Why FEP Dielectric Tubing is Superior to Other Insulation Materials

FEP dielectric tubing, particularly the 600V/mil FEP Dielectric Tubing, stands out as a premier choice for insulation due to its exceptional properties. Industries such as aerospace, automotive, and medical devices increasingly rely on its reliability for demanding applications. The material's ability to resist harsh chemicals and tolerate extreme temperatures ensures consistent performance in challenging environments. For example, aerospace applications benefit from its use in aircraft wiring systems, where it withstands both high heat and chemical exposure. Similarly, the electronics sector values its role in protecting sensitive components, especially as miniaturization trends demand robust wire insulation. With advancements in manufacturing, the 600V/mil FEP Dielectric Tubing continues to meet the growing need for high-performance solutions.

Key Takeaways

FEP tubing resists chemicals well, working in tough environments others can't.

It handles very hot and cold temperatures, from -200°C to 200°C.

This makes it dependable for use in cars and airplanes.

FEP is great at insulating electricity, protecting wires in high-voltage systems.

It bends easily, fitting into small spaces for medical and tech uses.

Though it costs more, its strength and lasting quality make it worth it.

Key Properties of FEP Dielectric Tubing

Chemical Resistance

Resistance to harsh chemicals and solvents

FEP exhibits unparalleled chemical resistance due to its unique molecular structure. Its backbone, composed of carbon atoms bonded to fluorine atoms, forms one of the strongest bonds in organic chemistry. This structure ensures that FEP resists breaking down when exposed to oils, solvents, and corrosive chemicals. Industries rely on FEP for applications involving strong acids like sulfuric acid and bases such as sodium hydroxide. Its ability to withstand a wide range of chemicals makes it indispensable in environments where other materials fail.

FEP resists exposure to strong acids and bases.

It remains unaffected by organic solvents, ensuring long-term durability.

Non-reactive nature in extreme environments

The high electronegativity of fluorine creates a non-polar, non-reactive surface on FEP. This property prevents interactions with hydrocarbons and oils, making it ideal for use in chemically aggressive environments. Whether in industrial chemical processing or medical applications, FEP maintains its integrity, ensuring reliable performance even under extreme conditions.

Thermal Stability

High-temperature tolerance from -200°C to 200°C

FEP heat shrink tubing demonstrates exceptional temperature resistance, operating effectively across a wide range from -200°C to 200°C. This high-temperature performance ensures that FEP retains its structural integrity in demanding applications. For instance, aerospace fuel lines utilize FEP tubing to handle aviation fuels and hydraulic fluids during extreme temperature variations.

Insulation Materials | Heat Contributed (MJ/kg) | Heat Contributed (BTU/lb) |

|---|---|---|

Polyethylene | 46.5 | 20,000 |

PVC | 20.9-30.2 | 9,000-13,000 |

Rubber | 23.3-32.6 | 10,000-14,000 |

FEP | 5.1 | 2,200 |

FEP's low heat contribution highlights its superior thermal stability compared to other materials, making it a preferred choice for high-performance applications.

Performance in both hot and cold conditions

FEP heat shrink tubing excels in environments with extreme temperature fluctuations. In aerospace and automotive industries, it insulates wiring and protects components from thermal stress. Its ability to perform in high-temperature environments ensures reliability in critical systems, such as aircraft wiring and industrial machinery.

Electrical Insulation

600v/mil fep dielectric tubing for high dielectric strength

FEP offers excellent dielectric properties, with a dielectric strength ranging from 20 to 30 kV/mm. This makes it suitable for high-voltage applications, where it prevents electrical breakdown and interference. The 600v/mil FEP dielectric tubing is particularly valued for its ability to safeguard sensitive wiring in high-voltage systems.

Consistent performance in high-frequency applications

FEP's low dielectric constant minimizes signal loss, making it ideal for high-frequency applications. Its low dissipation factor enhances its effectiveness as an insulator, ensuring consistent performance in precision electronics. Industries such as telecommunications and aerospace benefit from FEP's ability to maintain electrical insulation under demanding conditions.

