What is 2:1 Shrink Ratio PET Tubing and How Does It Work

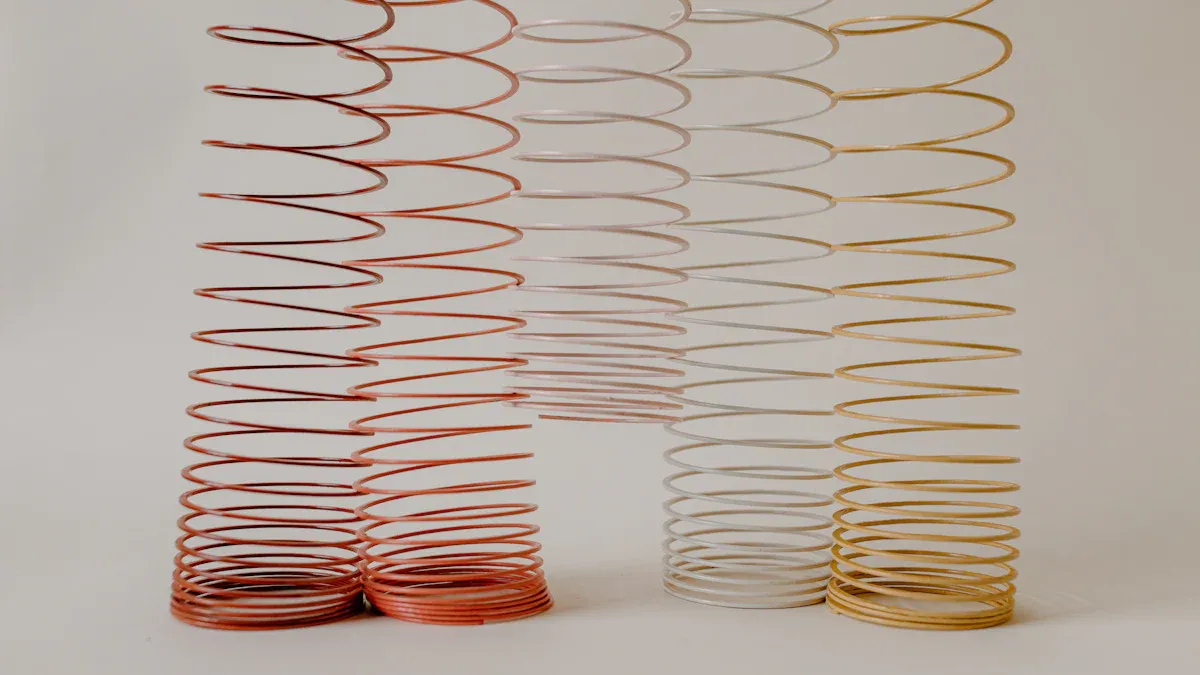

2:1 shrink ratio PET tubing medical grade refers to a specialized type of heat-shrinkable tubing designed to contract to half its original diameter when exposed to heat. This tubing is crafted from polyethylene terephthalate (PET), a durable and flexible material widely used in demanding environments. Its ability to shrink precisely ensures a snug fit, making it indispensable for protecting sensitive components in medical devices.

Recent market data highlights the importance of 2:1 shrink ratio PET tubing:

The 2:1 expansion ratio segment dominated with 45% of the revenue share in 2023, showcasing its widespread application.

The medical industry drives significant growth, fueled by the rising demand for insulated and protected medical devices.

This tubing plays a critical role in medical-grade applications, offering reliable insulation, reinforcement, and protection for tools and equipment.

Key Takeaways

2:1 shrink ratio PET tubing shrinks to half its size when heated. This makes it fit tightly on medical devices.

The tubing is safe to use with human tissue in medical settings.

It is strong and resists chemicals, lasting a long time even in tough conditions.

Its flexibility means fewer sizes are needed, making storage easier and cheaper.

High-quality PET tubing improves medical device reliability and lowers costs.

What is 2:1 Shrink Ratio PET Tubing?

Definition of 2:1 shrink ratio

The term "2:1 shrink ratio" refers to the ability of heat shrink tubing to reduce its diameter to half its original size when exposed to heat. This characteristic ensures a tight and secure fit around the object it covers, such as wires, cables, or medical instruments. Heat shrink tubing with a 2:1 shrink ratio is particularly valued for its precision and adaptability. It can conform to irregular shapes, providing reliable insulation and protection in various environments. Both single-wall and dual-wall options are available, offering flexibility for different applications.

Key properties of PET as a material

Polyethylene terephthalate (PET) is a versatile material known for its durability, flexibility, and resistance to environmental factors. These properties make PET an ideal choice for manufacturing heat shrink tubing. Key attributes of PET include:

Biocompatibility: PET is safe for use in medical-grade applications, ensuring it does not cause adverse reactions when in contact with human tissue.

