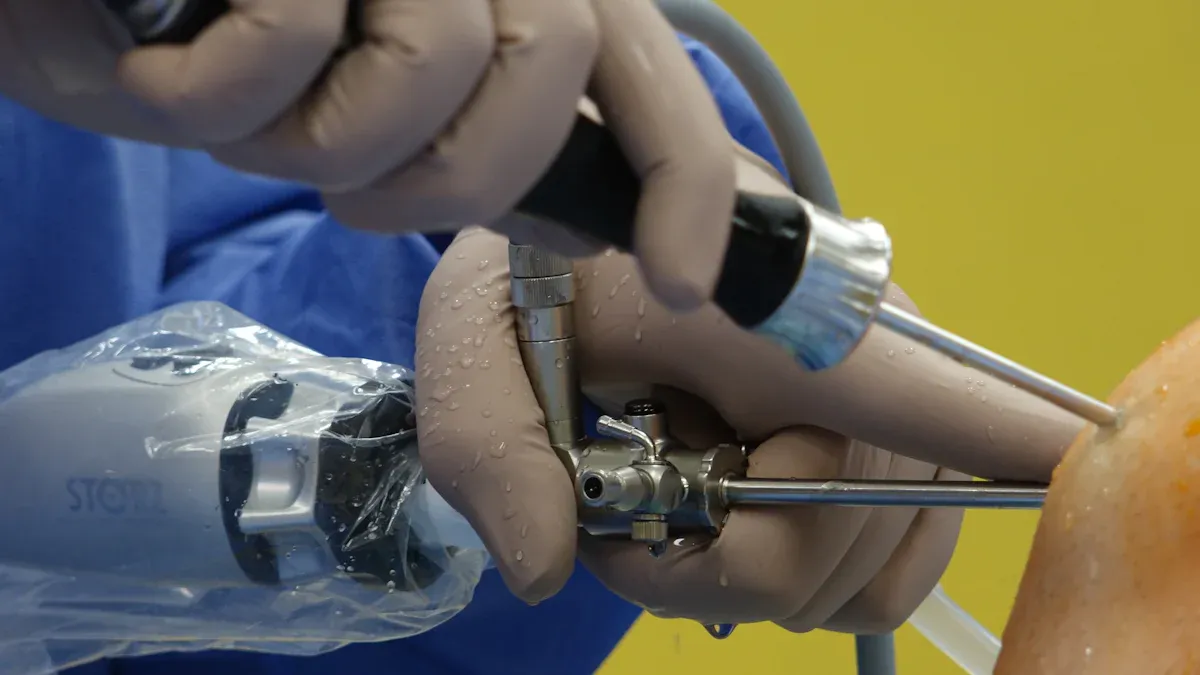

Role in Minimally Invasive Procedures

Minimally invasive procedures rely heavily on nitinol medical devices. The tubing's unique properties, such as shape memory and superelasticity, allow for precise navigation through narrow and tortuous pathways. Self-expanding stents made from nitinol tubing can be deployed with minimal trauma to surrounding tissues. This reduces recovery times and enhances procedural efficiency.

Catheters constructed with nitinol tubing also benefit from its flexibility and durability. These devices can navigate challenging vascular pathways without kinking or breaking. The use of nitinol in minimally invasive procedures has revolutionized cardiovascular treatments, offering safer and more effective options for patients.

Nitinol's adaptability and reliability make it indispensable in minimally invasive procedures, where precision and patient safety are paramount.

Improved Patient Outcomes in Vascular Treatments

The integration of nitinol tubing in vascular dilation devices has significantly improved patient outcomes. Self-expanding stents and drug-eluting stents made from nitinol provide long-term solutions for conditions like arterial blockages. These stents maintain vessel patency while delivering medication to prevent restenosis.

Nitinol medical devices used in catheters and guidewires enhance procedural success rates by reducing complications. Their biocompatibility minimizes the risk of inflammation or rejection, ensuring better healing. Patients undergoing minimally invasive procedures with nitinol-based devices experience shorter hospital stays and faster recoveries.

The advancements in nitinol applications continue to set new benchmarks in cardiovascular treatments. By improving the safety and effectiveness of vascular dilation devices, nitinol tubing has transformed patient care and outcomes.

Future Trends in Nitinol Medical Devices

Integration with AI and Robotics

The integration of AI and robotics with nitinol medical devices is transforming healthcare. AI-driven models analyze data to predict the stress-strain response and fatigue resistance of nitinol components. These insights enhance the performance and reliability of medical devices. Robotics, combined with nitinol's flexibility, enables the creation of highly precise surgical tools. For example, robotic-assisted systems use nitinol-based instruments to navigate complex anatomical pathways with minimal trauma.