Mechanical Properties

Flexibility for Tight Spaces and Ease of Installation

FEP dielectric tubing offers exceptional flexibility, making it an ideal choice for applications requiring precise installations in confined spaces. Its optimal flex-life ensures that the tubing can bend and twist repeatedly without cracking or losing its structural integrity. This property is particularly valuable in industries like aerospace and automotive engineering, where wiring systems often need to navigate through tight and complex pathways.

The tubing's stress-cracking resistance further enhances its reliability, allowing it to maintain performance even under mechanical stress. For example, in laboratory equipment, FEP tubing is used in chromatography systems, where its flexibility ensures smooth fluid transfer without compromising accuracy. Additionally, its lightweight nature simplifies installation, reducing labor time and effort.

Property | Description |

|---|---|

Excellent resistance to wear | FEP is known for its durability against wear and abrasion. |

Optimal flex-life | It has a long flex-life, contributing to its flexibility. |

Stress-cracking resistance | FEP resists stress-cracking, enhancing its longevity and reliability. |

Resistance to Wear and Abrasion

FEP tubing demonstrates outstanding durability, resisting wear and abrasion even in harsh environments. This makes it a preferred material for applications involving repeated mechanical contact or exposure to abrasive substances. For instance, in the chemical processing industry, FEP tubing safely transfers corrosive chemicals without degrading over time. Its wear resistance ensures long-term reliability, reducing the need for frequent replacements.

Industries that benefit from FEP's mechanical properties include:

Chemical Processing: Transfers corrosive chemicals safely due to exceptional durability.

Pharmaceutical Industry: Ensures sterile fluid transfer in bioprocessing systems.

Food and Beverage Sector: Handles food items hygienically while resisting abrasion.

Aerospace Engineering: Protects fuel lines from wear caused by aviation fuels.

Laboratory Equipment: Maintains performance in analytical instruments requiring chemical compatibility.

FEP's combination of flexibility and wear resistance makes it a versatile solution for demanding applications across various industries. Its ability to withstand mechanical stress while maintaining performance ensures that it remains a top choice for high-performance insulation needs.

Comparison with Other Insulation Materials

FEP vs. PTFE

Similarities in chemical resistance and thermal stability

FEP and polytetrafluoroethylene (PTFE) share remarkable chemical resistance and thermal stability. Both materials withstand exposure to aggressive chemicals and solvents, making them ideal for harsh environments. Their non-reactive nature ensures durability in industrial and high-voltage systems. Additionally, both materials perform well under extreme temperatures, maintaining their structural integrity in demanding applications.

Differences in flexibility, optical clarity, and cost

Despite their similarities, FEP and PTFE differ in several key areas:

Temperature Resistance: PTFE tolerates higher temperatures, up to 260°C, compared to FEP's maximum of 200°C.

Flexibility: FEP offers greater flexibility, making it suitable for thin-walled tubing and applications requiring precision.

Optical Clarity: FEP is transparent, while PTFE is opaque, giving FEP an advantage in applications requiring visibility.

Cost: PTFE is generally more expensive due to its superior dielectric strength and higher temperature tolerance.

FEP's melt processability makes it a preferred choice for insulating cables in high-voltage systems, where precision and thinness are critical.

FEP vs. UPE

Superior chemical and thermal resistance of FEP

FEP surpasses ultra-high molecular weight polyethylene (UPE) in chemical resistance and thermal stability. It endures prolonged exposure to corrosive substances without cracking or becoming brittle. FEP also performs better in high-temperature environments, making it ideal for high-voltage systems requiring reliable electrical insulation.

Applications where UPE may be preferred

While FEP excels in chemical resistance and thermal stability, UPE offers advantages in specific applications:

Application Type | Reason for UPE Preference |

|---|---|

Hoses for abrasive materials | High abrasion resistance required |

Hoses for corrosive chemicals | Excellent chemical resistance needed |

UPE's abrasion resistance makes it suitable for handling abrasive materials, while its chemical resistance supports its use in less demanding environments.