Thermal stability: It can withstand high temperatures without losing its structural integrity, making it suitable for heat shrink processes.

Chemical resistance: PET resists damage from exposure to oils, solvents, and other chemicals commonly encountered in medical and industrial settings.

Dimensional control: The material allows for precise manufacturing, ensuring consistent performance across various applications.

These properties enable PET tubing to meet the stringent requirements of medical devices and other critical uses.

Importance of 2:1 shrink ratio in medical-grade tubing

The 2:1 shrink ratio plays a crucial role in the effectiveness of PET tubing for medical-grade applications. Its ability to shrink uniformly ensures a snug fit, which is essential for protecting sensitive components in medical devices. This tubing provides insulation for wires in catheters, reinforcement for surgical tools, and protective coatings for delicate instruments. Its biocompatibility and sterile nature further enhance its suitability for medical use.

Additionally, the 2:1 shrink ratio allows for versatility in applications, accommodating a wide range of sizes and shapes. This adaptability reduces the need for multiple tubing sizes, streamlining inventory management and lowering costs. The tubing's environmental resistance ensures long-term reliability, even in demanding conditions.

Did you know? The 2:1 shrink ratio PET tubing holds the largest market share in the heat shrink tubing industry due to its widespread use in medical and industrial applications. Its combination of flexibility, precision, and durability makes it a preferred choice for professionals worldwide.

How Does 2:1 Shrink Ratio PET Tubing Work?

The heat-shrink process explained

The heat-shrink process is a critical mechanism that allows heat shrink tubing to function effectively. This process begins with the manufacturing of polyethylene terephthalate (PET) fibers through polymerization, melting, extrusion, and spinning. During production, the tubing is expanded and set in its enlarged form. When exposed to heat, the tubing contracts to its original size, creating a tight and secure fit around the object it covers.

The thermal shrinkage properties of PET fibers enhance their performance. As temperature increases, the intermolecular bonds within the material strengthen, improving stability and durability. This process not only ensures a snug fit but also enhances the tubing's resistance to environmental stressors. The heat-setting stage further stabilizes the material, making it suitable for demanding applications, including medical devices.

Aspect | Details |

|---|---|

Type of Fiber | Thermal shrinkage fibers, including PET fibers derived from polyethylene terephthalate (PET). |

Thermal Shrinkage Properties | Exhibits contraction with increased temperature, enhancing crack resistance in concrete. |

Manufacturing Process | Involves polymerization of terephthalic acid and ethylene glycol, followed by melting, extrusion, and spinning. |

Heat-Setting Stage | Corresponds to the thermal shrinkage process, enhancing intermolecular bonding and fiber stability. |

Thermal stability and flexibility of PET tubing

PET tubing exhibits exceptional thermal stability and flexibility, making it ideal for heat shrink tubing. Research demonstrates a significant improvement in thermal properties, with a ΔTm value of 16.7 °C. This stability ensures the tubing maintains its structural integrity even under high temperatures. Differential scanning calorimetry (DSC) studies reveal an enthalpy of melting (∆Hf) at 140.1 J/g, highlighting its ability to withstand thermal stress.

Flexibility is another key attribute of PET tubing. Structural modifications enhance the flexibility of the PET binding cleft, as shown by measurable changes in root-mean-square fluctuation (RMSF) results. This flexibility allows the tubing to conform to irregular shapes, ensuring reliable insulation and protection for medical devices and other applications.

Benefits of the 2:1 shrink ratio in medical applications

The 2:1 shrink ratio offers numerous advantages in medical applications. It ensures a precise fit, which is essential for protecting sensitive components in medical devices. This ratio allows the tubing to accommodate a wide range of sizes and shapes, reducing the need for multiple tubing variants. Its thermal stability and flexibility make it suitable for insulating wires in catheters, reinforcing surgical tools, and protecting delicate instruments.

The tubing's ability to shrink uniformly enhances its reliability in critical medical environments. Its biocompatibility ensures safety for use in surgical and diagnostic devices. Additionally, the 2:1 shrink ratio simplifies inventory management, making it a cost-effective solution for medical-grade applications.

Medical Applications of 2:1 Shrink Ratio PET Tubing

Catheter protection and reinforcement

Heat shrink tubing plays a vital role in catheter protection and reinforcement. Catheters, which are essential in many medical procedures, require a durable and reliable covering to ensure their functionality and safety. The 2:1 shrink ratio PET tubing provides a snug fit around the catheter, shielding it from external damage and wear. This tubing enhances the catheter's structural integrity, reducing the risk of kinks or breaks during use.

The biocompatibility of PET tubing ensures it remains safe for contact with human tissue, a critical requirement for medical applications. Its thermal stability allows it to endure sterilization processes without compromising its performance. Additionally, the tubing's flexibility enables it to conform to the catheter's shape, ensuring seamless integration with the device. These qualities make it an indispensable component in modern catheter design and manufacturing.