Tier | Description |

|---|---|

Information Tier | Methods for acquiring data on implant deformation and quantifying uncertainty to ensure credibility in data-driven methods. |

Knowledge Tier | Fusion of data from various sources to create descriptive and predictive models for phenomena like fatigue. |

Prediction Tier | Development of data-driven models for stress-strain response or fatigue resistance using machine learning techniques. |

These advancements improve the adaptability and precision of nitinol medical devices, making them indispensable in modern healthcare.

Advancements in Material Science and Design

Material science innovations are driving the evolution of nitinol medical devices. Improved processing methods enhance production efficiency and allow for the creation of nitinol tubes with superior superelasticity and thermal memory. Advanced machining techniques enable the development of devices that withstand extreme stress and temperature variations.

Nitinol's unique properties allow for the customization of medical devices to match individual patient needs.

Shape memory and biocompatibility enable tailored designs that conform to specific anatomical structures.

The global nitinol implants market is projected to reach $1.6 billion by 2027, reflecting the growing demand for these advanced medical devices.

These advancements ensure enhanced flexibility and durability, making nitinol tubing a cornerstone of modern medical applications.

Potential New Applications in Healthcare

Nitinol's versatility opens doors to new medical applications. Its shape memory and superelastic properties, combined with drug-eluting technologies, have shown promise in reducing restenosis in cardiovascular treatments. Emerging studies highlight its potential in neurosurgery, gastroenterology, and urology. Personalized medicine also benefits from nitinol's adaptability, enabling the development of devices tailored to individual patient needs.

Significant potential exists for nitinol in neurosurgery, gastroenterology, and urology.

Drug-eluting nitinol stents reduce restenosis in cardiovascular applications.

The rise of personalized medicine offers opportunities for tailored nitinol medical devices.

These innovations position nitinol tubing as a key material for future healthcare advancements, addressing diverse medical challenges with precision and reliability.

Nitinol tubing has redefined the standards for vascular dilation devices through its exceptional properties and continuous advancements. Its biocompatibility, elasticity, and fatigue resistance make it indispensable in modern medical applications. These characteristics ensure safer procedures and improved patient outcomes.

Recent innovations, such as additive manufacturing and enhanced surface modifications, have further expanded its capabilities. Medical devices now represent the largest segment of the nitinol shape memory alloy market, with the global nitinol implants market projected to reach $1.6 billion by 2027, growing at a CAGR of 8.7%.

Characteristic | Description |

|---|---|

Biocompatibility | Nitinol's compatibility with tissue reduces adverse reactions. |

Elasticity | Its elasticity enhances the performance of medical devices. |

Fatigue Resistance | Nitinol can endure repeated deformation cycles, ensuring durability. |

The future of nitinol tubing holds immense promise. Its integration with AI, robotics, and personalized medicine will likely unlock new possibilities in healthcare. As advancements continue, nitinol will remain at the forefront of medical innovation, transforming patient care and outcomes.

FAQ

What makes Nitinol tubing ideal for vascular dilation devices?

Nitinol tubing offers shape memory, superelasticity, and biocompatibility. These properties allow it to adapt to complex anatomical structures while maintaining durability. Its corrosion resistance ensures long-term performance, making it a reliable choice in healthcare applications.

How does Nitinol improve minimally invasive procedures?

Nitinol's flexibility and fatigue resistance enable precise navigation through narrow pathways. Devices made from Nitinol tubing reduce trauma to surrounding tissues, enhancing procedural efficiency. This innovation has transformed healthcare by offering safer, less invasive treatment options.

Can Nitinol tubing be customized for individual patients?

Yes, additive manufacturing allows for patient-specific designs. This technology creates complex geometries tailored to individual needs, improving device performance. Customization enhances healthcare outcomes by ensuring a better fit and functionality for each patient.

What role does surface modification play in Nitinol tubing?

Surface modification enhances biocompatibility and corrosion resistance. Techniques like plasma electrolytic oxidation and electropolishing create smooth, protective layers. These advancements improve the safety and reliability of Nitinol devices in healthcare.

What are the future trends for Nitinol in healthcare?

Future trends include integrating Nitinol with AI and robotics for precision tools. Advancements in material science will further enhance its properties. Emerging applications in neurosurgery, gastroenterology, and urology highlight its growing importance in healthcare innovation.

See Also

Nitinol Tubing's Impact on Modern Medical Innovations

Transforming Medical Devices Through Nitinol Tubing Technology

Investigating Nitinol Tubing Uses in Healthcare Equipment