FEP vs. EPDM

Electrical insulation and temperature performance comparison

FEP outperforms ethylene propylene diene monomer (EPDM) in electrical insulation and temperature tolerance. Its high dielectric strength ensures reliable performance in high-voltage systems, while EPDM's lower dielectric properties limit its use in such applications. FEP also withstands a broader temperature range, making it suitable for extreme environments.

Situations where EPDM may be more cost-effective

EPDM offers a cost-effective solution for applications where high-performance insulation is unnecessary. It provides adequate resistance to weathering and ozone, making it a practical choice for outdoor applications. However, industries requiring superior chemical resistance and high-voltage electrical insulation often favor FEP despite its higher cost.

FEP vs. Other Materials (e.g., PVC, Silicone)

Advantages of FEP in High-Performance Applications

FEP offers several advantages over materials like PVC and silicone, particularly in demanding environments. Its corrosion resistance ensures durability when exposed to harsh substances, making it ideal for chemical processing and industrial applications. Unlike PVC, which can degrade under prolonged UV exposure, FEP resists UV radiation, maintaining its structural integrity in outdoor settings. Additionally, its excellent barrier properties against gases and water vapor enhance its reliability in sensitive applications such as medical devices and electronics.

FEP's high purity grade makes it suitable for environments requiring minimal contamination, such as pharmaceutical and food industries. It can also be welded and re-molded effectively, allowing for customization in complex systems. Its stability in harsh environments, combined with resistance to chemicals and solvents, ensures consistent performance over time. Furthermore, FEP demonstrates superior dielectric strength and a low dielectric constant, making it a preferred choice for high-frequency electrical insulation. Minimal moisture absorption further enhances its suitability for precision applications.

Trade-Offs in Cost and Specific Use Cases

While FEP excels in high-performance applications, its higher cost compared to PVC and silicone can be a limiting factor. PVC, for instance, offers a more economical solution for general-purpose insulation, particularly in low-stress environments. Silicone, known for its flexibility and thermal stability, may be preferred in applications requiring extreme temperature tolerance without the need for high chemical resistance.

FEP's advantages often justify its cost in industries where performance and reliability are critical. However, for less demanding applications, the cost-effectiveness of PVC or silicone may outweigh the benefits of FEP. Each material serves specific use cases, and the choice depends on the application's requirements for durability, chemical resistance, and electrical insulation.

Applications of FEP Dielectric Tubing

Electronics and Electrical Industries

Use in high-frequency cables and wiring

FEP dielectric tubing plays a critical role in the electronics and electrical industries. Its exceptional dielectric strength ensures reliable insulation for high-frequency cables and wiring. This property minimizes signal loss and interference, making it indispensable in telecommunications and precision electronics. Additionally, FEP tubing's resistance to high temperatures and moisture enhances its durability and longevity in demanding environments.

Application | Description |

|---|---|

Electrical insulation | FEP is used for insulation in electrical cables and wiring due to its excellent dielectric strength. |

High-voltage applications | Provides reliable electrical insulation even in high-voltage scenarios. |

Heat shrink tubing | Offers protection for wires and components, especially in high-temperature environments. |

Applications in sensitive electronic components

FEP tubing safeguards sensitive electronic components from environmental factors such as moisture, UV radiation, and extreme temperatures. Its flame-retardant properties enhance safety by preventing fire spread along wiring systems. Furthermore, the tubing's transparency allows technicians to inspect connections easily, reducing maintenance errors.

FEP tubing provides reliable insulation and protection for wires and components.

It resists wear and tear, ensuring long-term durability.

The material's resistance to moisture and extreme temperatures enhances its longevity.