Insulation for surgical tools and devices

Surgical tools and devices often require insulation to maintain their performance and safety. Heat shrink tubing provides an effective solution for this need. The 2:1 shrink ratio ensures a precise fit, creating a protective barrier around the tool or device. This insulation prevents electrical interference, enhances grip, and protects sensitive components from environmental factors.

For surgical tools, PET tubing offers excellent resistance to chemicals and high temperatures, ensuring long-term reliability. Its ability to shrink uniformly around irregular shapes makes it suitable for a wide range of surgical instruments. By providing insulation for surgical tools, this tubing contributes to safer and more efficient medical procedures.

Wire harnessing in medical equipment

Wire harnessing in medical equipment demands precision and durability. Heat shrink tubing simplifies this process by securely bundling and protecting wires within medical devices. The 2:1 shrink ratio allows the tubing to adapt to various wire sizes, ensuring a tight and organized fit. This reduces the risk of wire damage, short circuits, or interference during operation.

PET tubing's chemical resistance and thermal stability make it ideal for use in medical equipment. It withstands exposure to sterilization methods and harsh environments, ensuring the longevity of the wire harness. Additionally, its flexibility allows it to accommodate complex wiring configurations, making it a preferred choice for engineers designing advanced medical devices.

Tip: Proper wire harnessing with heat shrink tubing not only improves the reliability of medical equipment but also simplifies maintenance and repairs.

Other medical-grade applications

2:1 shrink ratio PET tubing finds use in a variety of specialized medical applications due to its versatility and reliability. Beyond catheter protection, surgical tool insulation, and wire harnessing, this tubing supports numerous other critical functions in healthcare.

Endoscope Component Protection:

Heat shrink tubing plays a vital role in safeguarding the delicate components of endoscopes. These devices require precise insulation to protect internal wiring and optical fibers from damage during use. The tubing's ability to conform to irregular shapes ensures a secure fit, enhancing the durability and performance of endoscopes in diagnostic and surgical procedures.Drug Delivery Systems:

PET tubing is often used in drug delivery devices, such as infusion pumps and inhalers. Its biocompatibility ensures safety when in contact with medications or biological fluids. The tubing provides a protective layer that prevents contamination and maintains the structural integrity of these devices, even under repeated use.Electrosurgical Instrument Insulation:

Electrosurgical instruments rely on heat shrink tubing for insulation to prevent electrical leakage and ensure patient safety. The tubing's thermal stability allows it to withstand the high temperatures generated during electrosurgical procedures. Its chemical resistance also protects the instruments from exposure to sterilization agents.Implantable Device Encapsulation:

Heat shrink tubing is sometimes used to encapsulate components of implantable devices, such as pacemakers or neurostimulators. The tubing provides an additional layer of protection against moisture and environmental factors, ensuring the longevity and reliability of these life-saving devices.Sterilization Indicator Sleeves:

In sterilization processes, heat shrink tubing can serve as indicator sleeves that change color to confirm successful sterilization. This application highlights the tubing's ability to withstand extreme temperatures while maintaining its structural integrity.

Note: The adaptability of heat shrink tubing makes it an indispensable material in the medical field. Its ability to provide insulation, protection, and reinforcement ensures the safe and effective operation of various medical devices.

These additional applications demonstrate the broad utility of 2:1 shrink ratio PET tubing in healthcare. Its unique properties, including thermal stability, flexibility, and biocompatibility, make it a preferred choice for medical-grade solutions.

Why is 2:1 Shrink Ratio PET Tubing a Preferred Choice in the Medical Field?

Durability and resistance to chemicals

2:1 shrink ratio PET tubing offers exceptional durability, making it ideal for demanding medical environments. Its robust structure resists wear and tear, ensuring long-term performance even under continuous use. This durability proves essential for medical devices that require reliable insulation and protection. Additionally, the tubing demonstrates excellent resistance to chemicals, including oils, solvents, and disinfectants. This property allows it to maintain its integrity when exposed to sterilization equipment or harsh cleaning agents.

The chemical resistance of PET tubing also ensures compatibility with various medical applications. For instance, it protects surgical instruments and diagnostic tools from corrosion caused by exposure to bodily fluids or sterilization processes. This combination of durability and chemical resistance makes heat shrink tubing a trusted choice for healthcare professionals.