Medical and Pharmaceutical Industries

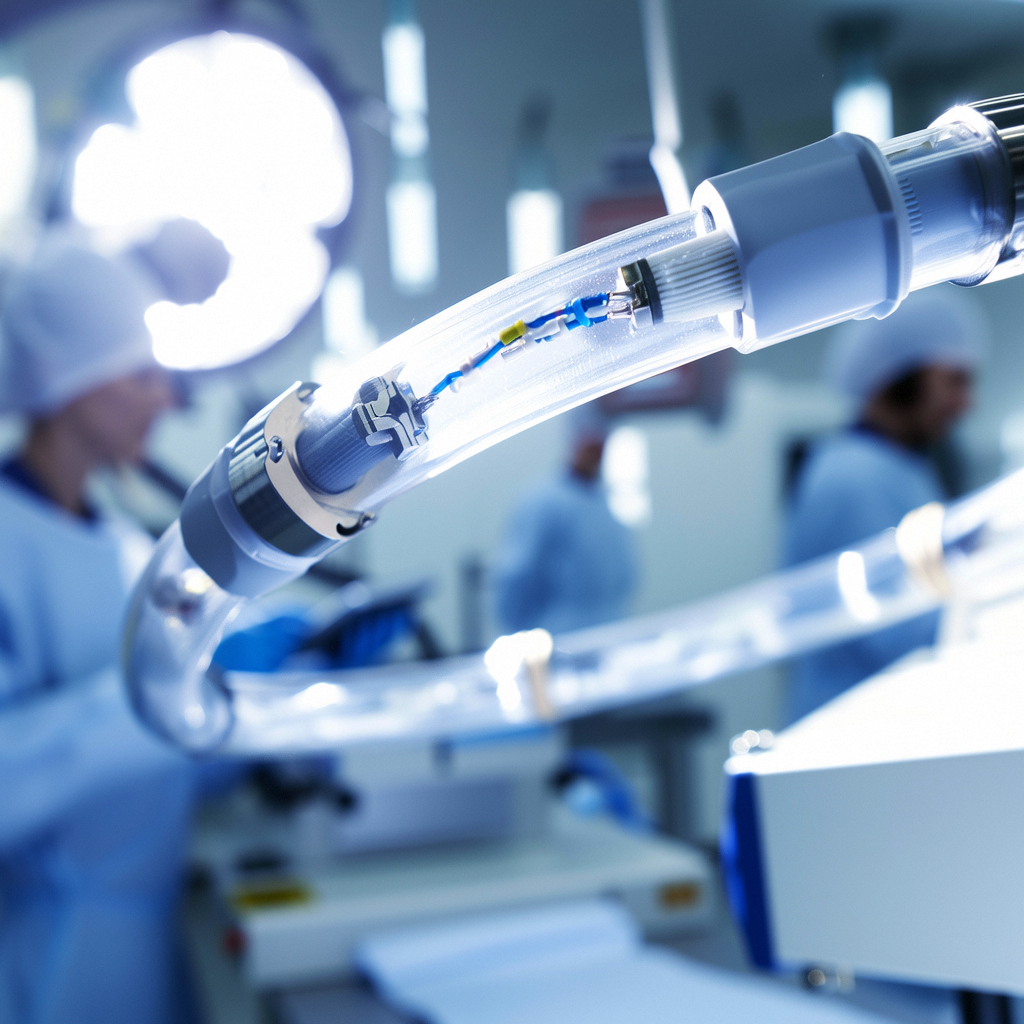

Tubing for chemical transport and medical devices

FEP tubing is widely used in medical and pharmaceutical applications due to its non-porous surface and chemical resistance. It ensures sterile fluid transfer in bioprocessing systems and chemical production lines. Its compliance with FDA regulations makes it suitable for medical devices and drug delivery systems.

Coronary Angioplasty: FEP tubing aids in the precise manipulation of guidewires and balloon catheters.

Intravascular Imaging: Used in imaging catheters for detailed assessments of coronary anatomy.

Drug Delivery Systems: Ensures controlled release of therapeutic agents.

Sterilization and biocompatibility benefits

The non-reactive nature of FEP tubing supports hygiene standards in healthcare settings. Its transparency allows operators to visually inspect fluid flow without compromising sterility. These properties, combined with its durability and longevity, make it a preferred choice for medical applications.

The non-porous surface prevents contamination.

FEP tubing complies with FDA regulations, ensuring safety in medical environments.

Aerospace and Automotive Industries

High-performance insulation in extreme environments

FEP tubing excels in aerospace and automotive industries due to its ability to withstand extreme conditions. It resists aviation fuels, hydraulic fluids, and high temperatures, ensuring reliable performance in critical systems. Its flame-retardant nature enhances safety by preventing fire spread, which is vital in aviation.

FEP tubing is used in fuel lines for its chemical resistance.

It provides exceptional protection for wires and sensitive components.

Its thermal stability ensures durability during extreme temperature variations.

Lightweight and durable solutions

FEP tubing offers lightweight and durable solutions for aerospace and automotive applications. Its flexibility and resistance to tearing make it easy to handle and install. Additionally, its low friction properties facilitate optimal fluid flow, reducing contamination risks.

Chemical resistance makes it ideal for industrial applications involving aggressive chemicals.

High-temperature suitability ensures longevity in demanding environments.

Flexibility and durability enhance its usability in complex systems.

Industrial Applications

Use in Chemical Processing and Fluid Handling

FEP tubing plays a vital role in chemical processing facilities. Its exceptional chemical resistance ensures the safe transfer of corrosive substances, preventing leaks and contamination. This reliability makes it indispensable in environments where aggressive chemicals are handled daily. For example, chemical production lines rely on FEP tubing to transport corrosive liquids and gases efficiently. The tubing's non-reactive surface maintains its integrity even when exposed to highly acidic or basic solutions, ensuring consistent performance over time.

In fluid handling applications, FEP tubing demonstrates unmatched durability. Its smooth interior surface minimizes friction, allowing for the seamless flow of liquids and gases. This property is particularly valuable in systems requiring precise fluid control, such as those found in pharmaceutical manufacturing or laboratory equipment. The tubing's ability to withstand high pressures further enhances its suitability for demanding industrial processes.

Applications in Harsh Industrial Environments

FEP tubing thrives in harsh industrial environments where other materials often fail. Its resistance to extreme temperatures, chemicals, and mechanical stress makes it a preferred choice across various industries:

Chemical Processing: Ensures the safe transfer of corrosive chemicals without degradation.

Pharmaceutical Industry: Supports sterile fluid transfer in bioprocessing systems.

Food and Beverage Sector: Maintains hygiene standards during the handling of food items.

Aerospace Engineering: Protects fuel lines from aviation fuels and extreme conditions.

Laboratory Equipment: Facilitates accurate fluid transfer in chromatography systems.

These applications highlight the versatility of FEP tubing. Its ability to perform reliably under challenging conditions reduces maintenance costs and downtime, making it a cost-effective solution for industries requiring high-performance materials.

Tip: FEP tubing's unique properties, such as chemical resistance and thermal stability, make it an essential component in industries where safety and efficiency are paramount.

Limitations of FEP Dielectric Tubing

Cost Considerations

Higher cost compared to some alternatives

FEP dielectric tubing offers exceptional performance, but its cost is significantly higher than many other insulation materials. This price difference can impact budget-sensitive projects, especially when large quantities are required. For instance, industries that prioritize cost-efficiency may opt for alternatives like PVC or silicone, which provide adequate insulation at a lower price point.

Cost Factor | Description |

|---|---|

Higher Cost | FEP tubing tends to be more expensive than other types of plastic tubing, which can impact budget-sensitive projects. |

Environmental Concerns | The production and disposal of FEP raise environmental and health concerns due to harmful chemicals involved. |

Limited Temperature Range | FEP is not suitable for extremely high-temperature applications due to its lower melting point compared to other plastics. |

Situations where cost may outweigh benefits

Certain applications may not justify the expense of FEP tubing. For example:

Budget-sensitive projects requiring large quantities of tubing.