Biocompatibility and safety for medical use

Biocompatibility is a critical factor in selecting materials for medical-grade devices. PET tubing meets stringent safety standards, ensuring it does not cause adverse reactions when in contact with human tissue. Clinical evaluations confirm its compliance with key regulations, as shown below:

Standard | Description |

|---|---|

Framework for biological evaluation of medical devices, including risk management and biological safety assessment. | |

FDA Regulations | Requires documentation of material sourcing and sterilization compatibility to ensure safety and performance. |

CE Marking | Compliance under EU Medical Device Regulation, necessitating expanded clinical evaluations for diagnostic devices. |

These certifications highlight the tubing's suitability for use in sterile environments and its compatibility with medical-grade sterilization equipment. Its biocompatibility ensures patient safety, making it a reliable material for surgical tools, catheters, and other critical devices.

Customizability for medical applications

The versatility of 2:1 shrink ratio PET tubing allows it to adapt to a wide range of medical applications. Its ability to shrink uniformly ensures a precise fit around components of varying shapes and sizes. This adaptability reduces the need for multiple tubing variants, simplifying inventory management for healthcare facilities.

Manufacturers can customize the tubing to meet specific requirements, such as varying wall thicknesses, lengths, and colors. This flexibility supports the development of specialized medical devices, including surgical instruments and diagnostic tools. Additionally, the tubing's compatibility with advanced sterilization methods ensures it remains sterile and ready for use in critical procedures.

The customizability of heat shrink tubing enhances its value in the medical field. Its ability to meet diverse needs while maintaining high performance makes it an indispensable material for modern healthcare solutions.

Cost-effectiveness and efficiency

2:1 shrink ratio PET tubing provides a cost-effective solution for various medical needs. Its ability to shrink uniformly reduces the need for multiple tubing sizes, simplifying inventory management. This versatility allows manufacturers to use a single type of tubing for different components, minimizing production costs. Heat shrink tubing also eliminates the need for additional adhesives or fasteners, further lowering expenses.

The durability of PET tubing contributes to its efficiency. Its resistance to wear, chemicals, and high temperatures ensures long-term performance, reducing the frequency of replacements. Medical devices that incorporate this tubing benefit from enhanced reliability, which translates to fewer maintenance requirements. This durability makes it an economical choice for healthcare facilities aiming to optimize their budgets.

Heat shrink tubing also streamlines manufacturing processes. Its precise shrink ratio ensures a snug fit around components, reducing assembly time. This efficiency allows manufacturers to produce medical devices more quickly, meeting the growing demand for advanced healthcare solutions. The tubing’s compatibility with sterilization methods ensures it remains ready for use, saving time during preparation.

In addition to cost savings, PET tubing supports sustainable practices. Its long lifespan reduces material waste, aligning with eco-friendly manufacturing goals. By combining affordability, reliability, and environmental benefits, heat shrink tubing offers a comprehensive solution for medical applications.

Tip: Choosing high-quality heat shrink tubing can significantly reduce operational costs while maintaining the performance of medical devices.

2:1 shrink ratio PET tubing stands out as a reliable solution for insulation, protection, and reinforcement in critical environments. Its ability to shrink uniformly ensures a precise fit, making it indispensable for medical devices. Applications like catheter reinforcement, surgical tool insulation, and wire harnessing highlight its versatility and benefits. The tubing’s durability, biocompatibility, and cost-effectiveness further solidify its role in healthcare. By meeting stringent standards, it continues to support advancements in medical technology and beyond.

FAQ

What does the 2:1 shrink ratio mean for PET tubing?

The 2:1 shrink ratio indicates that the tubing contracts to half its original diameter when heated. This property ensures a tight fit around components, providing insulation, protection, and reinforcement in medical devices.

Is 2:1 shrink ratio PET tubing safe for medical applications?

Yes, PET tubing is biocompatible and meets stringent safety standards like ISO 10993-1. It does not cause adverse reactions when in contact with human tissue, making it suitable for catheters, surgical tools, and implantable devices.

Can PET tubing withstand sterilization processes?

PET tubing exhibits excellent thermal stability and chemical resistance. It endures high temperatures and exposure to sterilization agents without compromising its structural integrity, ensuring reliability in medical environments.

How customizable is 2:1 shrink ratio PET tubing?

Manufacturers can tailor PET tubing to specific needs, including varying lengths, wall thicknesses, and colors. Its adaptability supports diverse medical applications, from catheter reinforcement to wire harnessing in diagnostic equipment.

Why is PET tubing cost-effective for healthcare facilities?

Its durability reduces replacement frequency, while its versatility minimizes the need for multiple tubing variants. PET tubing also streamlines manufacturing and assembly processes, saving time and resources for healthcare providers.

See Also

Exploring FEP Tubing Featuring A 1.3:1 Shrink Ratio

Selecting The Ideal Ultra-Thin PET Heat Shrink Tubing

Essential Information About PET Heat Shrink Tubing In Electronics

The Importance Of Ultra-Thin PET Heat Shrink Tubing In Medicine

Key Uses Of Ultrathin-Wall PET Heat Shrink Tubing In Medicine