Applications where gas containment is critical, as FEP is somewhat permeable to gases.

Scenarios needing efficient heat transfer, where FEP's low thermal conductivity is a disadvantage.

While FEP tubing provides long-term protection and excellent resistance to weathering, its cost can outweigh its benefits in less demanding environments.

Mechanical Strength

Lower mechanical strength compared to some materials

FEP tubing exhibits good tensile strength but lacks the rigidity of metals or high-performance plastics like PFA. This limitation restricts its use in applications requiring structural support or high mechanical strength. For instance, industries needing robust materials for heavy-duty operations often select alternatives with greater mechanical durability.

Applications requiring additional reinforcement

In scenarios demanding enhanced mechanical strength, FEP tubing may require reinforcement. For example, in high-pressure systems, additional layers or external supports are necessary to ensure safety and reliability. While FEP tubing excels in chemical resistance and thermal stability, its mechanical limitations make it less suitable for heavy-duty applications.

Availability and Customization

Limited availability in certain regions

FEP tubing's specialized nature can lead to limited availability in some regions. Industries in remote areas may face challenges sourcing this material, especially in custom sizes or specifications. This limitation can delay projects and increase costs due to shipping and handling requirements.

Challenges in sourcing custom sizes or specifications

Customizing FEP tubing to meet specific requirements can be challenging. Manufacturers may need to invest additional time and resources to produce tubing in non-standard dimensions. This can impact industries requiring precise specifications, such as medical or aerospace applications. Despite these challenges, selecting the best heat shrink tubing often depends on balancing performance with availability.

Note: While FEP tubing offers unmatched protection and safety, its limitations in cost, mechanical strength, and availability highlight the importance of evaluating application-specific needs before making a selection.

FEP dielectric tubing stands out as a reliable solution for industries requiring advanced insulation. Its exceptional chemical resistance, thermal stability, and electrical properties make it ideal for demanding applications. While its cost and mechanical strength may pose challenges, these factors rarely outweigh its benefits in high-performance environments. Industries such as aerospace, medical, and electronics continue to rely on FEP for its unmatched durability and versatility. For those seeking dependable insulation materials, FEP remains a top choice.

FAQ

What makes FEP dielectric tubing unique compared to other materials?

FEP dielectric tubing stands out due to its exceptional chemical resistance, thermal stability, and electrical insulation. Its ability to perform reliably in extreme environments makes it a preferred choice for industries like aerospace, electronics, and medical applications.

Can FEP tubing be used in high-temperature environments?

Yes, FEP tubing operates effectively in temperatures ranging from -200°C to 200°C. This wide range ensures its suitability for applications requiring thermal stability, such as aerospace fuel lines and industrial machinery.

Is FEP tubing safe for medical applications?

FEP tubing complies with FDA regulations, making it safe for medical and pharmaceutical use. Its non-porous surface prevents contamination, while its biocompatibility ensures reliable performance in drug delivery systems and medical devices.

How does FEP tubing compare to PTFE in flexibility?

FEP tubing offers greater flexibility than PTFE, making it ideal for applications requiring precise installations in confined spaces. This property enhances its usability in industries like automotive and laboratory equipment.

Are there any limitations to using FEP dielectric tubing?

FEP tubing has a higher cost compared to alternatives like PVC or silicone. It also exhibits lower mechanical strength, requiring reinforcement in heavy-duty applications. Additionally, sourcing custom sizes may pose challenges in certain regions.

Tip: Evaluate the specific requirements of your application to determine if FEP tubing's advantages outweigh its limitations.

See Also

Understanding FEP's Importance in Medical Device Insulation

Exploring FEP's Advantages for Medical Device Insulation

FEP Heat Shrink Tubing Versus Alternative Materials in Radiation Therapy

FEP Heat Shrink Tubing Compared to Polyolefins for Electrosurgical Instruments

Evaluating FEP Heat Shrink Tubing Against PTFE for Chemical Durability